A Field Calculation Method for Determining the Influence of Power Plant Steam Turbine Exhaust Steam Pressure on Unit Economy

A technology of exhaust steam pressure and steam turbine, which is applied in the field of on-site measurement and calculation to determine the impact of power plant steam turbine exhaust pressure on unit economy, and can solve problems such as lack of verification means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

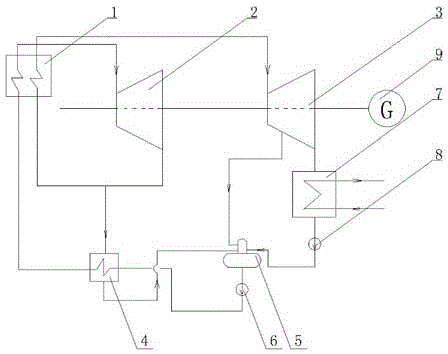

[0192] as attached figure 1 For a 660MW turbogenerator set shown, 1 is the boiler, 2 is the high-pressure cylinder, 3 is the medium-pressure cylinder, 4 is the high-pressure heater, 5 is the deaerator, 6 is the feed water pump, 7 is the condenser, 8 9 is a condensate pump, and 9 is a generator. In the basic operation mode of the unit, cancel the primary frequency regulation and AGC function of the unit, and keep the steam turbine inlet valve position of the unit constant, and collect the steam turbine exhaust pressure p of the unit in this stable state after the unit is running stably x1 , generator power P g1 , steam turbine inlet steam pressure P ms1 , Inlet steam temperature T ms1 , reheat steam inlet temperature T rh1 This is the data obtained in step 1; if the operating conditions permit, adjust the exhaust steam pressure of the steam turbine to a large extent, and collect the exhaust steam pressure of the steam turbine after the unit has operated to a stable operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com