A test method for measuring the interface strength of copper filled tsv holes

A technology of interface strength and testing method, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problem that the TSV-Cu structure is not easy to experiment, and achieve the effect of accurate strength, reliable results, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

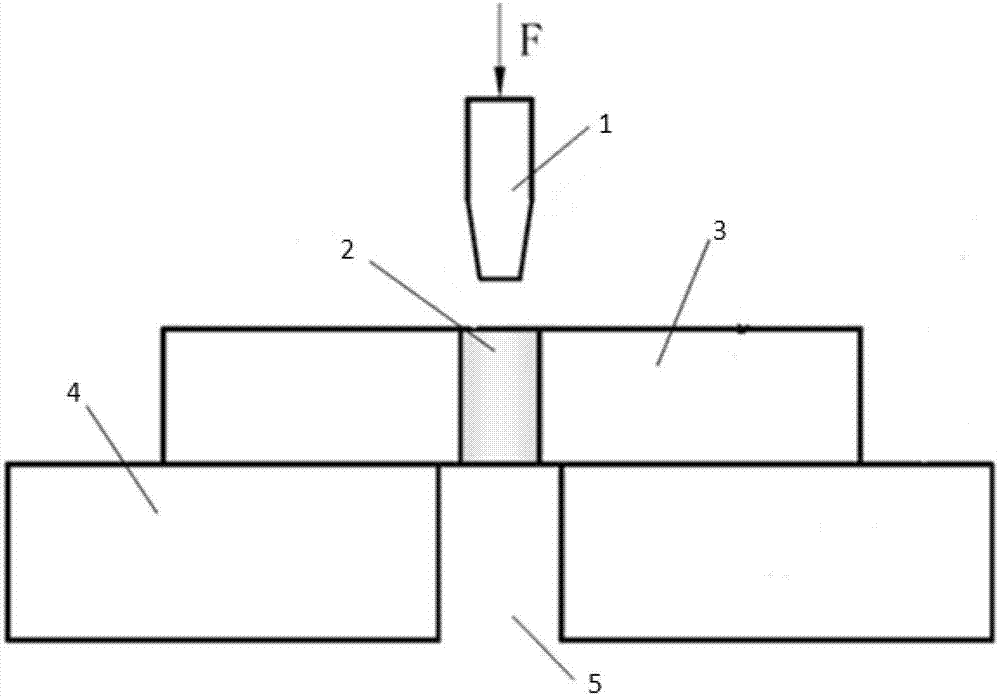

[0033] figure 1 It is a schematic diagram of the experimental principle. During the experiment, the sample carrier 4 is placed on the displacement stage of the nanoindenter, and the electroplated copper column 2 is aligned with the indenter 1 of the nanoindenter, and the electroplated copper column 2 is aligned with the carrier platform. Center the through hole 5, apply the force in the direction shown in the figure to press the electroplated copper column 2 out of the TSV through hole, and record the change of load and displacement during extrusion, and obtain the curve of load displacement. In the figure, the top of the electroplated copper column 2, that is, the end in contact with the indenter is the loading end of the electroplated copper column 2, and the bottom end of the electroplated copper column is the supporting end of the electroplated copper column 2.

[0034] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com