Touch screen and driving method thereof and display device

A technology of touch screen and touch drive electrodes, which is applied in the fields of instruments, computing, electrical digital data processing, etc. It can solve the problems of increasing the difficulty of pixel unit design, compressing the charging time of pixel units, and increasing the width of the overall module frame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

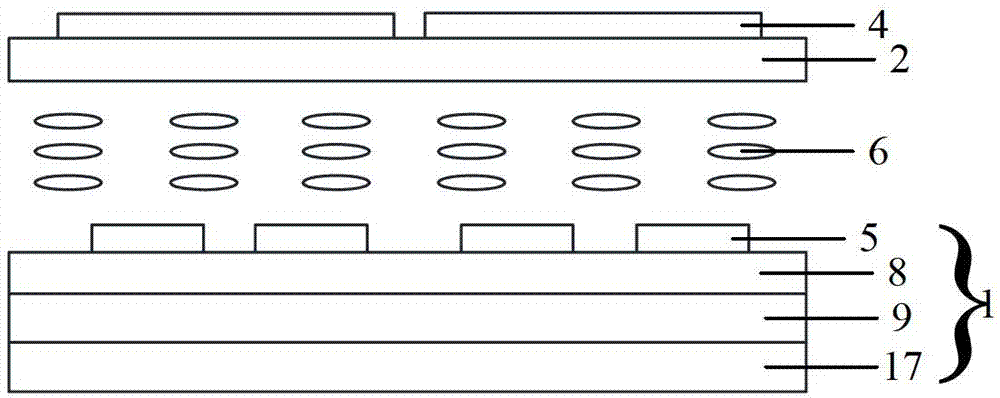

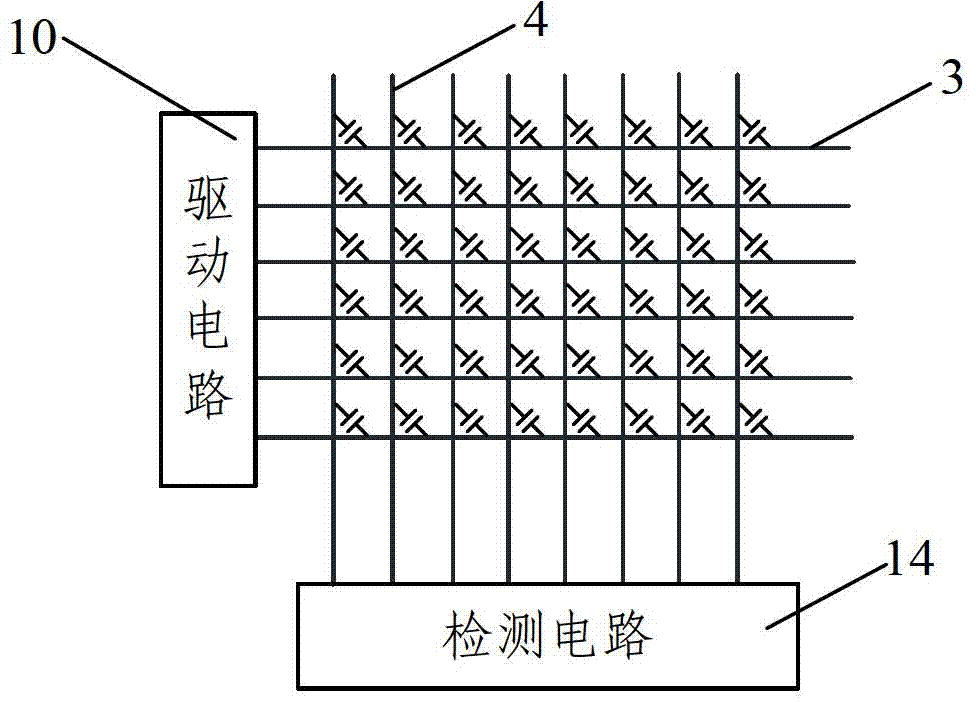

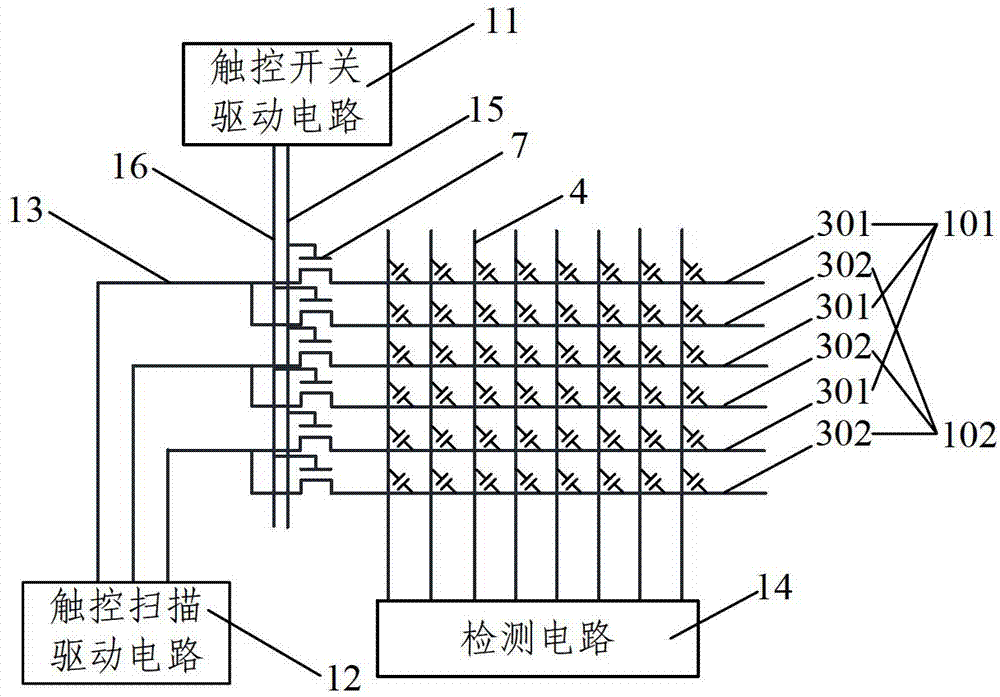

[0046] figure 1 Shown is a schematic longitudinal sectional view of the touch screen in the embodiment of the present invention; figure 2 Shown is a schematic diagram of the working principle of the touch screen in the embodiment of the present invention. combine figure 1 and figure 2 As shown, the touch screen in this embodiment specifically includes: an array substrate 1 and a color filter substrate 2 , and a liquid crystal layer 6 located between the array substrate 1 and the color filter substrate 2 . The array substrate 1 includes a base substrate 17 and a plurality of pixel units arranged in a matrix formed on the base substrate 17, the pixel units include a thin film transistor, a pixel electrode 5 and a common electrode 9, between the pixel electrode 5 and the common electrode 9 A passivation layer 8 is formed between them. Wherein, the common electrode 9 can be located above the pixel electrode 5, and also can be located below the pixel electrode 5, such as fig...

Embodiment 2

[0056] Based on the same inventive concept, this embodiment provides a display device, which includes the touch screen in Embodiment 1. Since only part of the touch detection points are touched within the display time of one frame, the display time of one frame is improved. The charging time of the pixel unit reduces the design difficulty of the pixel unit and ensures the display quality of the display device.

Embodiment 3

[0058] Correspondingly, this embodiment provides a touch screen driving method in Embodiment 1, which includes the step of dividing the display time of one frame of the touch screen into a display time period and a touch time period, and further includes:

[0059] Step S1, divide the multiple touch driving electrodes into multiple touch driving electrode groups according to certain rules;

[0060] Preferably, the plurality of touch driving electrodes are divided into two touch driving electrode groups, so as to complete the touch detection of all touch detection points within the display time of two consecutive frames of images, and ensure the accuracy of touch detection. Specifically, the touch driving electrodes can be wired along the row direction of the pixel unit, and then all odd-numbered rows of touch-driving electrodes are used as the first touch-driving electrode group, and all even-numbered rows of touch-driving electrodes are used as the second touch-driving electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com