Automatic calibration method for video monitoring system

A video monitoring system and automatic calibration technology, which is applied in closed-circuit television systems, image data processing, instruments, etc., can solve the problems of positioning accuracy, limitations, and cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

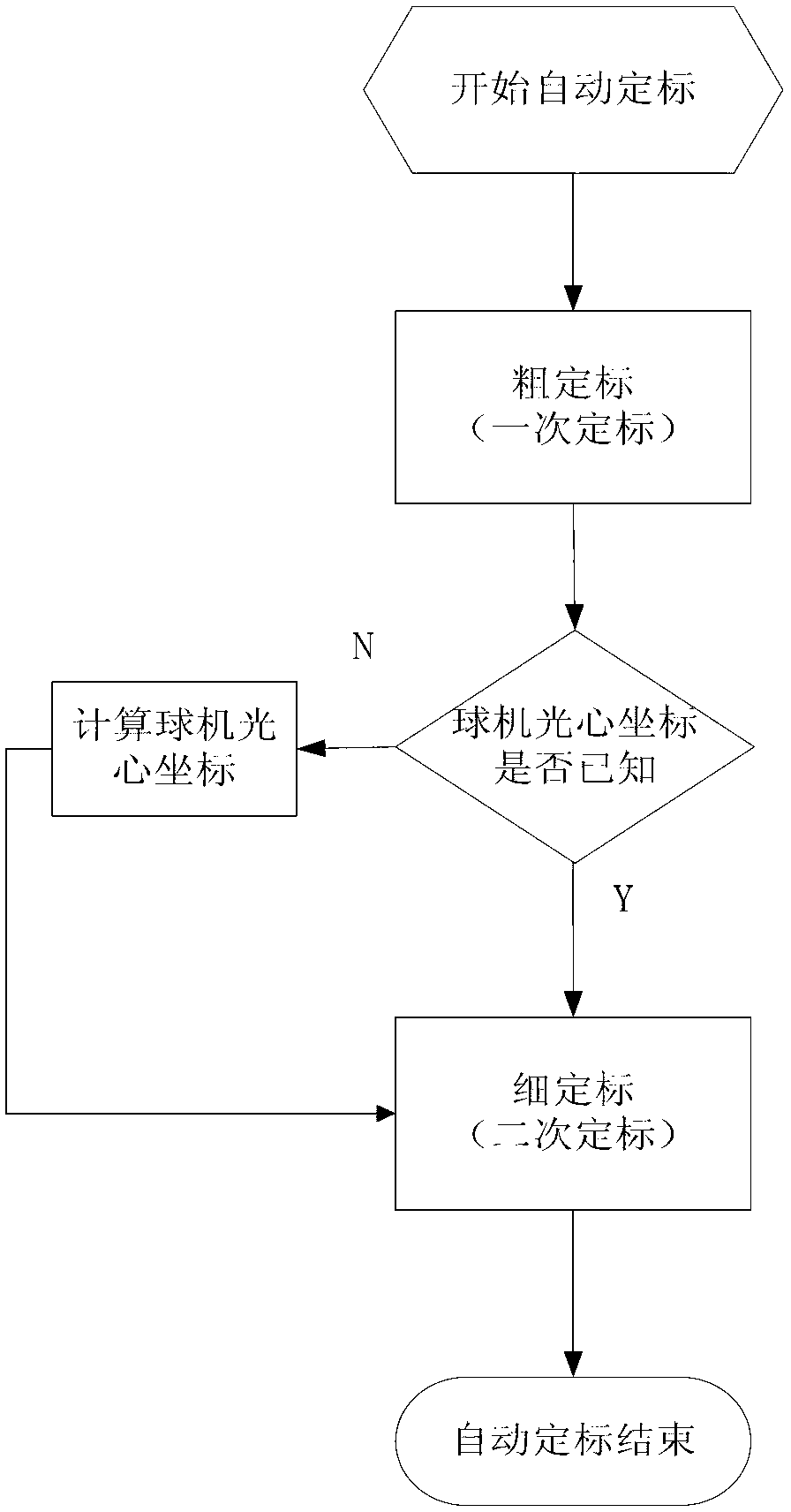

[0062] As mentioned above, the purpose of automatic calibration is to automatically establish the mapping relationship between the image coordinates of the gun camera and the physical coordinates of the dome camera. Such as figure 2 As shown, the preferred steps of the automatic calibration method of the present invention include: a rough calibration (primary calibration) step, a step of calculating the optical center image coordinates of the ball machine, and a fine calibration (secondary calibration) step, thereby completing the automatic target.

[0063] Each of the above steps will be described in detail below in conjunction with the accompanying drawings.

[0064] Coarse calibration (primary calibration) steps:

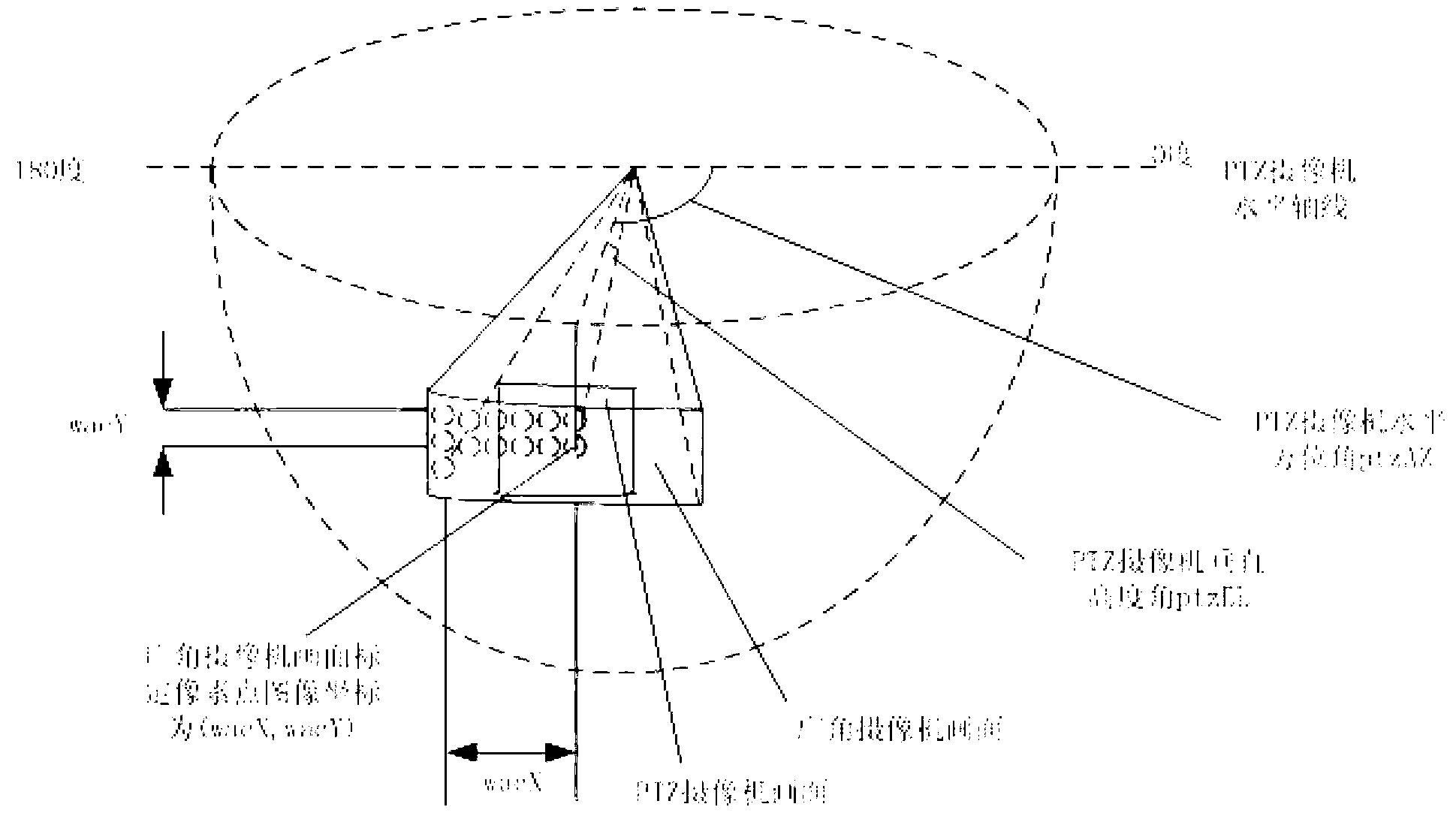

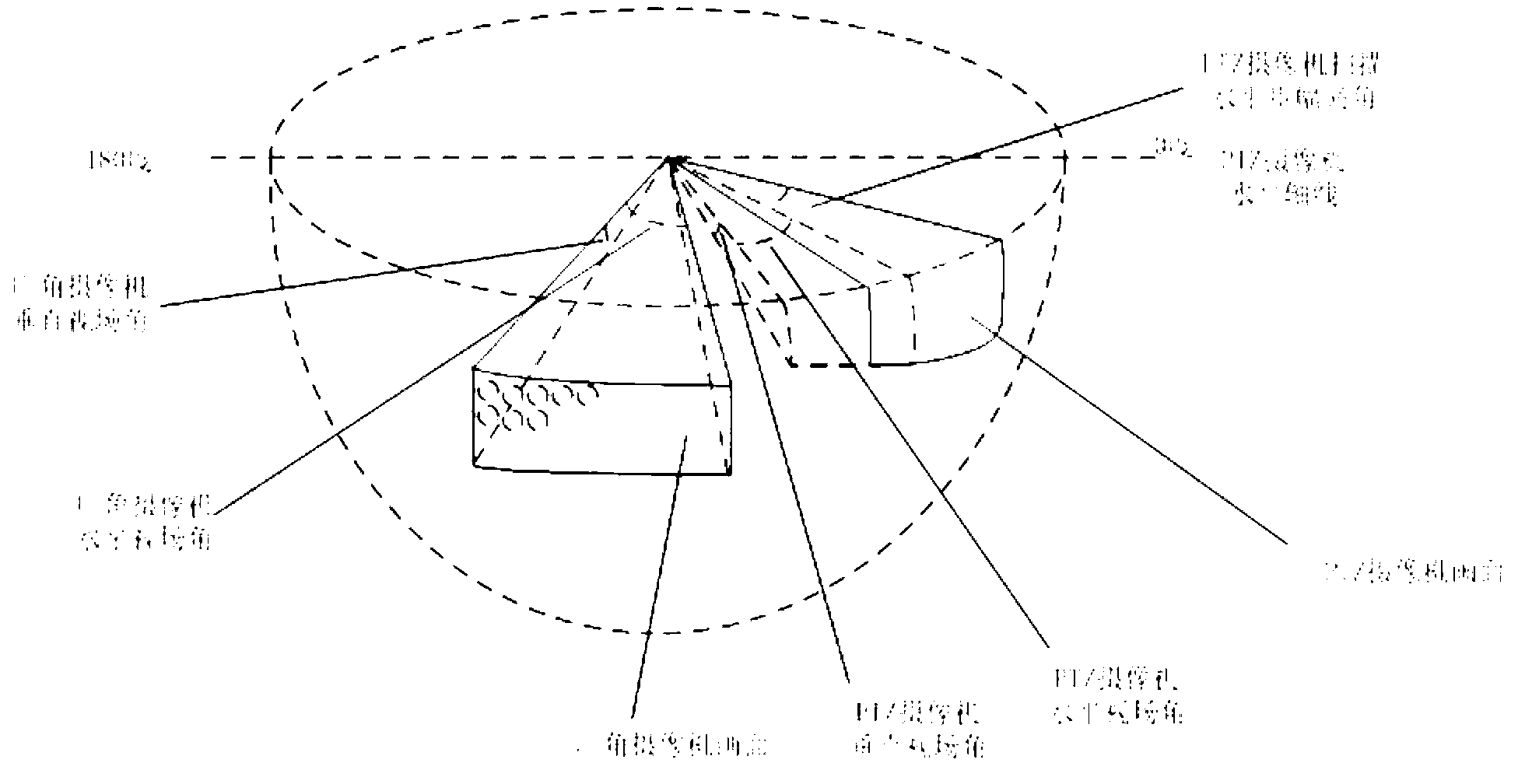

[0065] Such as image 3 As shown, since the relationship between the physical coordinates of the gun camera and the dome camera is not known at the beginning, the dome camera is controlled at a certain magnification, such as 1X magnification, and automaticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com