Method for controlling distribution of mesohigh electronic aluminum foil etching holes

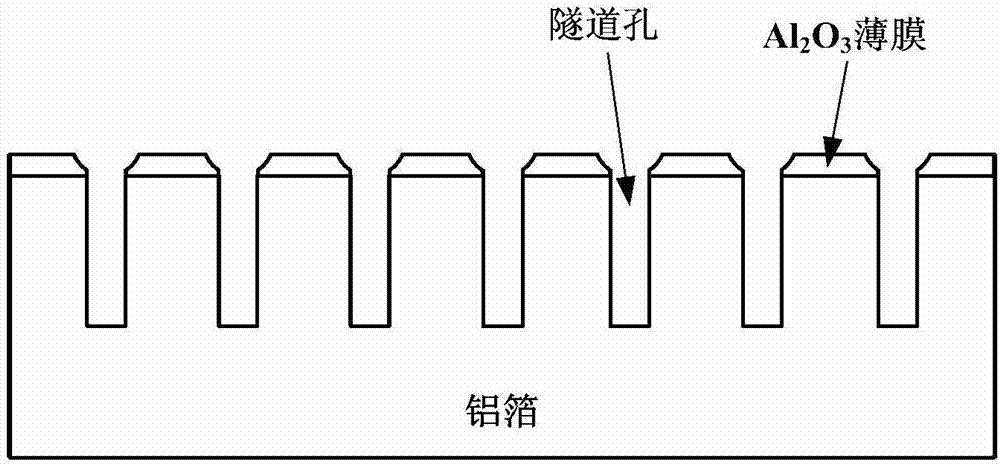

An electronic aluminum foil, medium and high voltage technology, applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of accelerated aluminum foil surface corrosion and thinning, many control factors, complex and cumbersome processes, etc., to achieve increased electrostatic specific capacitance, improved uniformity, The effect of reducing the probability of merging holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific operation steps are the same as the steps of the method for controlling the pitting distribution of medium and high voltage electronic aluminum foil described above, but the specific control technical conditions are different:

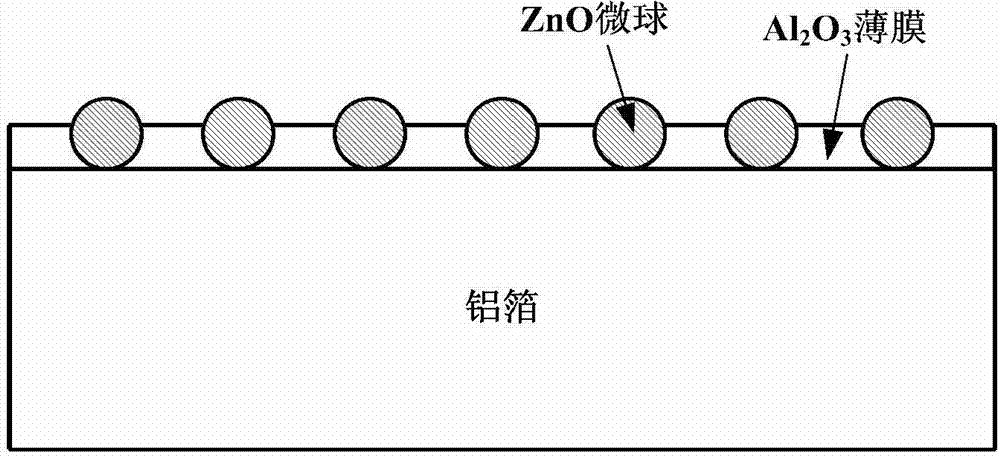

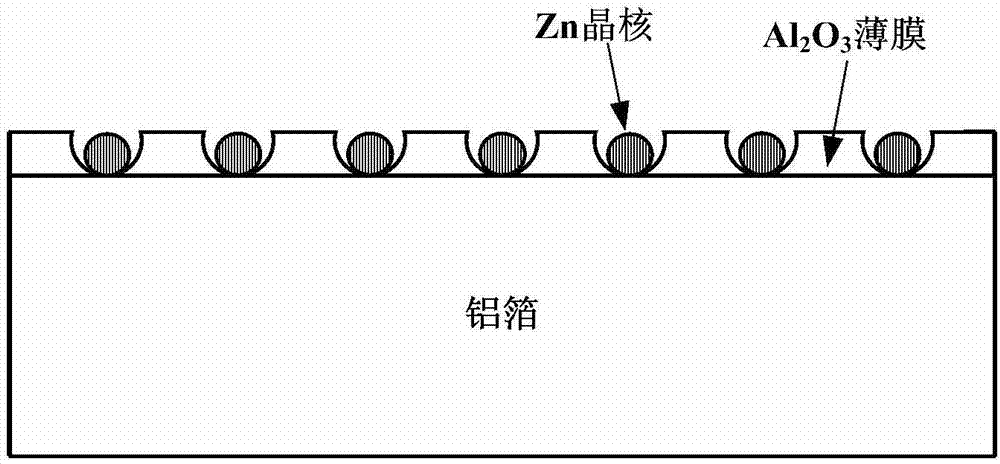

[0031] Preparation of Al with ZnO microspheres on the surface of aluminum foil 2 o 3 Thin-film aluminum foil, ZnO microspheres with a diameter of 0.3 μm, Al 2 o 3 The volume ratio to ZnO is 50:1, and the heat treatment condition is 500°C for 30s. Then, the same porosity corrosion, hole expansion corrosion, post-treatment and 520V chemical conversion treatment were carried out as in the comparative example.

Embodiment 2

[0033] The specific operation steps are the same as the steps of the method for controlling the pitting distribution of medium and high voltage electronic aluminum foil described above, but the specific control technical conditions are different:

[0034] Preparation of Al with ZnO microspheres on the surface of aluminum foil 2 o 3 Thin film of aluminum foil, ZnO microspheres with a diameter of 0.5 μm, Al 2 o 3 The volume ratio to ZnO is 50:1, and the heat treatment condition is 500°C for 30s. Then, the same porosity corrosion, hole expansion corrosion, post-treatment and 520V chemical conversion treatment were carried out as in the comparative example.

Embodiment 3

[0036] The specific operation steps are the same as the steps of the method for controlling the pitting distribution of medium and high voltage electronic aluminum foil described above, but the specific control technical conditions are different:

[0037] Preparation of Al with ZnO microspheres on the surface of aluminum foil 2 o 3 Thin film of aluminum foil, ZnO microspheres with a diameter of 1 μm, Al 2 o 3 The volume ratio to ZnO is 50:1, and the heat treatment condition is 500°C for 30s. Then, the same porosity corrosion, hole expansion corrosion, post-treatment and 520V chemical conversion treatment were carried out as in the comparative example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com