Wafer prealignment control method

A control method and pre-alignment technology, applied in the field of IC manufacturing and computer control, which can solve the problems of irregular gaps, not found, too many iterations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

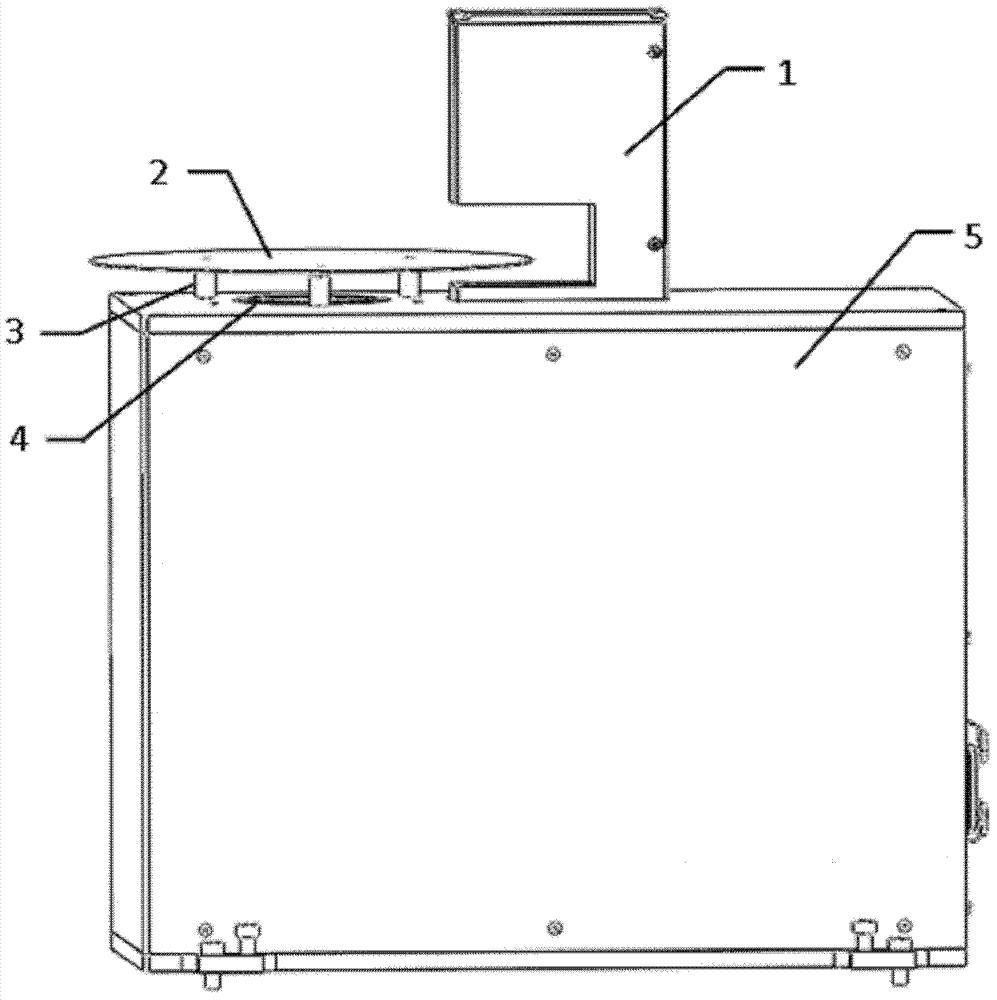

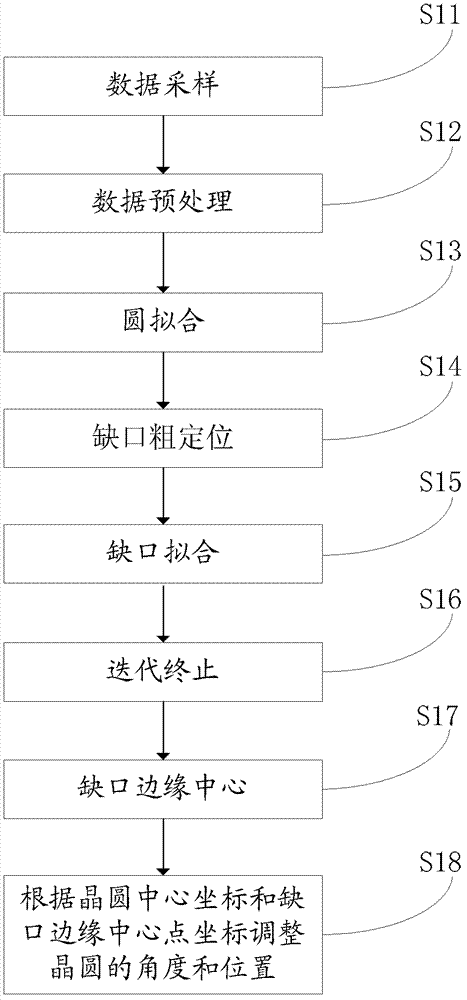

[0044] see figure 1 , in a preferred embodiment of the present invention, a wafer center pre-alignment equipment includes a control cabinet 5 for controlling the pre-aligned wafer 4; a top seat 3 for pre-aligning the wafer 4 The wafer 4 was previously supported; a negative pressure adsorption rotating device 4 provided on the control cabinet 5 is used to lift up the wafer 2 and extract the air between the tray and the wafer 2 to form a vacuum state , and drive the wafer 2 to rotate at the same time; a sensor 1 arranged on the control cabinet 5 is used to collect edge data of the wafer 4 and obtain the speed information of the corresponding negative pressure adsorption rotating device 4 . In one embodiment, the sensor is a single CCD sensor for collecting data at the edge of the wafer 2 .

[0045] The negative pressure adsorption rotating device 4 has a rotation center. The maximum range of the sensor 1 is L, and the distance from the maximum range to the negative pressure ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com