Asymmetric pressing control slab warping structure of multilayer printed circuit board

A multi-layer printing and circuit board technology, applied in the direction of printed circuit components, etc., can solve the problems of multi-layer printed circuit board board warping, and achieve the effect of reducing board warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

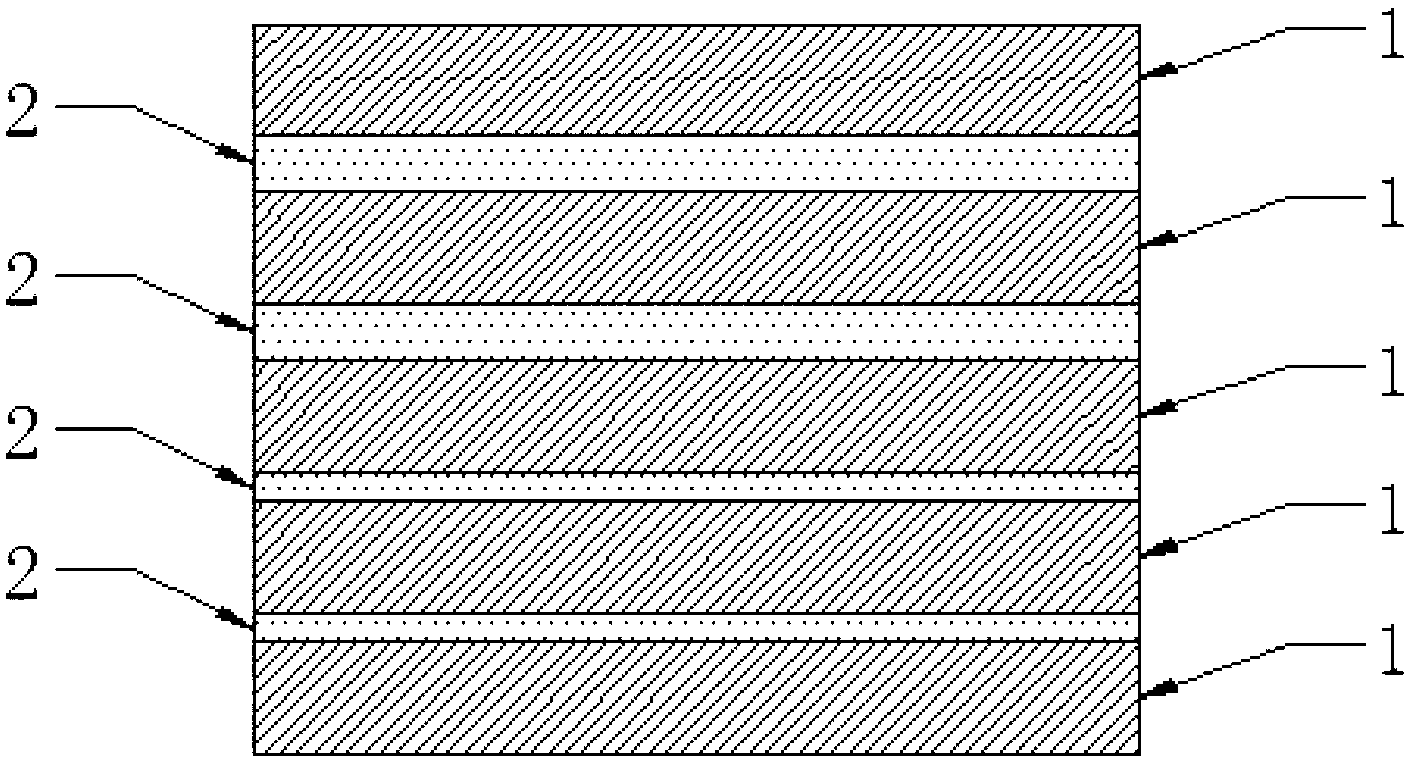

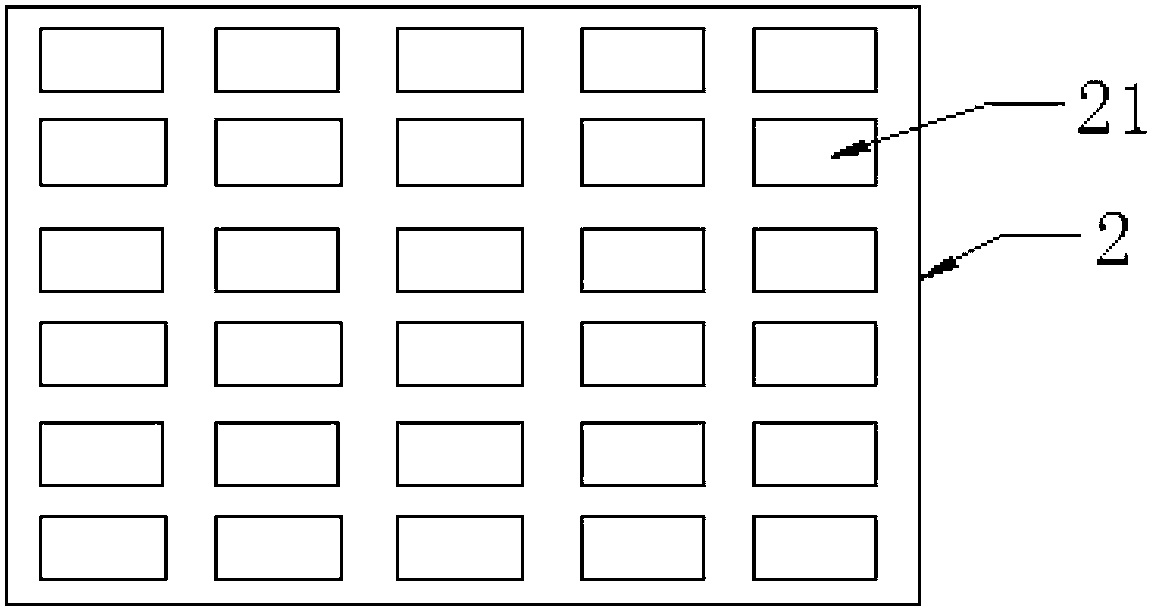

[0013] Embodiment: an asymmetric lamination control board warping structure of a multi-layer printed circuit board. There is a film layer 2 between adjacent circuit layers 1. The film layers from the top circuit layer to the center circuit layer are sorted in sequence, and the The film layers between the bottom line layer and the center line layer are sorted in order, and the two film layers with the same serial number are defined as relative film layers, and the thicknesses of the two film layers of each pair of opposite film layers are different, and the film layers of each layer There are several hollowed-out parts 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com