Manufacturing method for improving warpage of composite membrane plate

A production method and composite film technology, applied in the field of composite films, can solve the problems of increasing the reverse winding process and reducing the warpage of composite films, and achieve the effects of improving market competitiveness, facilitating accurate absorption, and expanding the operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: Composite membrane adopts following method to make:

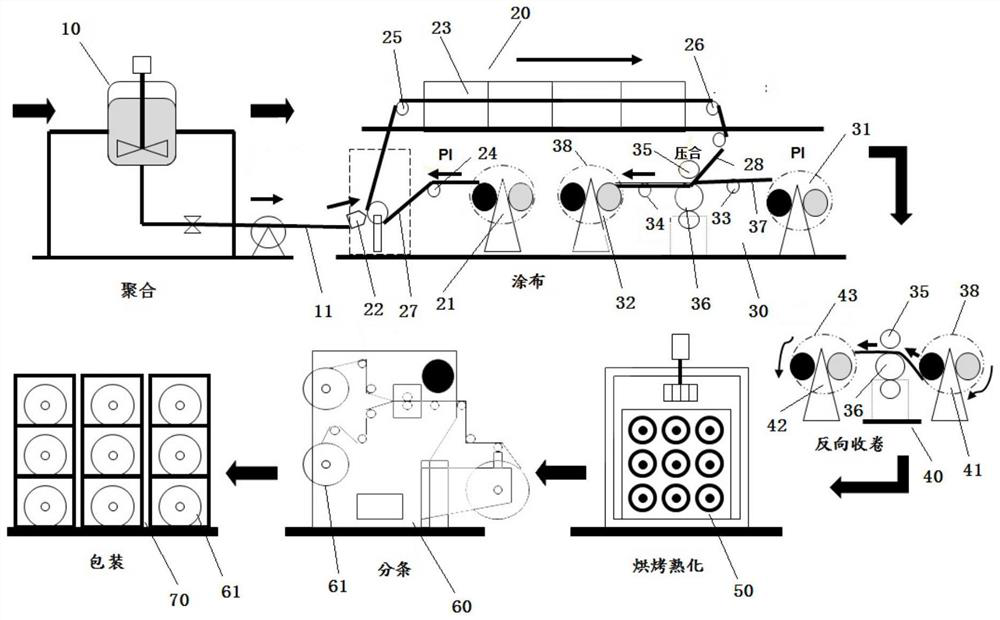

[0049] Step 1: Mix the epoxy resin and curing agent uniformly in the polymerization device 10 and polymerize it for later use, and debug the coating machine at the same time, and the coating machine includes a coating unit 20, a winding unit 30, and a reverse winding unit 40 , baking unit 50 and strip unit 60;

[0050] Step 2: Coating: adjust the tension of the coating unit 20 everywhere, and apply the polymerized epoxy resin 11 evenly on the first polyimide film 27 under low tension conditions by using the coating unit 20 , to obtain the second polyimide film 28;

[0051] The process parameters during coating are as follows: the unwinding speed of the first unwinding assembly 21 is 15m / min, the pressure is 2kg, the tension at the first tension arm 24 is 40N, and the tension at the second tension arm 25 The tension at the tension arm 26 is 45N, and the tension at the third tension arm 26 is 40N; the o...

Embodiment 2

[0059] Embodiment 2: Composite film adopts following method to make:

[0060] Step 1: Mix the epoxy resin and curing agent uniformly in the polymerization device 10 and polymerize it for later use, and debug the coating machine at the same time, and the coating machine includes a coating unit 20, a winding unit 30, and a reverse winding unit 40 , baking unit 50 and strip unit 60;

[0061] Step 2: Coating: adjust the tension of the coating unit 20 everywhere, and apply the polymerized epoxy resin 11 evenly on the first polyimide film 27 under low tension conditions by using the coating unit 20 , to obtain the second polyimide film 28;

[0062] The process parameters during coating are as follows: the unwinding speed of the first unwinding assembly 21 is 15m / min, the pressure is 2kg, the tension at the first tension arm 24 is 30N, and the tension at the second tension arm 25 The tension at the tension arm 26 is 40N, and the tension at the third tension arm 26 is 35N; the oven ...

Embodiment 3

[0070] Embodiment 3: Composite membrane adopts following method to make:

[0071] Step 1: Mix the epoxy resin and curing agent uniformly in the polymerization device 10 and polymerize it for later use, and debug the coating machine at the same time, and the coating machine includes a coating unit 20, a winding unit 30, and a reverse winding unit 40 , baking unit 50 and strip unit 60;

[0072] Step 2: Coating: adjust the tension of the coating unit 20 everywhere, and apply the polymerized epoxy resin 11 evenly on the first polyimide film 27 under low tension conditions by using the coating unit 20 , to obtain the second polyimide film 28;

[0073] The process parameters during coating are as follows: the unwinding speed of the first unwinding assembly 21 is 15m / min, the pressure is 2kg, the tension at the first tension arm 24 is 50N, and the tension at the second tension arm 25 The tension at the tension arm 26 is 50N, and the tension at the third tension arm 26 is 45N; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com