Source plate applied to photovoltaic plate

A technology of photoelectric boards and connecting boards, which is applied to parts of color TVs, parts of TV systems, TVs, etc., can solve the problems of increasing product costs, high assembly costs, and high costs, reducing the probability of board warping and reducing The total cost of the product and the effect of mitigating mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

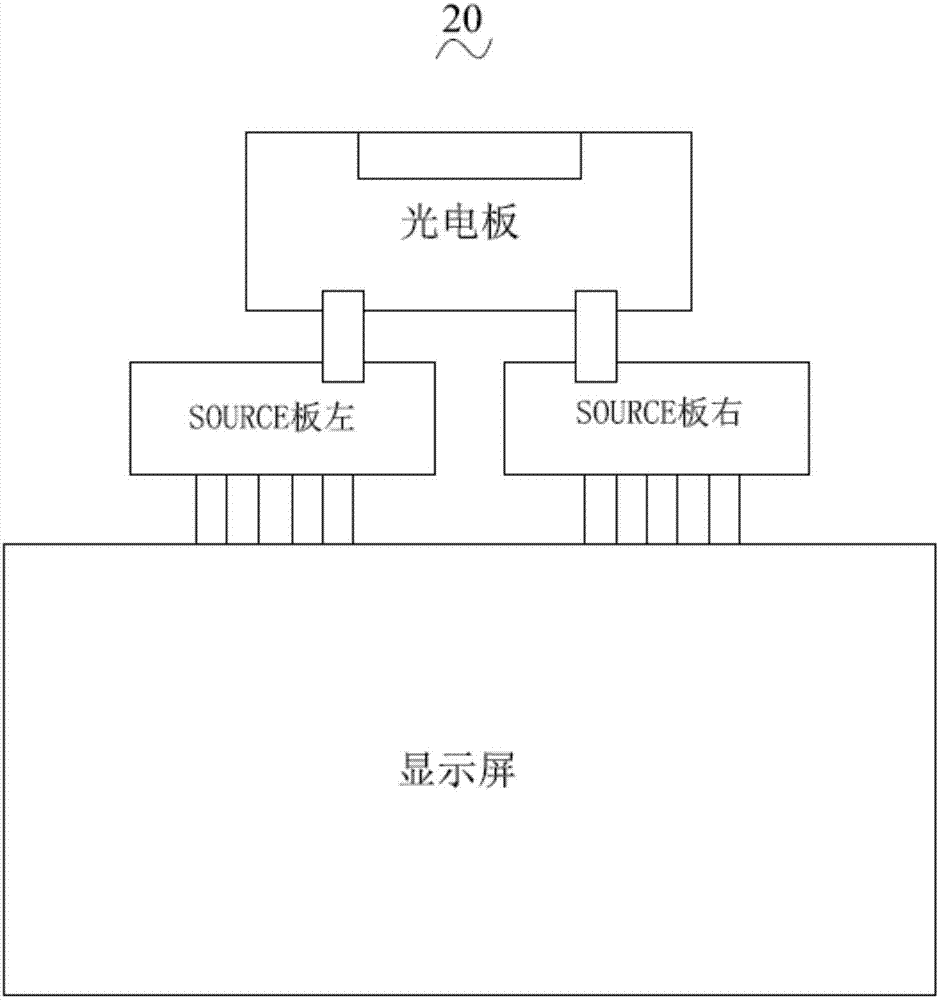

[0034] see figure 1 20 is the connection structure of the Source board of a traditional LCD TV. The left side of the Source board and the right side of the Source board are respectively connected to the photoelectric board, and the left side of the Source board and the right side of the Source board are also connected to the display screen respectively. As a result, each Source board is managed separately, which wastes time and manpower. The left side of the Source board and the Source board need to be installed separately, which increases the difficulty, time and energy of assembly. Each of the left and right panels of Source is individually printed, punched, and assembled, which is not only cumbersome, but also time-consuming, labor-intensive and costly.

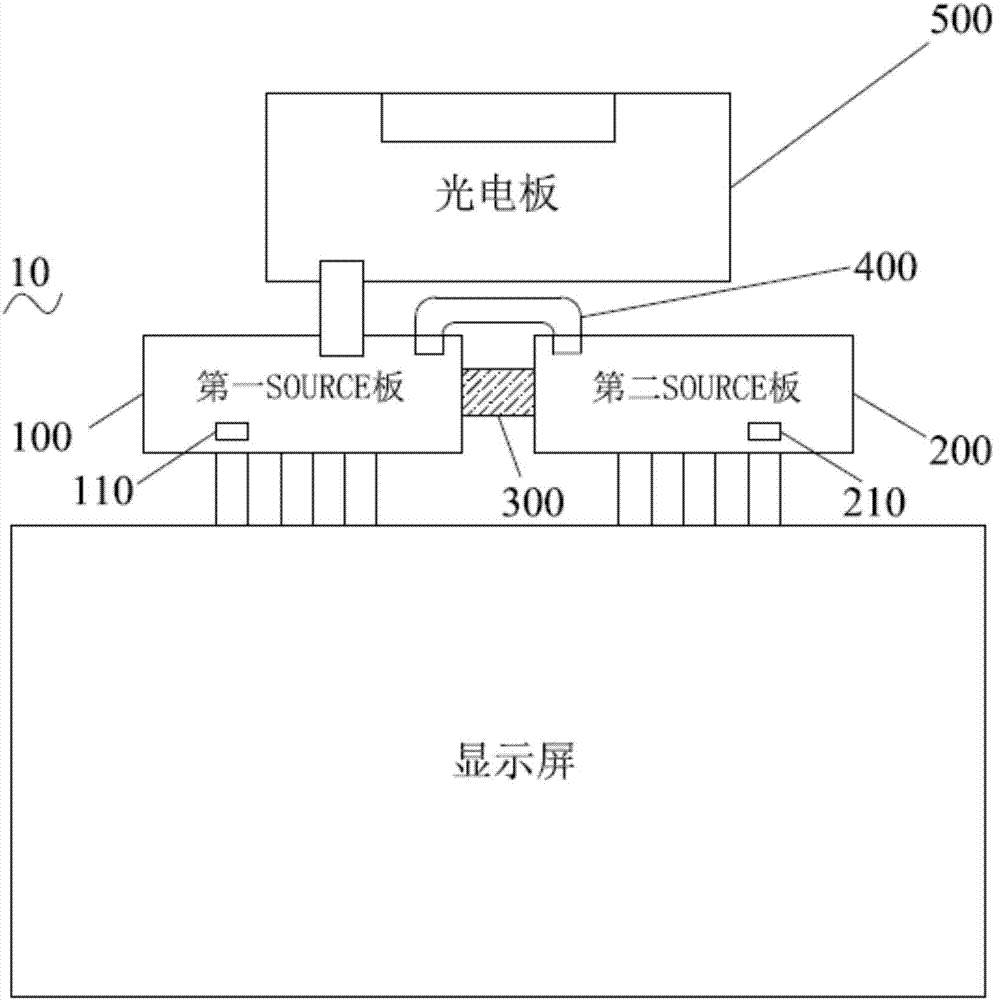

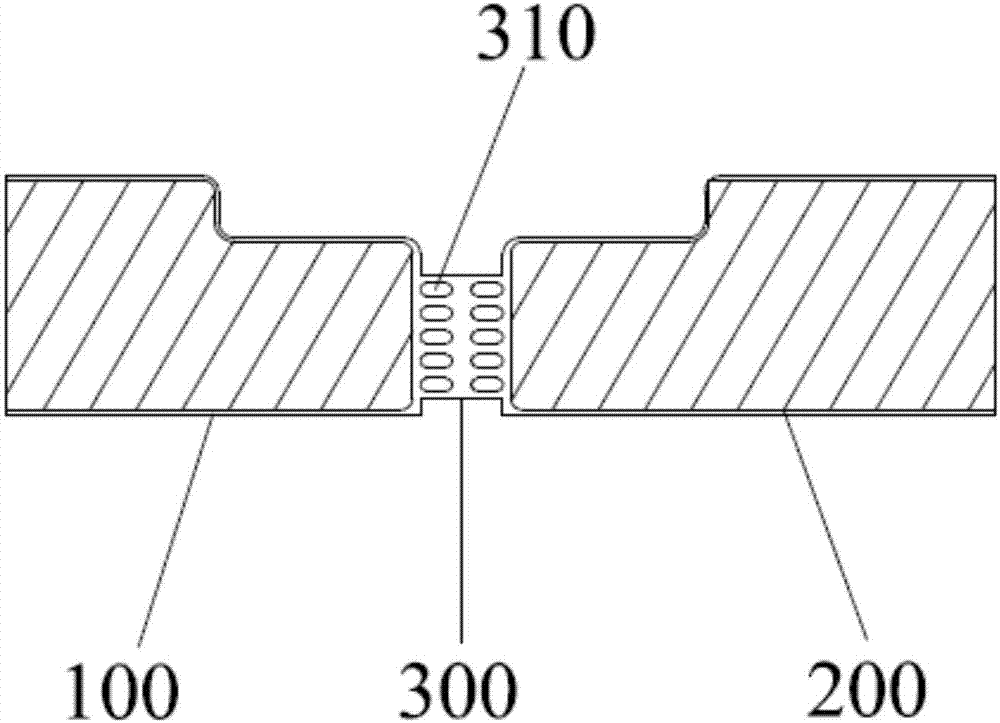

[0035] Based on the shortcomings of the above products, the Source board of the present invention is designed. see figure 2 , providing a Source board applied to photovoltaic panels, including: a Source board body 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com