Doped high-nickel ternary precursor and preparation method thereof

A precursor and doping-type technology, applied in chemical instruments and methods, electrical components, nickel compounds, etc., can solve the problem of not being able to obtain high-nickel ternary materials, and achieve the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

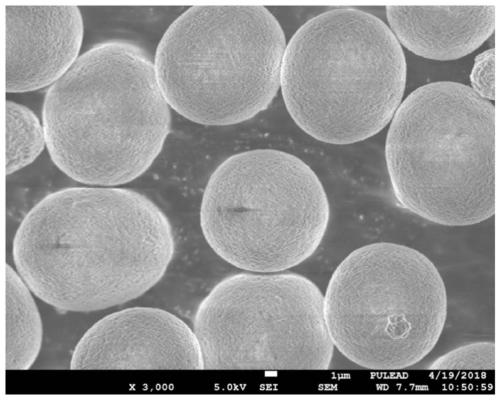

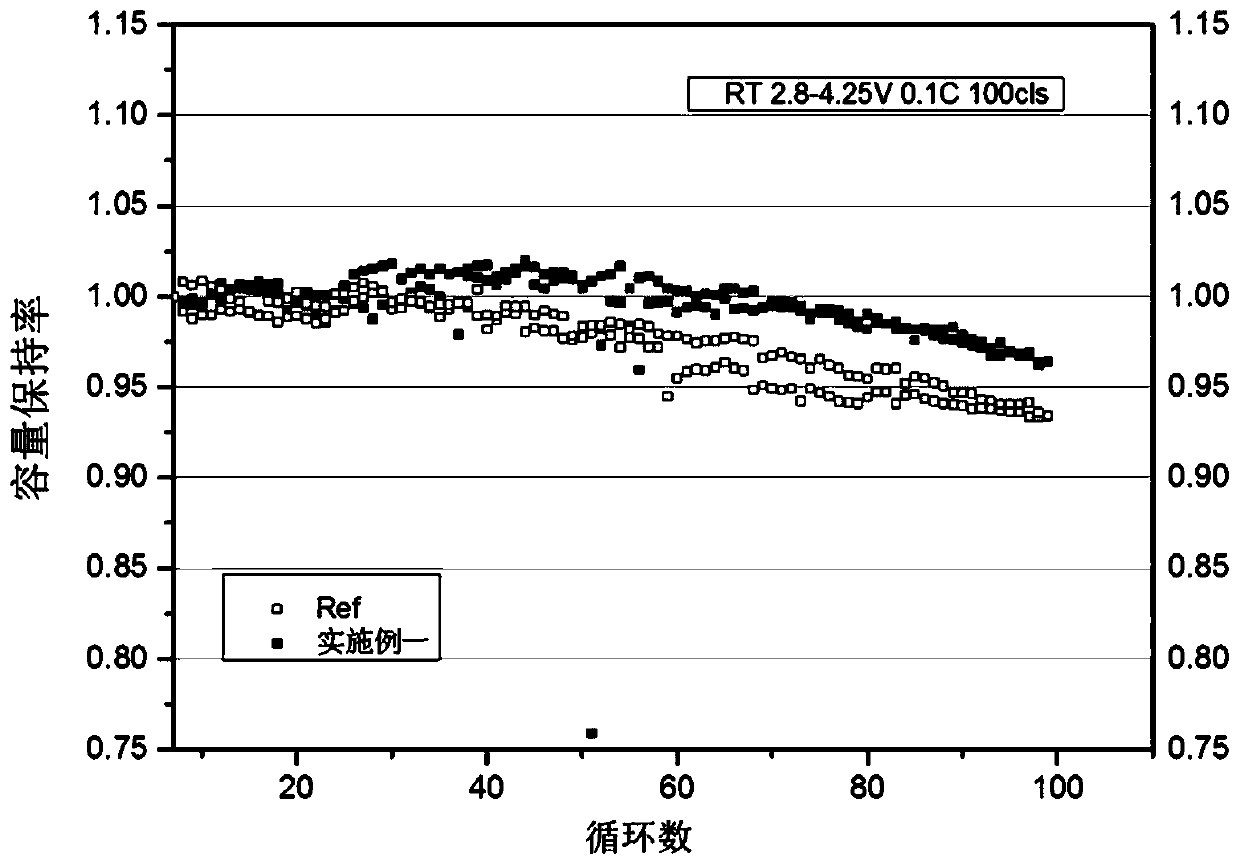

[0031] This embodiment provides a zirconium-doped high-nickel ternary precursor and its preparation method, the steps are as follows:

[0032] Prepare 2mol / L nickel sulfate, cobalt sulfate, manganese sulfate mixed solution, Ni:Co:Mn ratio is 0.82:0.12:0.06, prepare 3mol / L ammonia water, prepare 4mol / L sodium hydroxide solution, mix these three kinds The solutions are injected into the stirred reactor at the same time, and the injection speed of the three solutions is adjusted so that the molar ratio of the three solutions is controlled at ammonia water / total metal salt=0.3, sodium hydroxide / total metal salt=2.0, and the reaction is controlled. The temperature is 50°C, the pH value is 11.8, and the particle size is continuously monitored during the process. When the particle size D50 grows to 7 μm, the reaction salt solution is replaced with a 2mol / L mixed solution of nickel sulfate, cobalt sulfate, manganese sulfate, and zirconium sulfate. The ratio of Ni:Co:Mn is 0.82:0.12:0....

Embodiment 2

[0036] This embodiment provides a molybdenum-doped high-nickel ternary precursor and its preparation method, the steps are as follows:

[0037] Prepare nickel sulfate, cobalt sulfate, manganese sulfate mixed solution of 2mol / L, Ni:Co:Mn ratio is 0.83:0.11:0.06, prepare the ammoniacal liquor of 3mol / L, prepare the sodium hydroxide solution of 4mol / L, these three kinds The solutions are injected into the stirred reactor at the same time, and the injection speed of the three solutions is adjusted so that the molar ratio of the three solutions is controlled at ammonia water / total metal salt=0.5, sodium hydroxide / total metal salt=2.2, and the reaction is controlled. The temperature is 50°C, the pH value is 11.7, and the particle size is continuously monitored during the process. When the particle size D50 grows to 6 μm, the reaction salt solution is replaced with a 2mol / L mixed solution of nickel sulfate, cobalt sulfate, manganese sulfate, and molybdenum sulfate. The ratio of Ni:Co...

Embodiment 3

[0041] This embodiment provides a cerium-doped high-nickel ternary precursor and its preparation method, the steps are as follows:

[0042] Prepare nickel sulfate, cobalt sulfate, manganese sulfate mixed solution of 0.5mol / L, Ni:Co:Mn ratio is 0.88:0.06:0.06, the ammoniacal liquor of preparation 5.2mol / L, the sodium hydroxide solution of preparation 4mol / L, this Three kinds of solutions are respectively co-currently injected into the reactor with stirring, and the injection speeds of the three kinds of solutions are adjusted so that the mol ratio of the three kinds of solutions is controlled at ammonia water / total metal salts=0.8, sodium hydroxide / total metal salts=2.4, Control the reaction temperature to 40°C, pH value to 11.8, and continuously monitor the particle size during the process. When the particle size D50 grows to 8 μm, replace the reaction salt solution with 0.5mol / L nickel sulfate, cobalt sulfate, manganese sulfate, and cerium sulfate In the mixed solution, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com