Carbon-hydrogen refrigerant for substituting R22

A technology for hydrocarbon refrigerants and refrigerants, which can be applied in heat exchange materials, container discharge methods, and equipment loaded into pressure vessels. The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Propane accounting for 80% of the total mass and isobutane accounting for 20% of the total mass are mixed to form a hydrocarbon refrigerant replacing R22.

Embodiment 2

[0031] Propane accounting for 84% of the total mass and isobutane accounting for 16% of the total mass are mixed to form a hydrocarbon refrigerant replacing R22.

Embodiment 3

[0033] Propane accounting for 89% of the total mass and isobutane accounting for 11% of the total mass are mixed to form a hydrocarbon refrigerant replacing R22.

[0034] The above-mentioned refrigerant adopts the method and device described in a patented technology (named: a refrigerant tank of less than 1000 ml, patent number: ZL200610096857.3) previously authorized by the applicant of this case to carry out the canning and discharge of the refrigerant .

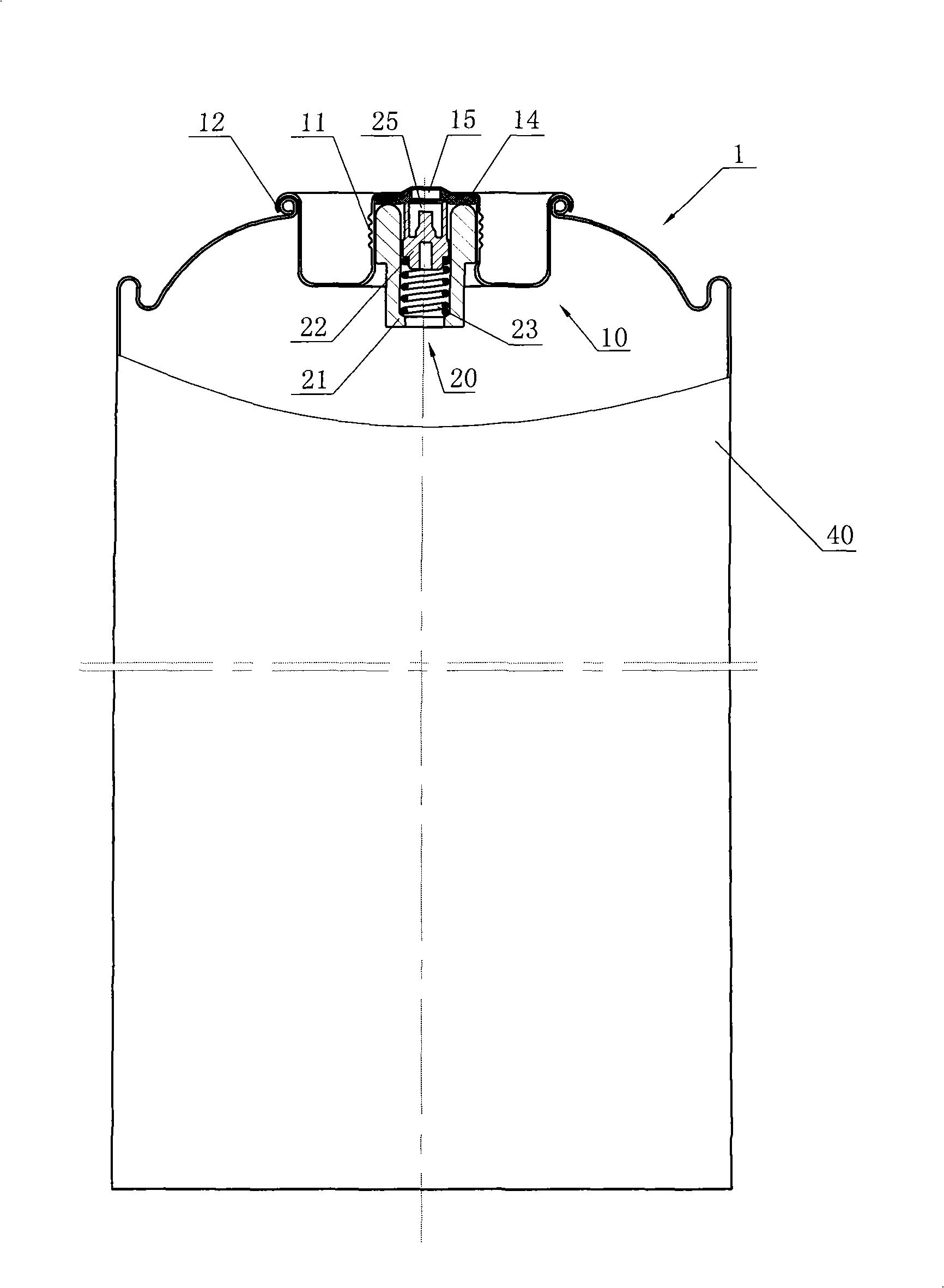

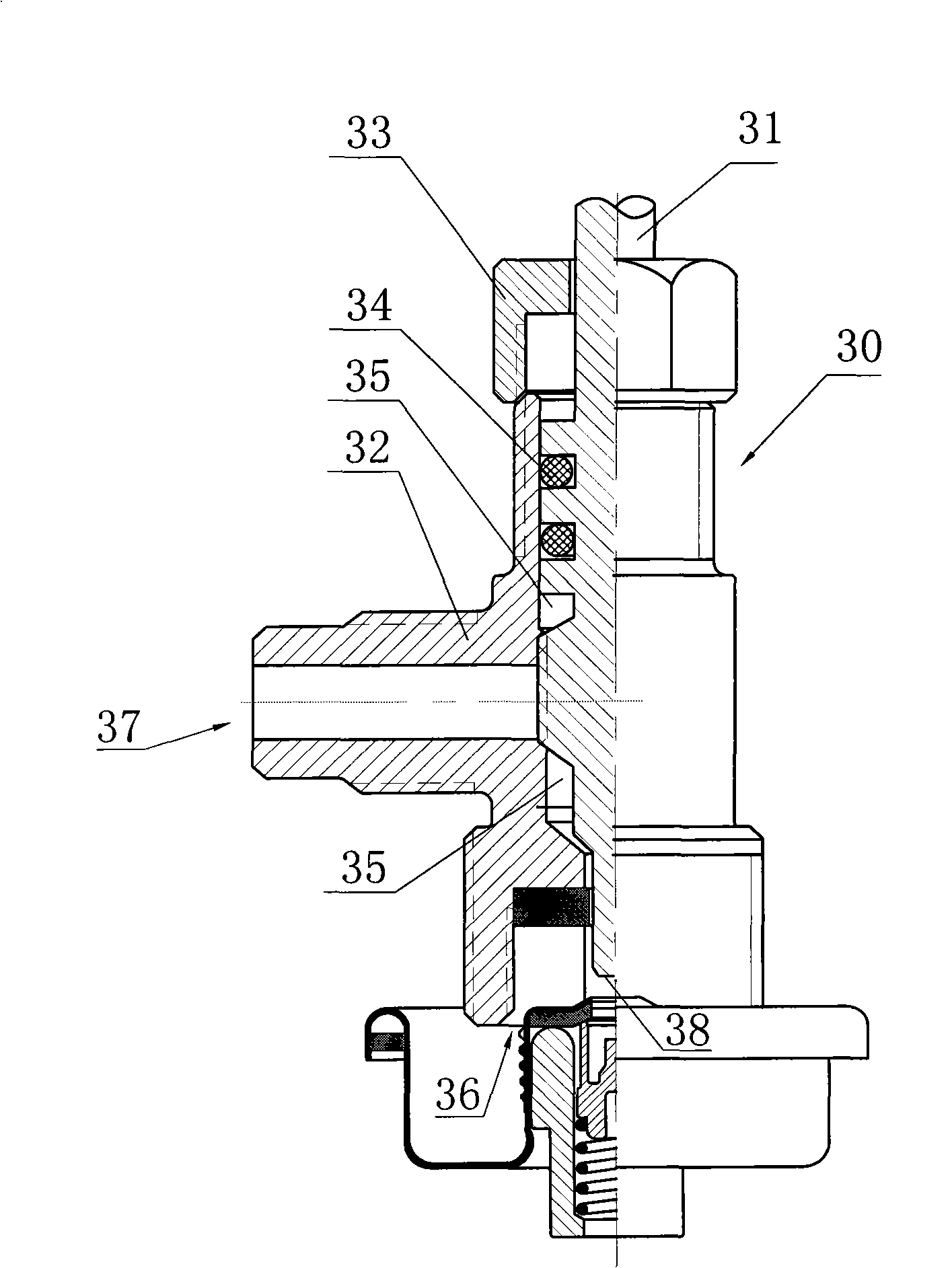

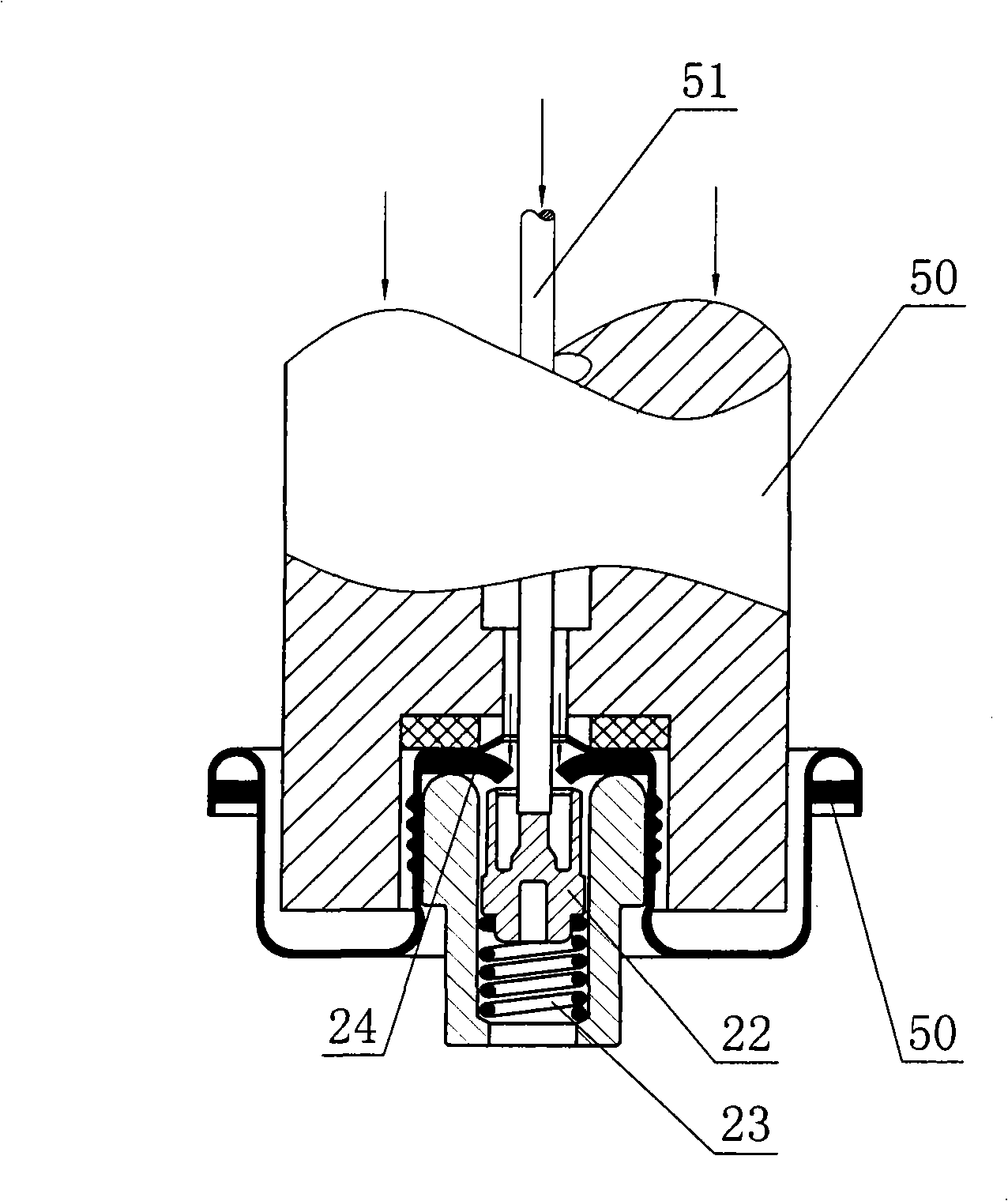

[0035] A special refrigerant tank is used in this patented technology, its structure is as follows figure 1 As shown, it consists of a tank body 40 and a cover 10. A gasket 14 is placed in a cylindrical boss 11 at the center of the cover 10, and a threaded aerosol valve is placed in the boss. This momentary threaded aerosol valve is made up of valve seat 21, valve core 22, and stage clip 23, stage clip 23 is placed in the inner hole 25 of valve seat, valve core 22 is connected on the free end of stage clip 23 upper side, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com