Warehousing system capable of automatically processing and carrying out orders and warehousing method thereof

A warehousing system and automatic processing technology, applied in data processing applications, instruments, manipulators, etc., can solve problems affecting warehouse space utilization, high energy consumption in system operation, height design restrictions, etc., to achieve a simple and easy implementation process, reduce The effect of high operating energy consumption and space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solutions of the present invention will be further specifically described below through the embodiments of the present invention and in conjunction with the accompanying drawings.

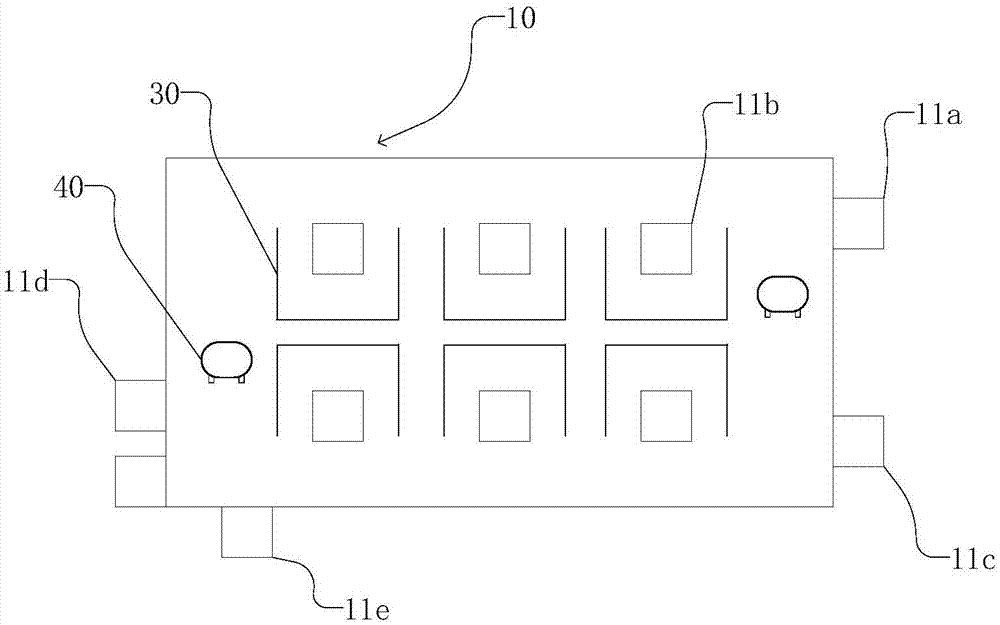

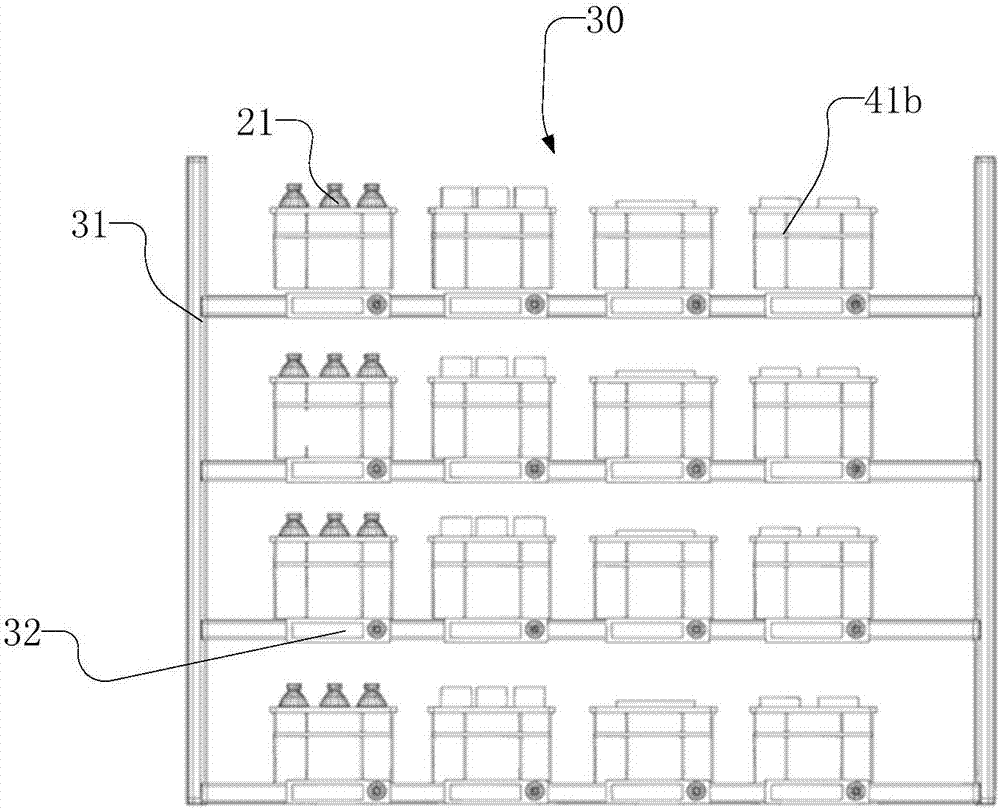

[0056] The present invention proposes a storage system for automatically processing and fulfilling orders. The storage system is located in the warehouse site. The storage system includes:

[0057] A number of stock shelves for storing stock goods in the warehouse;

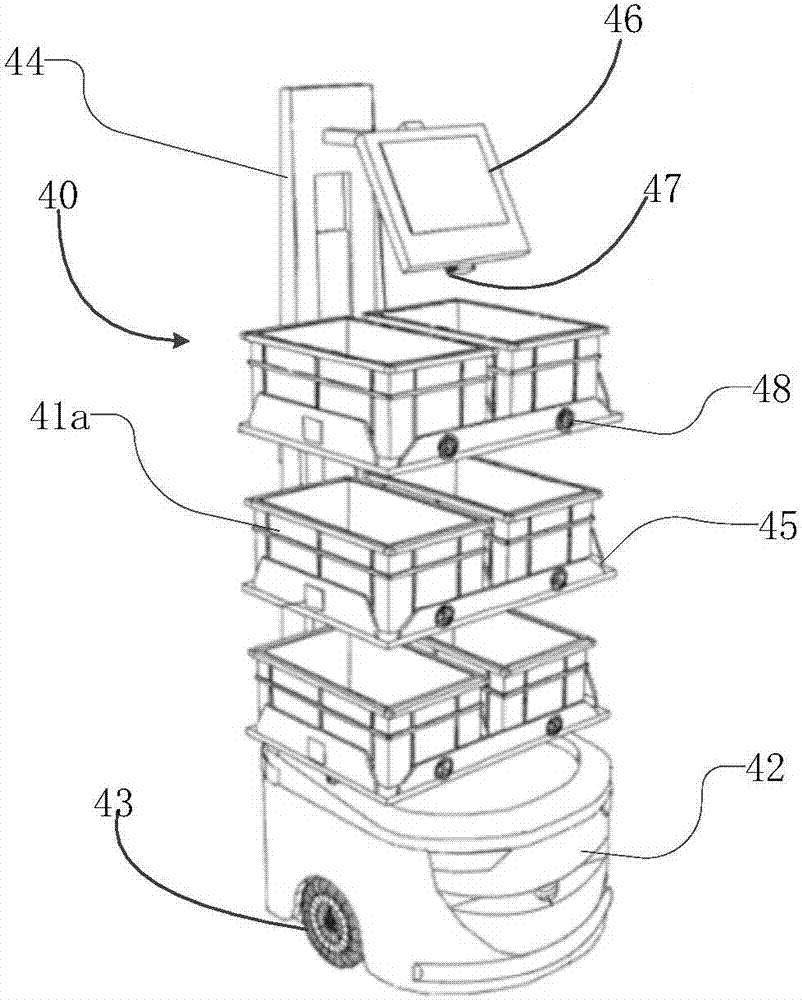

[0058] Several mobile order carts are used to carry goods in and out of the warehouse. Each mobile order cart carries and moves in the warehouse site according to the bound order and docks with operators or robots until the mobile order cart binds all the mobile order carts. The inventory closing operation of the order is completed;

[0059] Several operating stations are distributed near the inventory shelves and are used to carry warehousing operations. The operators or robots at the operating stations perform i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com