Transplant strengthening structure of multi-linkage printed circuit board

A printed circuit board and strengthening structure technology, which is applied in the structural connection of printed circuits, printed circuit components, etc., can solve problems such as board warpage or breakage, reduce board warping, improve bonding, and transplant firm and stable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

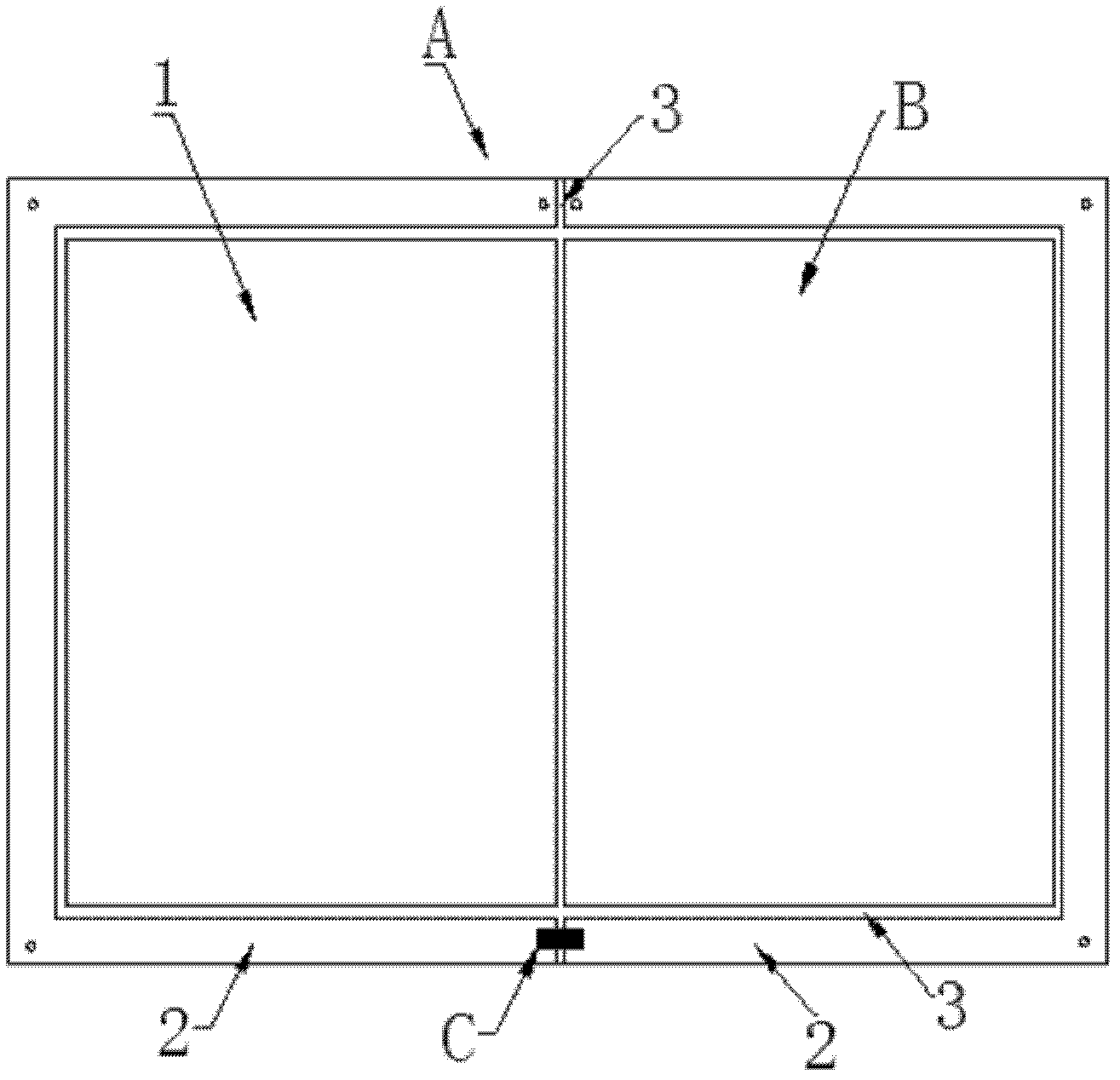

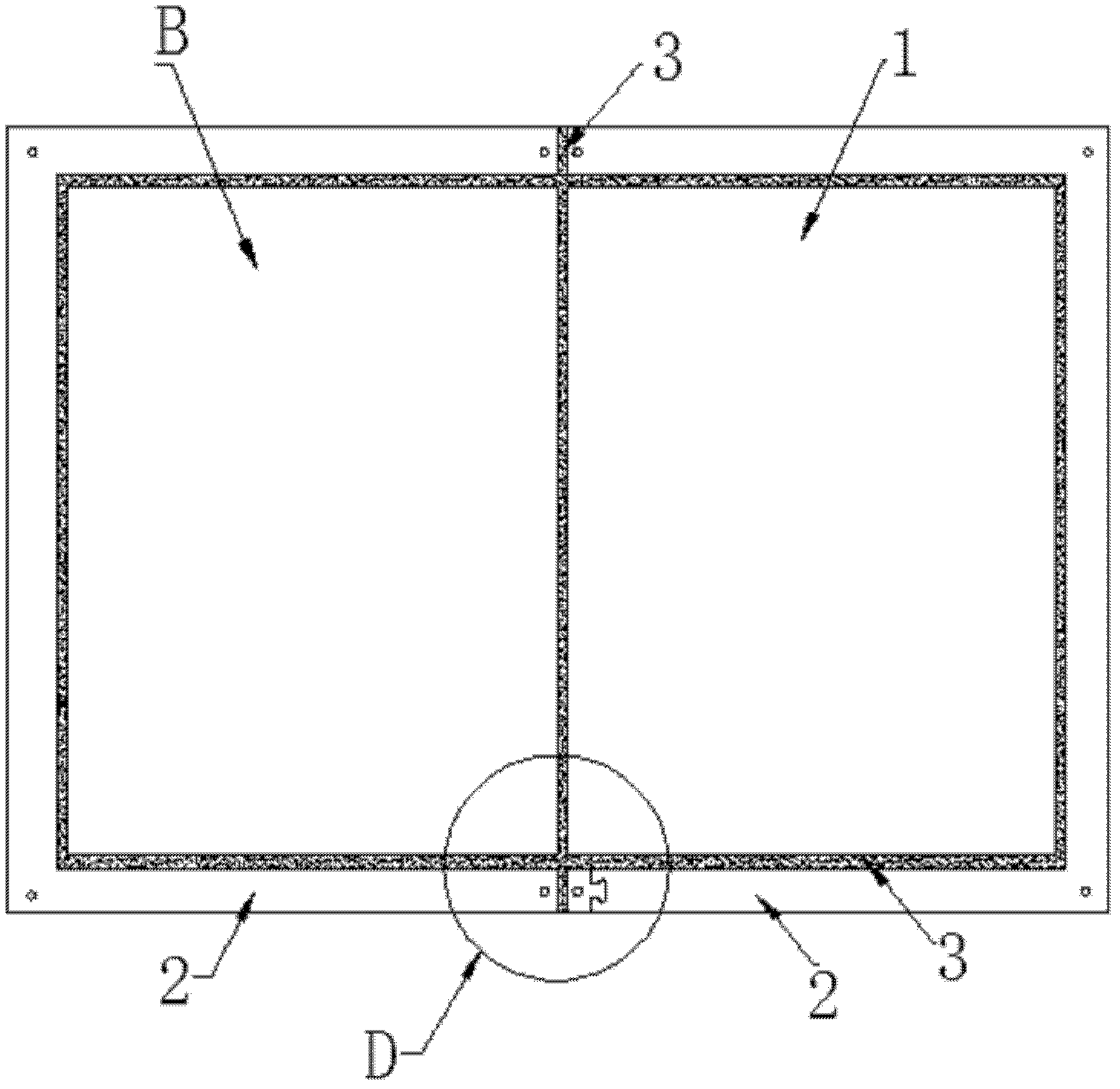

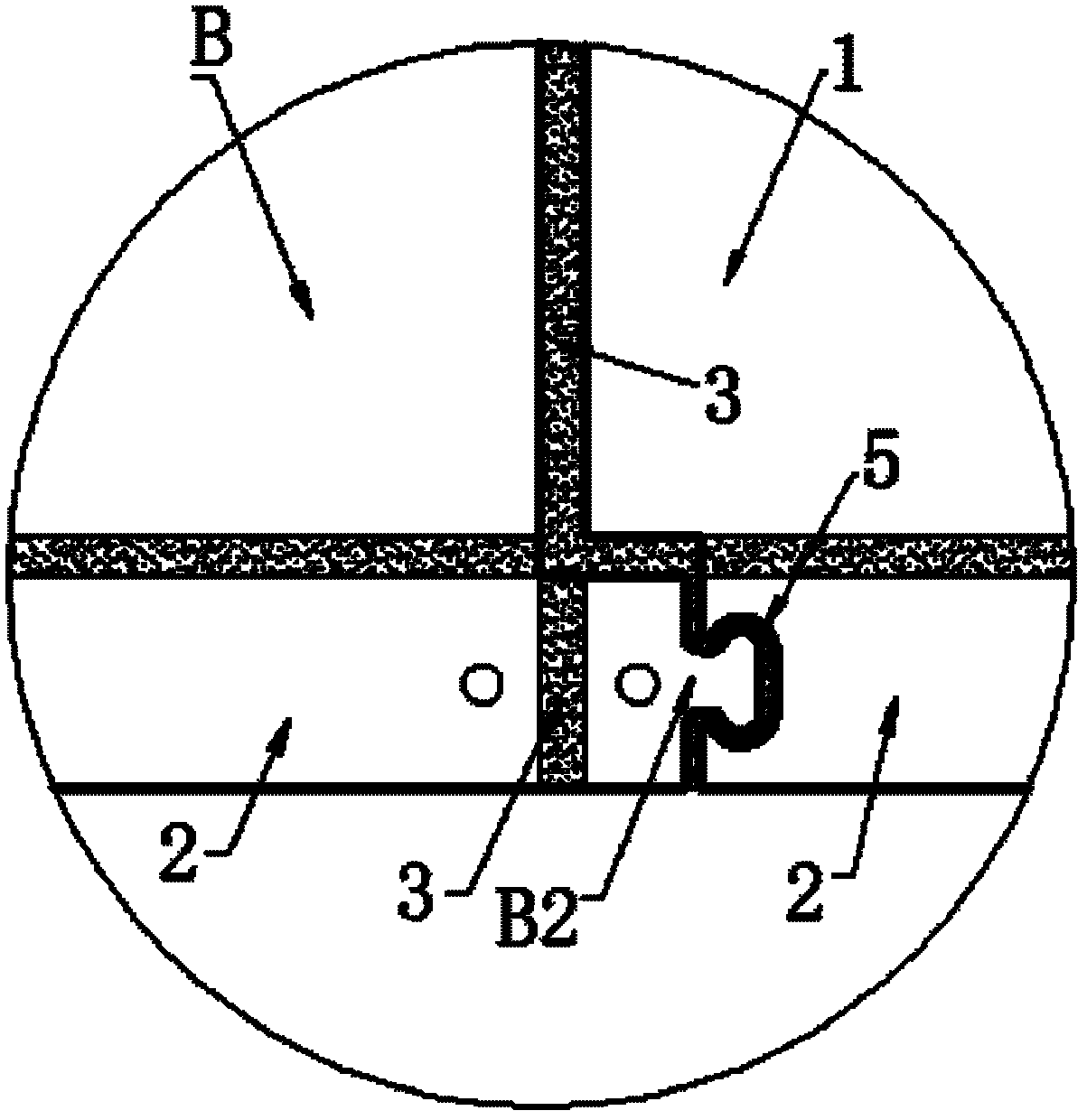

[0014] Embodiment: A transplantation strengthening structure of a multi-connected printed circuit board, the multi-connected printed circuit board A has several sub-circuit boards 1 and board frames 2, between the sub-circuit boards and the board frames, adjacent sub-circuit boards There is a breaking line 3 for breaking between and between adjacent board frames, and there is at least one grafting area on the multi-connected printed circuit board, and the grafting area is formed after the unqualified sub-circuit board is removed, A qualified spare sub-circuit board B is arranged in the transplantation area, the spare sub-circuit board has a board frame 2, and there is a breaking line 3 for breaking between the spare sub-circuit board and its board frame, and at least one connection Groove C, the two ends of the connecting groove are respectively located in the adjacent plate frames 2 and the connecting groove passes through the breaking line between the plate frames, the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com