Method for grinding back surface of DBC substrate

A back grinding and substrate technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problem of uneven surface height of DBC substrates, improve surface appearance, maintain roughness, and reduce board surface warpage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

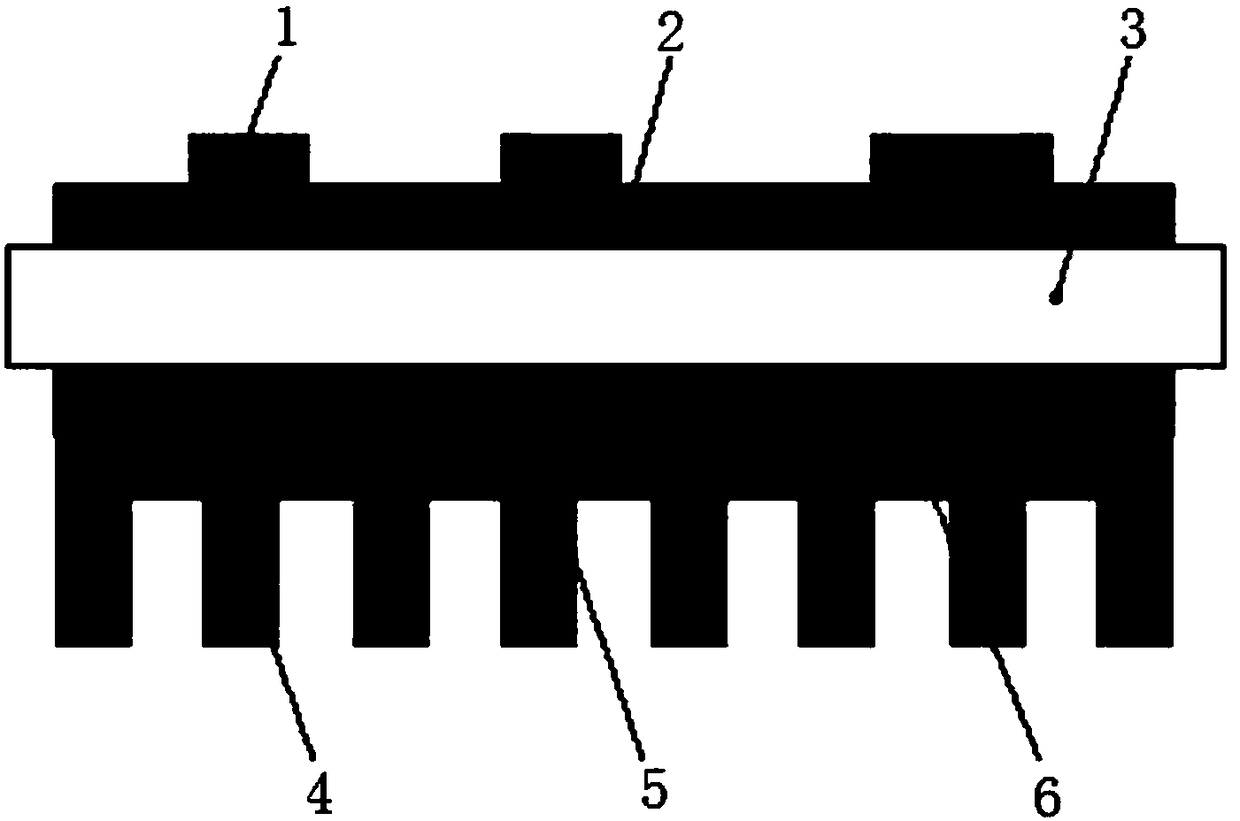

[0022] Below in conjunction with accompanying drawing, the present invention will be further described.

[0023] In order to solve the problem that the unevenness of the back of the DBC substrate affects the bonding with the radiator, the invention achieves the purpose of leveling the back of the DBC substrate by adding a mechanical grinding process.

[0024] Specific steps are as follows:

[0025] Step 1. Set up a hard brush roller, and the back of the substrate is ground once by the hard brush roller;

[0026] (1) The speed of the hard brush roller is set to 1.0-2.0m / min;

[0027] (2) The amount of grinding on the back copper surface is controlled within the range of 10um to 30um;

[0028] (3) Hard brush roller mesh: 400~900#; current: 0.4~0.9A;

[0029] Step 2. Set three soft brush rollers, and polish the back of the substrate three times with soft brush rollers;

[0030] (1) The speed of the soft brush roller is set to 1.0-2.0m / min;

[0031] (2) Mesh of soft brush rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com