A kind of manufacturing method of asymmetrical multi-plate nested collage type mixed pressure plate

A production method and asymmetric technology, applied in the direction of multilayer circuit manufacturing, circuit substrate materials, printed circuit components, etc., can solve the production cost of warped boards, reduce the production cost of circuit boards and other problems, and achieve the reduction of warped boards. Warping, increasing the amount of signal transmission, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

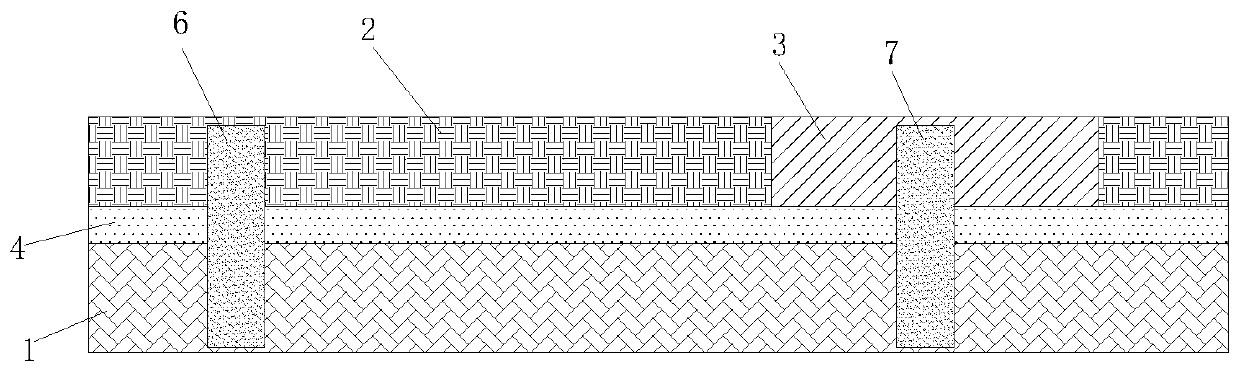

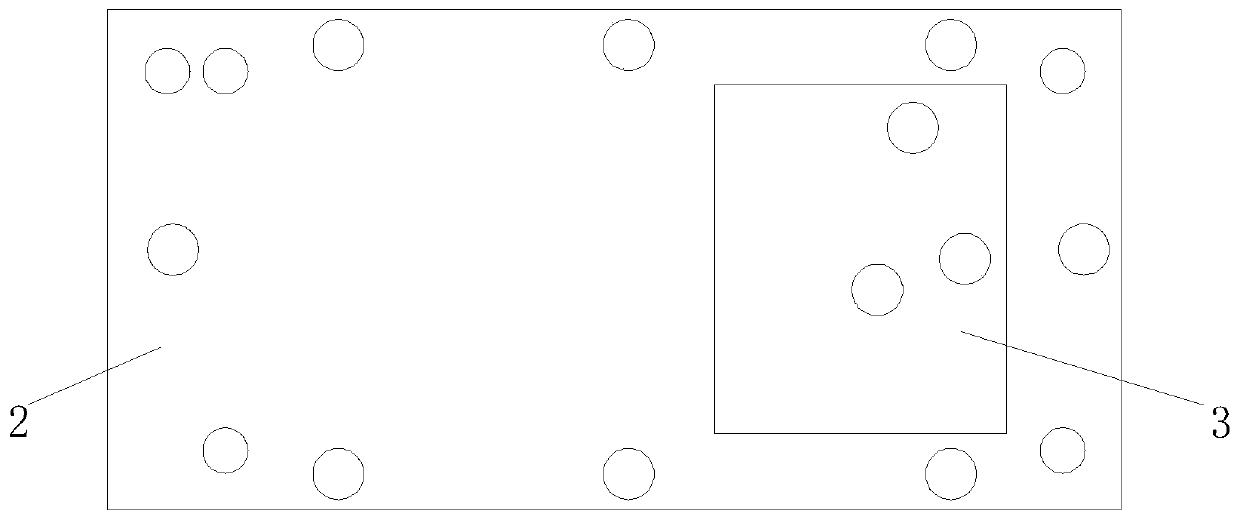

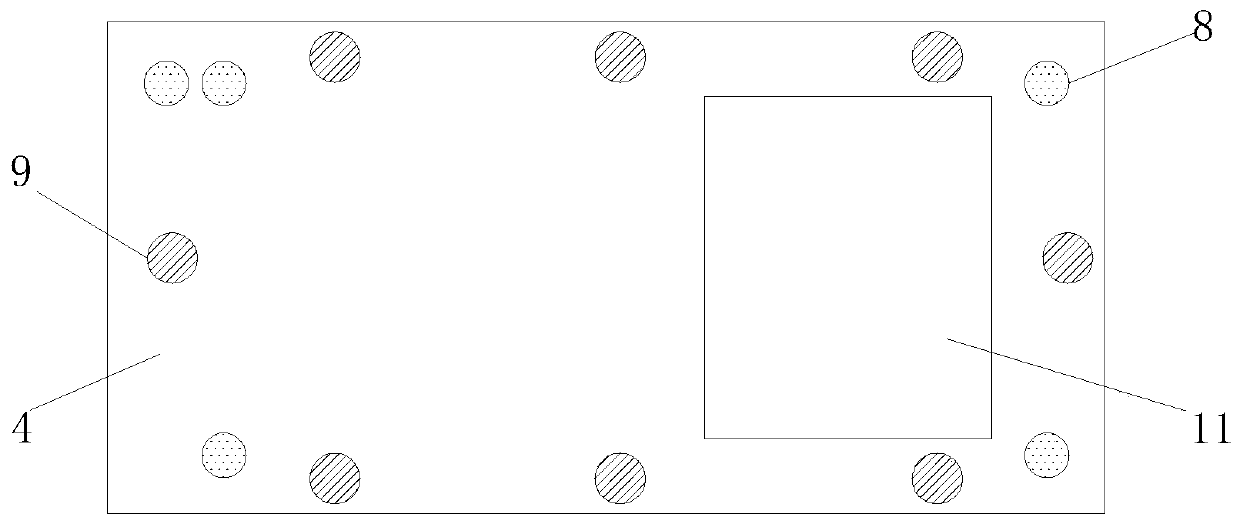

[0028] Such as Figure 1 to Figure 4 As shown, this embodiment provides a method for manufacturing an asymmetrical multi-plate nested collage type mixed pressure panel. The mixed pressure plate includes plate one 1, plate two 2 and plate three 3 made of different materials. The manufacturing method Specific steps are as follows:

[0029] (1) Make a production board with an inner circuit:

[0030] According to the existing technology, through cutting → drilling → making inner layer circuit → cutting → window opening → pre-riveting → positioning → pressing, the three kinds of plates are pressed together to make a production board with inner layer circuit; as follows:

[0031] a. Cutting: According to the panel size 457mm×544mm, the first sheet 1, the second sheet 2, the third sheet 3, the PP sheet 14 and the PP sheet 2 are cut out;

[0032] b. Drilling: use the board edge tool hole positioning, and drill 5 graphic positioning holes 8 (including error prevention) at the corres...

Embodiment 2

[0048] This embodiment provides a method for manufacturing an asymmetrical multi-plate nested collage-type mixed laminated board. This method is basically the same as that of Embodiment 1, except that step (1) manufactures a production board with an inner circuit. Specifically as follows:

[0049] a. Cutting: According to the panel size 457mm×544mm, the plate 1, plate 2, plate 3, PP sheet 1 and PP sheet 2 are produced;

[0050] b. Drilling: Positioning with tool holes on the edge of the board, first drill out the pattern positioning holes at the corresponding positions of plate 1, plate 2, plate 3, PP sheet 1 and PP sheet 2, and then use the pattern positioning holes to position and drill out the rivets Positioning holes and pin positioning holes;

[0051] c. Making the inner layer circuit (negative film process): According to the design requirements, the three kinds of boards are positioned with different pattern positioning holes, produced by a vertical coating machine, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com