Method for producing 1,3-dimethyladamantane

一种二甲基金刚烷、制造方法的技术,应用在有机化学方法、化学仪器和方法、异构化制烃等方向,能够解决不是、未知晓、不能再利用氯化铝等问题,达到高收率、降低环境负荷的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

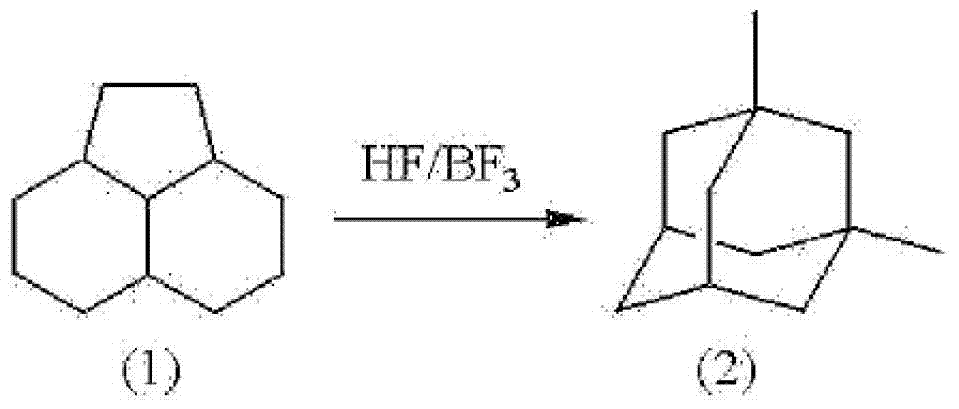

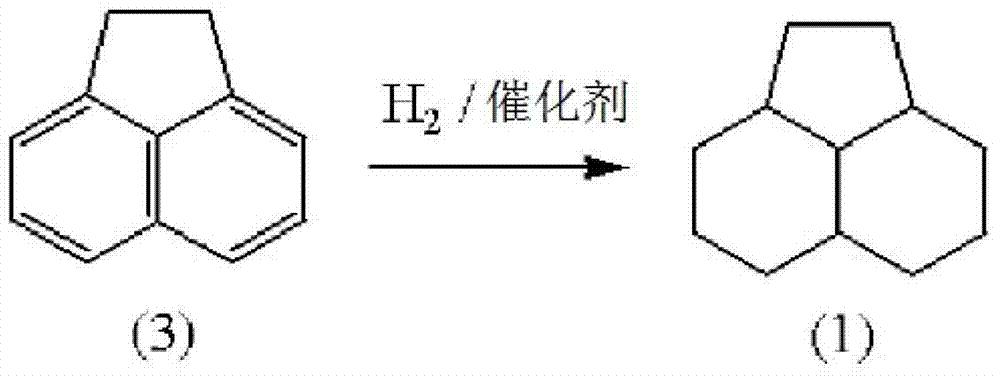

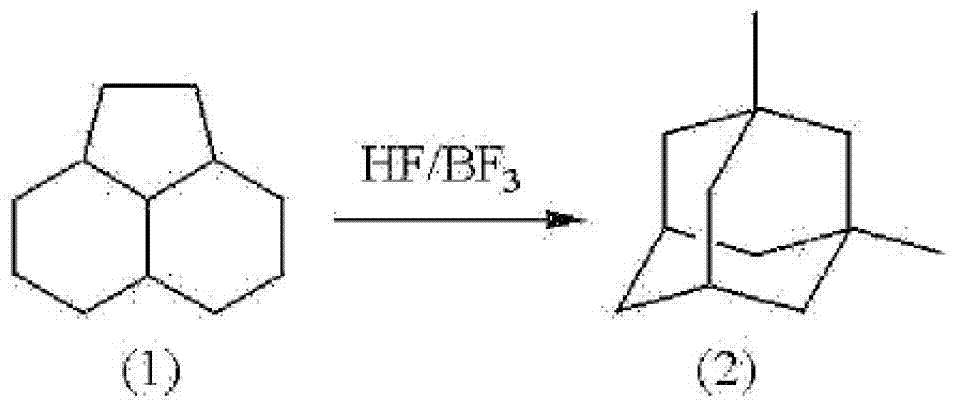

Method used

Image

Examples

Embodiment 1

[0051] The isomerization reaction of PHA was carried out using an autoclave made of Hastelloy with an internal volume of 0.5 L having an electromagnetic stirring device, a heating device, a gas supply port, a liquid supply port, and a reactant discharge port. 50g (2.5 moles) of HF manufactured by Morita Chemical Industry Co., Ltd. and 100 g (0.6 moles) of PHA were added to the reactor, and 16 g (0.24 moles) of BF manufactured by STELLACHEMIFA CORPORATION were supplied. 3 . Next, the temperature was raised to 100° C. by a heating device without adding a solvent, and the mixture was stirred for 4 hours while maintaining the temperature. When the reaction product liquid was sampled, it was found that the yield of 1,3-dimethyladamantane was 77% based on PHA as a raw material. In addition, based on PHA as a raw material, the yield of 1-ethyladamantane as an intermediate was 15%, and no high boiling point compound was observed. Then, by standing and separating into two layers, an ...

Embodiment 2

[0053] Using HF and BF recovered in Example 1 3 , except that, the reaction was carried out under the same conditions, the yield of 1,3-dimethyladamantane was 75%, and no deactivation of the catalyst was observed. In addition, similarly to Example 1, no high boiling point compound was observed.

Embodiment 3

[0055] The isomerization reaction of PHA was carried out using an autoclave made of Hastelloy with an internal volume of 0.5 L having an electromagnetic stirring device, a heating device, a gas supply port, a liquid supply port, and a reactant discharge port. 50g (2.5 moles) of HF manufactured by Morita Chemical Industry Co., Ltd. and 100 g (0.6 moles) of PHA were added to the reactor, and 16 g (0.24 moles) of BF manufactured by STELLACHEMIFA CORPORATION were supplied. 3 . Next, the temperature was raised to 80° C. by a heating device without adding a solvent, and the mixture was stirred for 4 hours while maintaining the temperature. When the reaction product liquid was sampled, it was found that the yield of 1,3-dimethyladamantane was 51% based on PHA as a raw material. In addition, based on PHA as a raw material, the yield of 1-ethyladamantane as an intermediate was 42%, and no high boiling point compound was observed. Then, by standing and separating into two layers, an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rate of recovery | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| rate of recovery | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com