Insulating tree shears

A scissors and tree technology, applied in the field of insulating tree scissors, can solve the problems of scissors breaking, difficult to cut branches, prone to electric shock accidents, etc., so as to avoid electric shock accidents and avoid collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

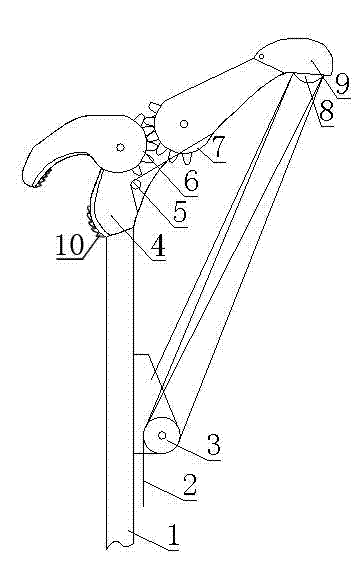

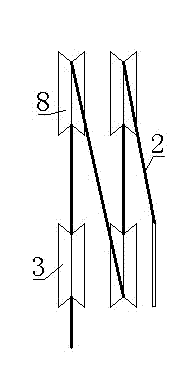

[0019] As shown in the figure, the insulating tree shears include a rod body 1, a lower shear body 4 is arranged on the top of the rod body 1, an upper shear body 6 and a pressure handle 7 are hinged on the lower shear body 4, and the pressure handle 7 and A torsion spring 5 is arranged between the lower shearing bodies 4, and the pressing handle 7 is engaged with the upper shearing body 4 through gear teeth. A moving pulley block 8 is arranged at the end of the pressing handle 7, and a block is arranged on the moving pulley block 8. Cover 9 is provided with fixed pulley block 3 on rod body 1, is provided with stay rope 2 on rod body 1, is provided with two movable pulleys in described movable pulley block 8, is provided with two fixed pulleys in described fixed pulley block 3, described Stay cord 2 passes through a movable pulley successively, a fixed pulley, another movable pulley, and another fixed pulley. Teeth 10 are respectively provided on the upper shear body 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com