Method for preparing cement by modified compound coal ash

A technology of cement preparation and fly ash, which is applied in the field of building materials, can solve the problems of polluted land and water sources, and achieve the effect of reducing the amount of use and improving the early activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Grind the fly ash separately to 400m 2 / kg, 500m 2 / kg, 550m 2 / kg, the three kinds of fly ash were mixed at the ratio of 17%:33%:50% to obtain compound fly ash. Use P·I62.5R cement clinker, after the cement is ground to 300m 2 After adding 20% compound fly ash and adding 1.0% of fly ash mass desulfurization gypsum at the same time, mix and grind until the specific surface area is 400m 2 / kg, to prepare P·O52.5R cement. Its basic properties are shown in Table 1. As can be seen from Table 1, compared with the unmodified front fly ash, adopting the modification provided by the present invention and using method to use as admixture the performance of each age of preparing cement has improved respectively by 21%, 13%, 35%, 20% %, the effect is remarkable.

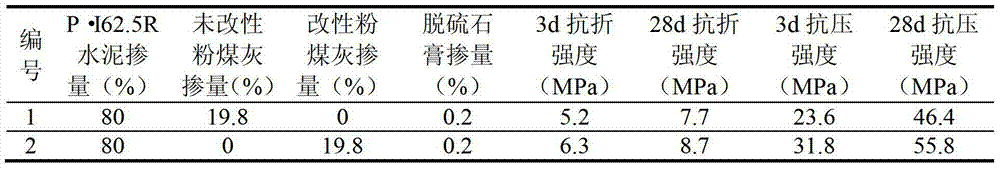

[0016] Table 1 Performance comparison of cement prepared with fly ash before and after modification

[0017]

Embodiment 2

[0019] Grind the fly ash separately to 400m 2 / kg, 500m 2 / kg, 550m 2 / kg, the three kinds of fly ash were mixed at a ratio of 15%:25%:60% to obtain compound fly ash. Use P·I62.5R cement clinker, after the cement is ground to 300m 2 After adding 40% compound fly ash and adding 1.0% of fly ash desulfurization gypsum at the same time, mix and grind until the specific surface area is 450m 2 / kg to prepare P·F42.5R cement. Its basic properties are shown in Table 2. As can be seen from Table 2, compared with the unmodified former fly ash, adopting the modification provided by the present invention and using method to use as admixture the performance of each age of preparing cement has improved respectively by 20%, 16%, 34%, 22% %, the effect is remarkable.

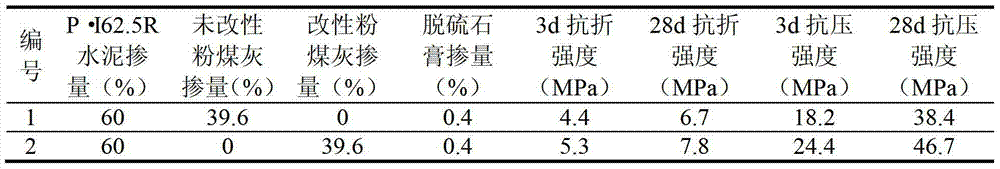

[0020] Table 2 Performance comparison of cement prepared with fly ash before and after modification

[0021]

Embodiment 3

[0023] Grind the fly ash separately to 400m 2 / kg, 500m 2 / kg, 550m 2 / kg, the three kinds of fly ash were mixed at the ratio of 17%:33%:50% to obtain compound fly ash. Use P·I52.5R cement clinker, after the cement is ground to 300m 2 After adding 40% compound fly ash and adding 2% of fly ash mass desulfurization gypsum at the same time, mix and grind until the specific surface area is 450m 2 / kg to prepare P·F42.5R cement. Its basic properties are shown in Table 3. As can be seen from Table 3, compared with the unmodified former fly ash, adopting the modification provided by the present invention and using method to use as admixture use the performance of each age of preparing cement to improve respectively 20%, 21%, 26%, 16%. %, the effect is remarkable.

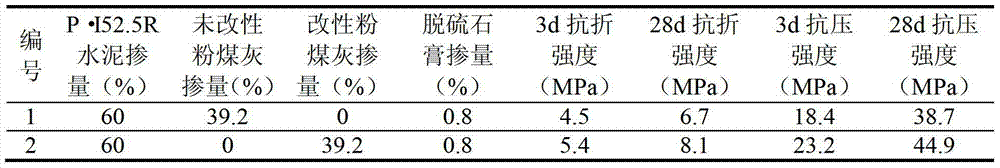

[0024] Table 3 Performance comparison of cement prepared with fly ash before and after modification

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com