Wallboard and mounting method thereof

An installation method and wall panel technology, which is applied to building components, buildings, building structures, etc., can solve the problems of troublesome positioning of wall panels, time-consuming and labor-intensive installation of wall panels, and loose assembly of wall panels, so as to achieve easy and simplified installation. Installation process, effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

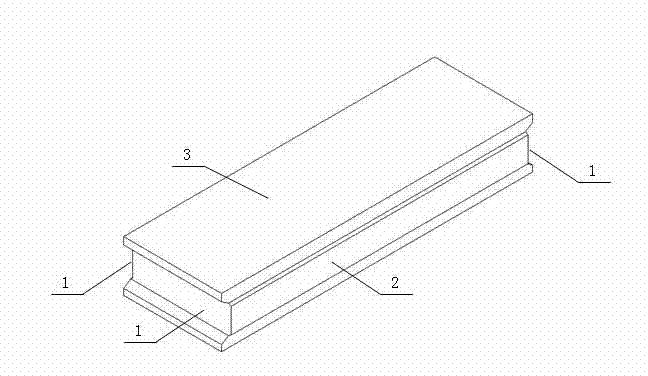

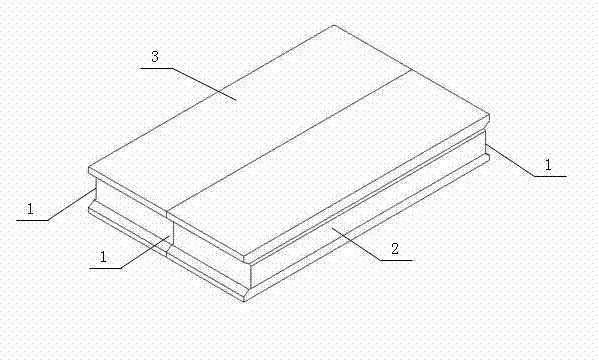

[0035] a wall panel such as figure 1 As shown, its large surface 3 is rectangular in shape, and among the four sides around the large surface, a group of opposite sides are respectively provided with grooves 1 and protrusions 2, and the grooves 1 and protrusions 2 match each other , can be tightly fitted, and grooves 1 are provided on the other set of opposite sides. The groove 1 and the protruding part 2 can be fitted between two wallboards, such as figure 2 shown.

[0036] As a preferred manner, the wallboard is a lightweight wallboard with a shell / core structure. Foam or porous material is used as the core material.

[0037] As a preferred manner, the large surface of the wallboard is flat.

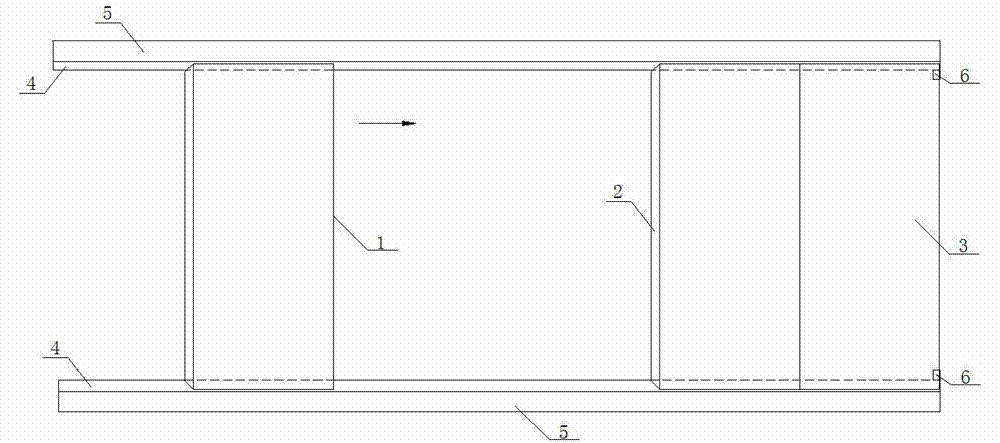

[0038] The installation of the wall panels can be done using image 3 The method shown: First, respectively set fixing strips 5 with protrusions 4 between the upper and lower floors of the pre-installation floor, the fixing strips 5 are horizontally fixed on the floor, and the pr...

Embodiment 2

[0041] A wallboard, its large surface 3 is rectangular in shape, and among the four sides around the large surface, a group of opposite sides are respectively provided with a groove 1 and a protrusion 2, and the groove 1 and the protrusion 2 They are matched with each other and can be tightly fitted, and the other set of opposite sides are provided with protrusions 2 . Two wallboards can be fitted with each other through the groove 1 and the protruding part 2 .

[0042] As a preferred manner, the wallboard is a lightweight wallboard with a shell / core structure. Foam or porous material is used as the core material.

[0043] As a preferred manner, the large surface of the wallboard is flat.

[0044]The installation method of the wallboard is similar to the installation method described in Embodiment 1: first, a fixing strip is provided on the two opposite sides of the pre-installation position, and the fixing strip is provided with a protruding part 2 that matches the wallboar...

Embodiment 3

[0046] A wallboard, its large surface 3 is rectangular in shape, and among the four sides around the large surface, a group of opposite sides are respectively provided with a groove 1 and a protrusion 2, and the groove 1 and the protrusion 2 They are matched with each other and can be tightly fitted, and grooves 1 and protrusions 2 are respectively provided on the other set of opposite sides. Two wallboards can be fitted with each other through the groove 1 and the protruding part 2 .

[0047] As a preferred manner, the described is a lightweight wallboard with a board shell / board core structure. Foam is used as the core material.

[0048] As a preferred manner, the large surface of the wallboard is flat.

[0049] The installation method of the wallboard is as follows: firstly set a fixing strip on two opposite sides of the pre-installation position, one of the fixing strips is provided with a depression 7 matching with the protruding part 2 on the wallboard, and the other f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com