Evenly distributed variable-speed leak-proof container

A leak-proof, gear box technology, applied in transmission boxes, transmission parts, components with teeth, etc., can solve problems such as poor adaptability, and achieve the effects of simple implementation, high economic added value, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

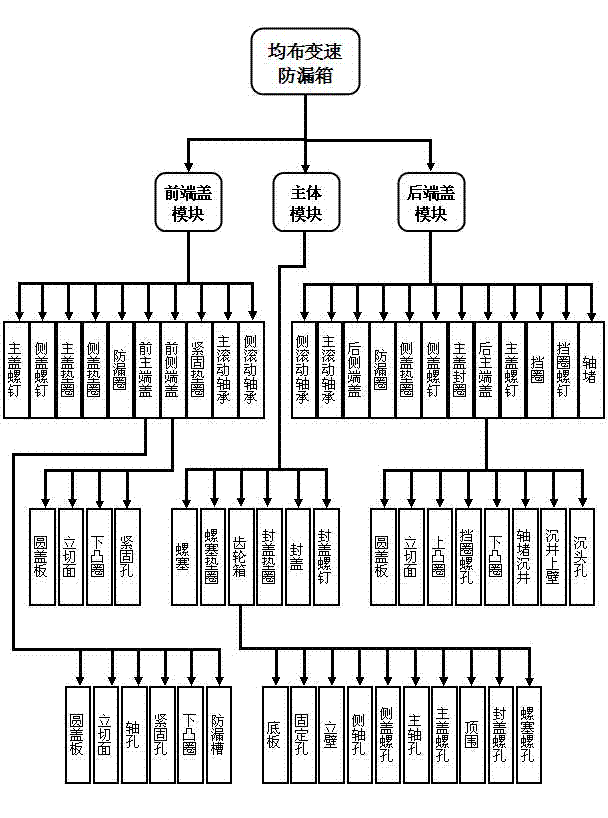

[0039] As a technical proposal for product manufacturing, the present invention can implement the proposal through the organic combination of corresponding parts. The product organization structure of an embodiment of the present invention is as follows: figure 1 shown.

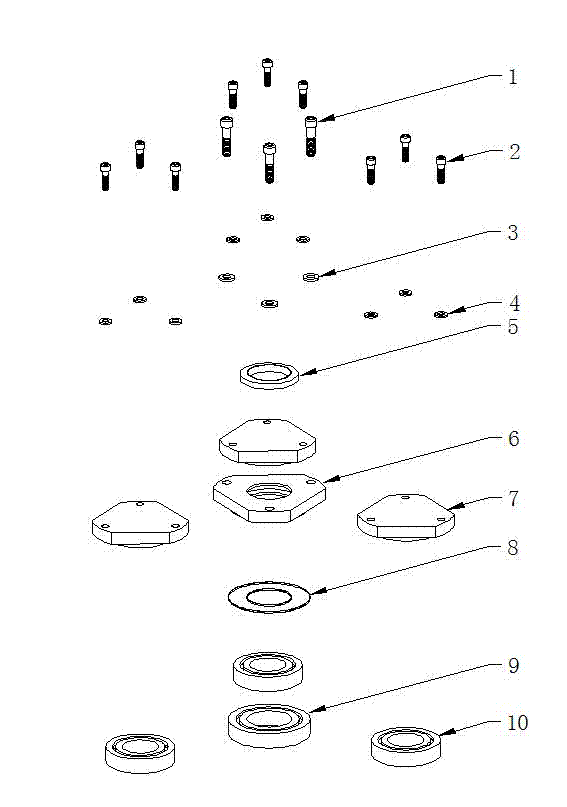

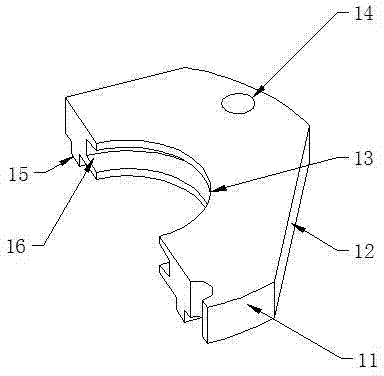

[0040] figure 1 Among them, the product is composed of three modules: the front cover, the main body and the rear cover; among them, the front cover module consists of the main cover screw, the side cover screw, the main cover gasket, the side cover gasket, the leak-proof ring, the front main cover, the front side The end cover, fastening washer, main rolling bearing and side rolling bearing are composed of ten parts. The main module is composed of six parts: screw plug, screw plug washer, gearbox, cover gasket, cover and cover screw. The rear end cover module is composed of Side rolling bearing, main rolling bearing, rear end cover, anti-leakage ring, side cover gasket, side cover screw, main cover sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com