In-situ testing system for flight control system loading mechanism

An in-situ test and aircraft control technology, applied in the field of aircraft control system test system, can solve the problems of lack of testing and testing equipment for the load mechanism of the aircraft control system, restricting the development of aviation maintenance support work, increasing the workload of disassembly and assembly of the load mechanism, etc., to achieve Simple structure, safety test, and the effect of improving the integrity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

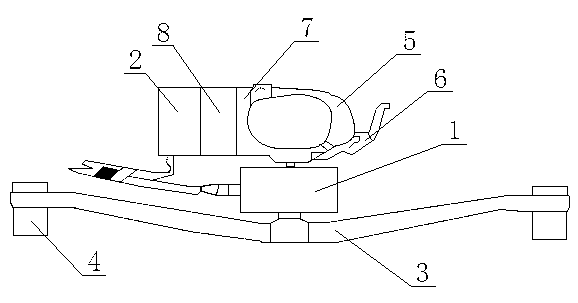

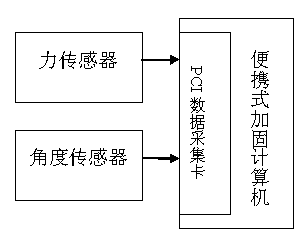

[0014] Specific embodiments: an in-situ test system for the load mechanism of an aircraft control system, the system includes a portable reinforced computer and a test device, the test device includes a joystick and a driving rod fixture, and a force sensor 1 is connected between the joystick and the driving rod fixture , Angle sensor 2 is installed on the steering rod fixture, and force sensor 1 and angle sensor 2 are electrically connected with the PCI data acquisition card inserted on the portable reinforced computer respectively.

[0015] In order to facilitate the operation of the joystick, the joystick includes a connecting rod 3 and handles 4 connected to both ends of the connecting rod 3 , and the middle part of the connecting rod 3 is connected to the force sensor 1 .

[0016] In order to facilitate the test device of the present invention to be installed on the steering column, the above-mentioned steering column clamp includes a clip 5 and a clamping device 6 for con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com