Shell-rotation tester for muddy water resistance of sealing ring and testing method thereof

A sealing ring and testing machine technology, which is applied in the use of liquid/vacuum degree for liquid tightness measurement, by detecting the appearance of fluid at the leak point, etc. Failure and other problems, to achieve the effect of improving reliability and service life, reasonable steps, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

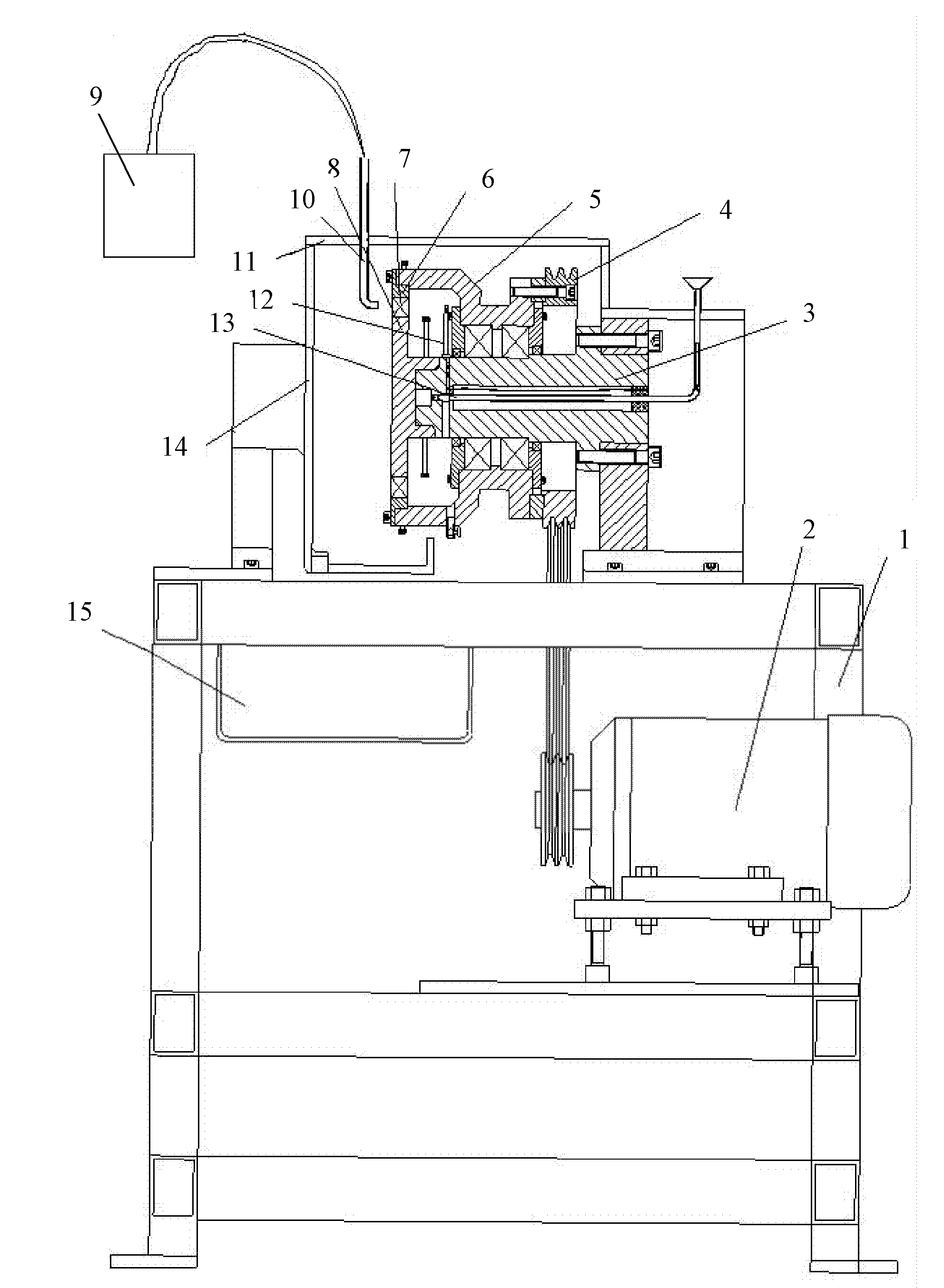

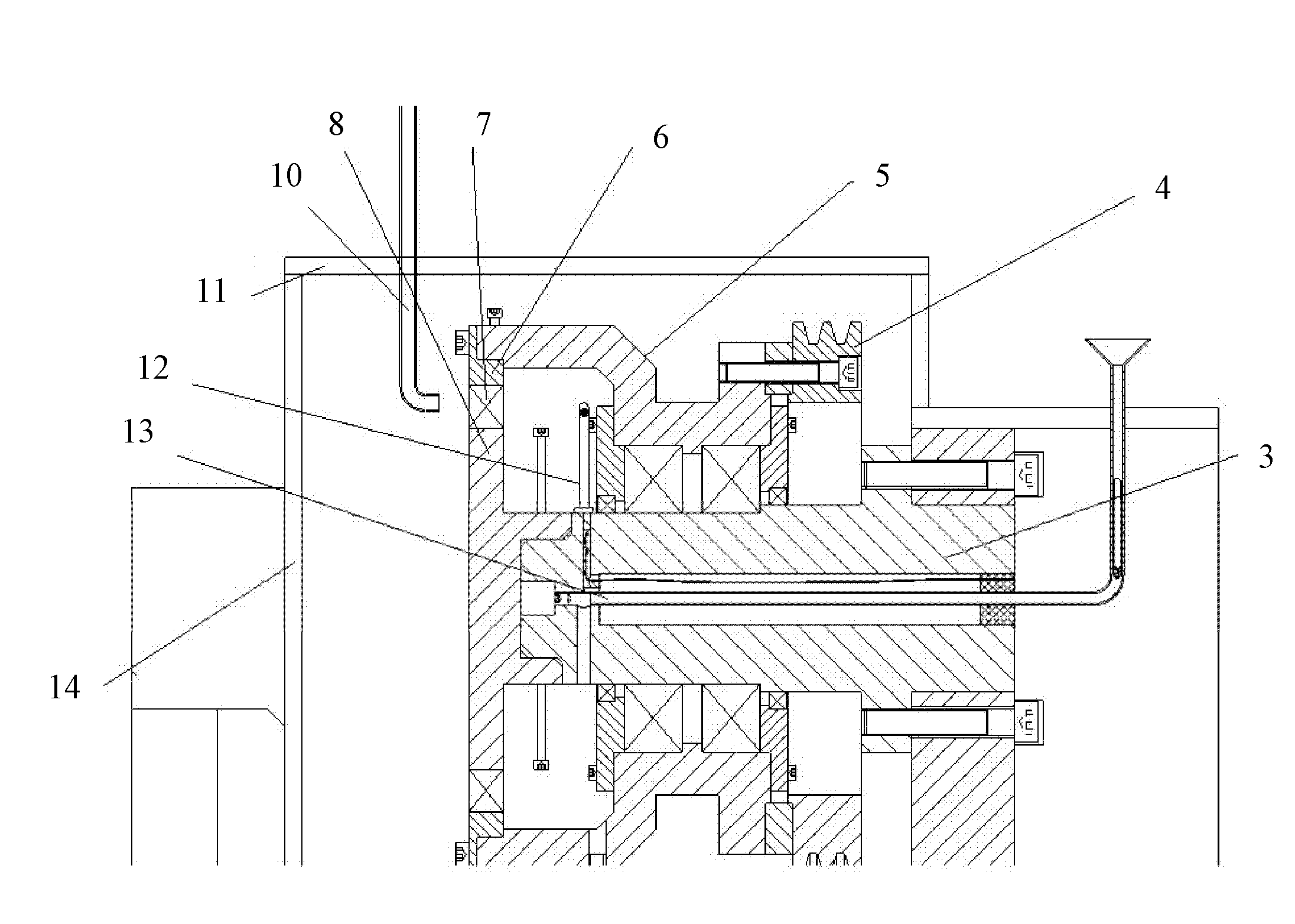

[0021] Such as figure 1 with figure 2 As shown, the sealing ring anti-mudwater performance shell rotation test machine includes a bench 1, a pulley 4, an eccentric test shaft 8, muddy water mixing and spraying equipment 9 and an oil injection pipe 13, and a motor 2 is arranged in the bench 1 and on the table. , fixed main shaft 3, rotating chamber 5 and muddy water shield 11, described rotating chamber 5 is provided with heating pipe 12, described rotating chamber 5 is connected and fixed with belt pulley 4 by screw, described in rotating chamber 5 The cavity eccentric disk 6 is arranged on the upper part, the eccentric test shaft 8 is arranged on the fixed main shaft 3, the protective cover door 14 is arranged on the muddy water protective cover 11, and the muddy water injection pipe is arranged on the muddy water mixing and spraying equipment 9 10. The muddy water injection pipe 10 is inserted into the hole provided on the muddy water protective cover 11, and a muddy water...

Embodiment 2

[0029] With embodiment 1, the difference is that its test method of the anti-mud water performance shell test machine of the sealing ring also includes the following steps:

[0030] The sixth step, repeat the test: use two sealing rings of the same model specification to repeat the above steps for the test.

Embodiment 3

[0032] With embodiment 1, the difference is that its test method of the anti-mud water performance shell test machine of the sealing ring also includes the following steps:

[0033] The sixth step, repeat the test: use six sealing rings of the same model specification to repeat the above steps for the test.

[0034] Like this when in use, sealing ring anti-mud water performance shell of the present invention rotates testing machine and test method thereof, and rotating cavity 5 is used for containing test liquid and installing sealing ring 7, and sealing ring 7 is installed on the testing machine, in certain test Under the condition of operation, spray muddy water to the outer end of the sealing ring 7 regularly, so as to test the muddy water-proof sealing performance of the sealing ring 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com