Method for accurately controlling photographic density during radiographic inspection

A technology of precise control and radiographic detection, which is used in material analysis using radiation, photographic dosimeters, dosimeters, etc., and can solve the problems of cumbersome exposure curve production, inability to obtain blackness values, and inconvenient radiographic detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

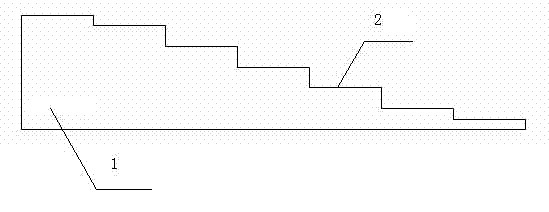

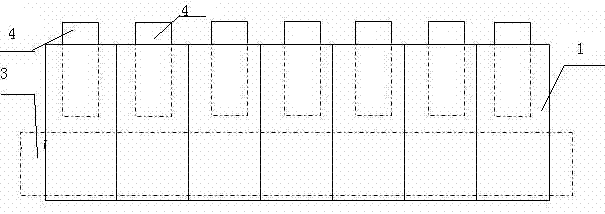

[0016] 1. Exposure: Under the condition that the radiation source, film, intensifying screen and darkroom processing conditions remain unchanged, carry out transillumination on the stepped test block 1. Before the transillumination, the film 3 is pressed under the stepped test block 1, and at the same time, a radiation detector 4 capable of measuring the cumulative dose is placed under the stepped test block 1, and the cumulative dose data is cleared. Place the image quality meter, intensifying screen, etc. under normal transillumination, place the intensifying screen under the film 3, place the image quality meter on the ladder test block 1 on the source side, and place the image quality meter on the ladder test block 1 on the source side. On the side of the ladder test block close to the radiation source; place a radiation dosimeter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com