Stagnation temperature computing method of bending steel members

A critical temperature, calculation method technology, applied in building construction, investigation phase/state change, construction, etc., can solve problems such as cumbersome process and large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 (theoretical description and deduction for supporting the establishment of the implementation steps of the technical solution method of the present invention)

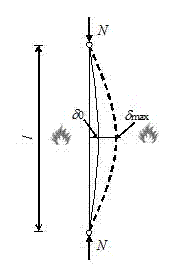

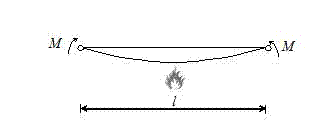

[0029] Under fire, as the internal temperature of the steel structure rises, the bearing capacity of the steel structure will decrease. When the bearing capacity of the structure decreases to be equal to the combined effect produced by the external action (including the temperature action), the structure will reach the fire resistance bearing capacity. limit state. The limit state check calculation of the bearing capacity of steel members at high temperature can adopt a form similar to that at room temperature specified in the current steel structure design code. The bearing capacity of compression-bending members is generally controlled by the overall stability. The limit state in this case can be expressed by the following formula:

[0030] Bending around the strong x-axis: N ...

Embodiment 2

[0149] [0149] Embodiment 2 (concrete calculation example for supporting the feasibility and practicability of the technical solution of the present invention)

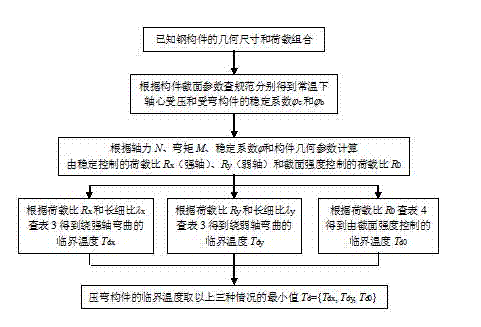

[0150] The calculation method of the critical temperature of the bending steel member is as follows: image 3 As shown, the specific steps are as follows:

[0151] (1) In the design of general steel structures, the geometric dimensions and load combinations of steel components are known. According to geometric dimensions such as cross-sectional area A, calculated length l, and radius of gyration r, the slenderness ratio of components can be calculated l=l / r. According to the length The fine ratio can be obtained from the "Code for Design of Steel Structures" GB50017: 2003, and the stability coefficient j of axial compression members around the strong axis and weak axis at room temperature can be found x , j y ;According to the geometric dimensions such as section moment of inertia I, section modulus W, slenderness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com