High-voltage power cable nondestructive detection device

A technology of non-destructive testing and high-voltage power, applied in the direction of testing dielectric strength, etc., can solve the problems of high-voltage cable withstand voltage test with long distance and large capacity, unable to detect local hidden defects of high-voltage power cables, etc., to reduce volume, Solve the heat dissipation problem and suppress the effect of high-frequency interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

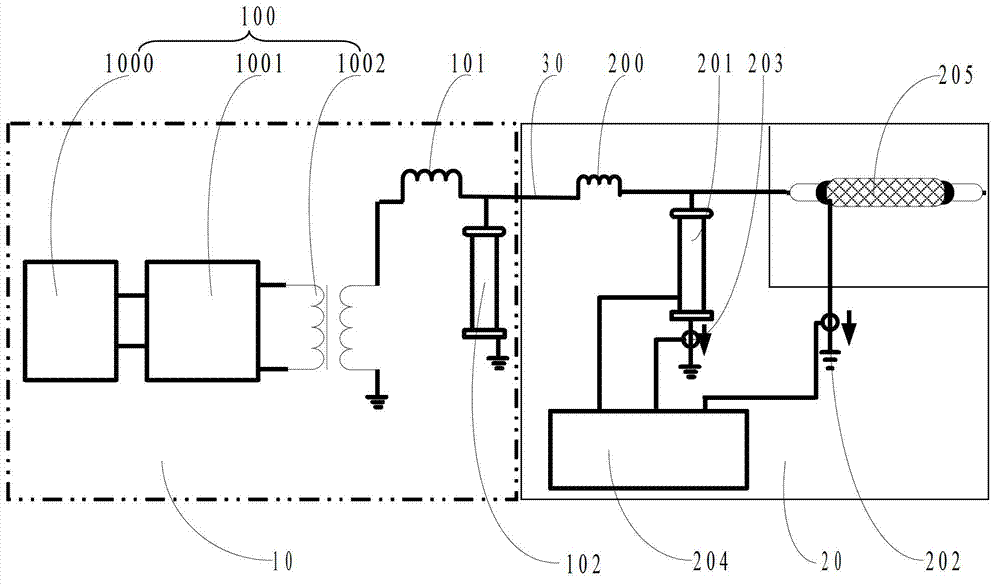

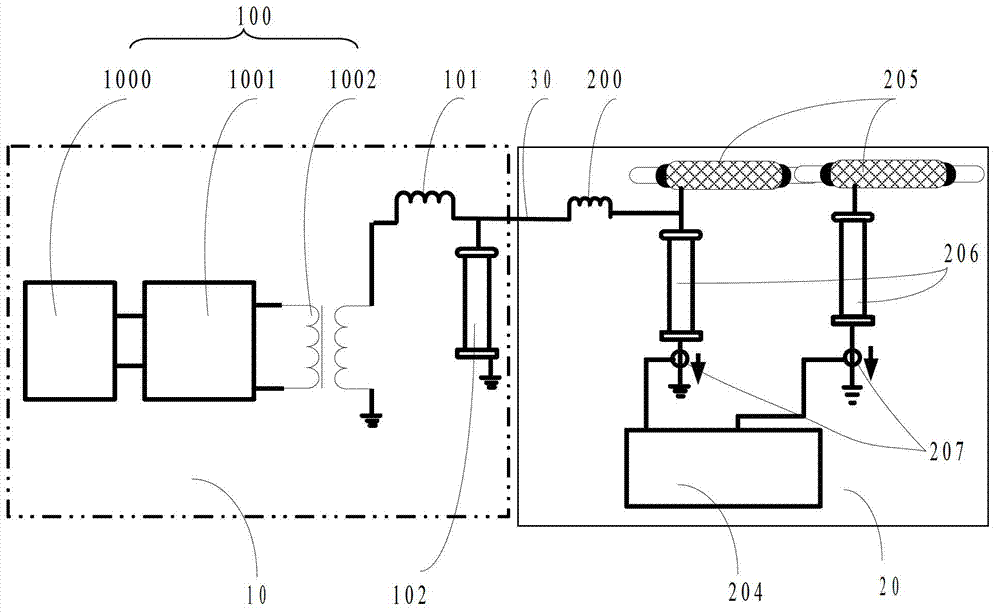

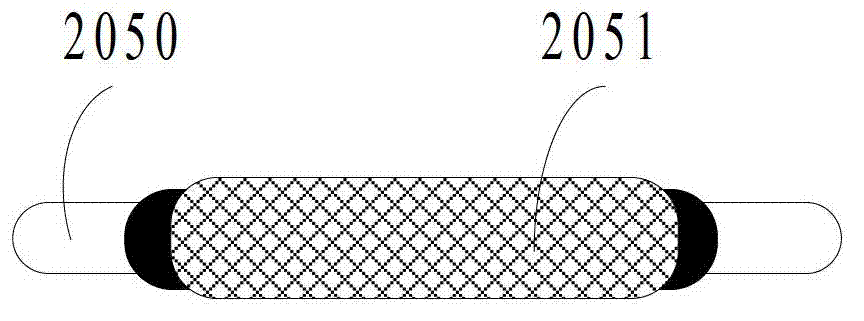

[0032] like Figure 1 to Figure 3 As shown, a non-destructive testing device for high-voltage power cables is used to detect defects in power cables, including an AC withstand voltage testing system 10 and a partial discharge testing system 20; the AC withstand voltage testing system 10 includes a power supply 100, a high-voltage reactance 101 and A voltage divider, the power supply 100, the high voltage reactance 101 and the voltage divider 102 are connected in series to form a loop. By setting the high-voltage reactance 101, the energy of the magnetic field in the inductance and the electric field energy of the capacitance of the tested cable 205 are used to compensate each other, so that the voltage on the tested cable 205 is Q times the voltage of the power supply 100, and the capacity of the power supply 100 is 100% of the capacity of the tested cable 205. 1 / Q ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inductance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com