Slide switch

A sliding switch and slider technology, which is applied in the direction of electric switches, contact drive mechanisms, seat belts in cars, etc., can solve the problems of miniaturization difficulty and length increase, and achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

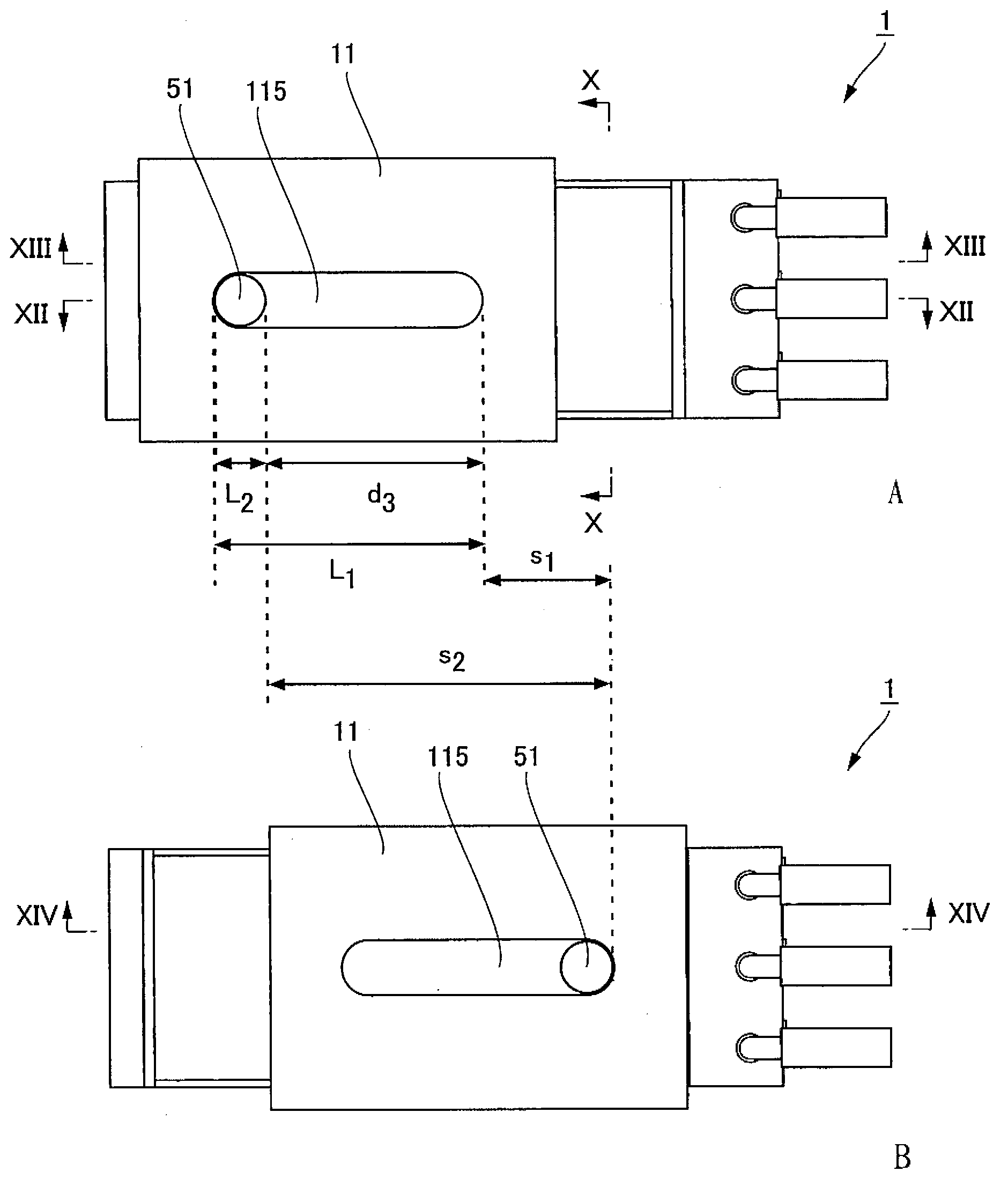

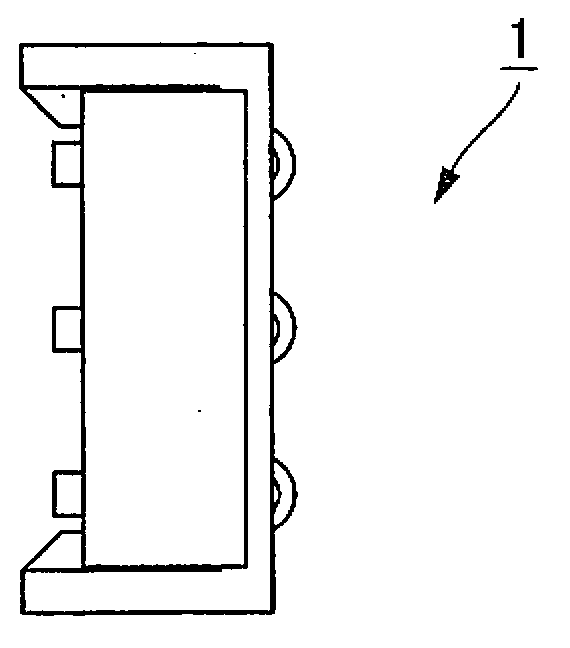

[0027] figure 1 In the front view of the slide switch 1 of the first embodiment showing the slider 11 at the initial position, A indicates the slider 11 at the initial position, and B indicates the slider 11 at the post-operation position. figure 2 A bottom view showing the slide switch 1 of the first embodiment, image 3 represents its left side view, Figure 4 represents its right side view, Figure 5 Indicates its rear view. Image 6 A perspective view of the slide switch 1 viewed from the front side is shown, Figure 7 Represents its exploded perspective view, Figure 8 A perspective view of the slide switch 1 viewed from the back side is shown, Figure 9 Indicates its exploded perspective view. In addition, three wire harnesses 151 to 153 are simultaneously shown in each of several figures, figure 1 and Image 6 In the middle, the movable portion 51 is also shown.

[0028] The slide switch 1 includes a slider 11 , a contact piece 12 , three terminals 131 to 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com