Grouping method for power lithium ion batteries

A lithium-ion battery and battery technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, secondary battery repair/maintenance, etc., can solve problems such as poor safety, difficulty in battery sorting and grouping, and poor consistency, and achieve electrical performance The effect of improved stability, convenient distribution and assembly, and consistent internal resistance of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the method for configuring power lithium-ion batteries in this embodiment, for the convenience of explanation, the four levels of a1, a2, a3, and a4 are used for the division in step 1; The batteries of each gear of a3 and a4 are divided into two gears, which are divided into eight gears: a1b1, a1b2, a2b1, a2b2, a3b1, a3b2, a4b1, and a4b2; , A2b1, a2b2, a3b1, a3b2, a4b1, and a4b2 are divided into two levels, and finally divided into a1b1c1, a1b1c2, a1b2c1, a1b2c2, a2b1c1, a2b1c2, a2b2c1, a2b2c2, a3b1c1, a3b1c2, a3b1c1, a3b1c4 , A4b1c2, a4b2c1, a4b2c2, sixteen gears; however, in the actual assembly process, the number of bins can be divided according to actual needs, and is not limited to the number of bins used in this embodiment.

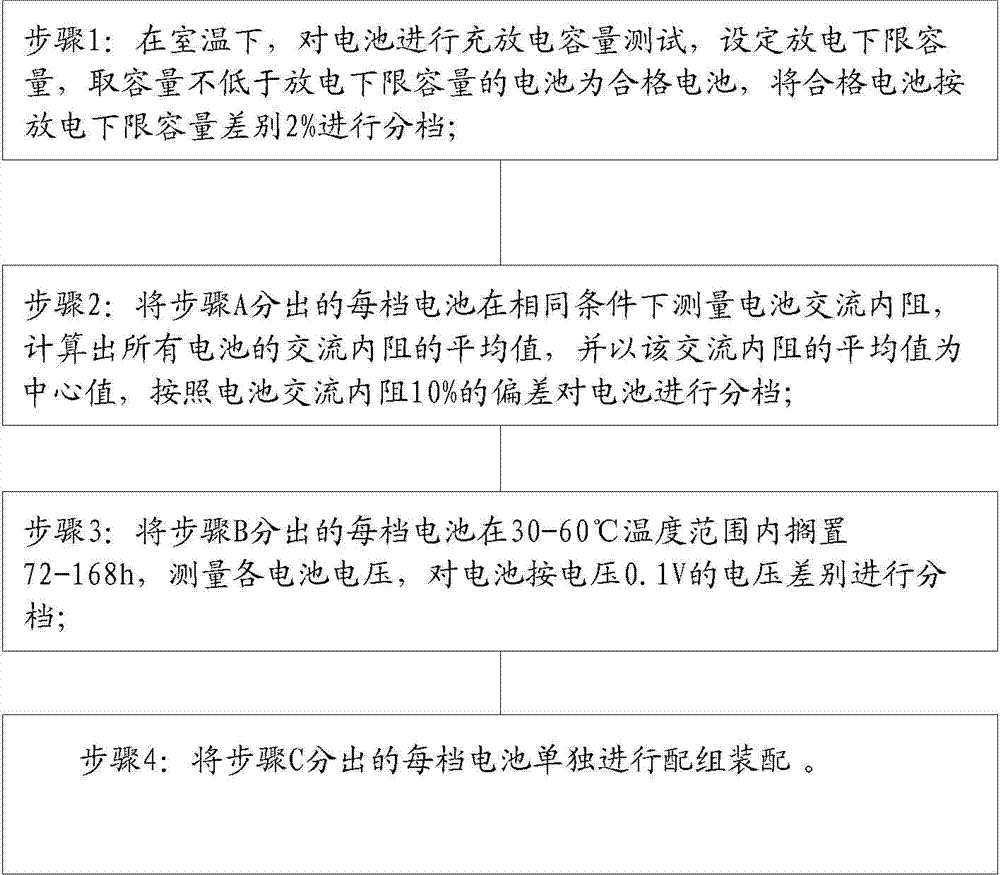

[0033] A method of assembling power lithium-ion batteries for assembling single cells before assembling the lithium-ion power battery pack includes the following steps:

[0034] Step 1: At room temperature, test the charge and discharge capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com