Vacuum sintering furnace combined movable protection charging glove box

A technology for vacuum sintering furnaces and glove boxes, which is applied to manipulators, manufacturing tools, etc. It can solve the problems of easy impact caused by the operation of forks, inconvenient loading operation, and high work intensity, etc., and achieves stable and reliable operation, convenient operation, and lightening The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

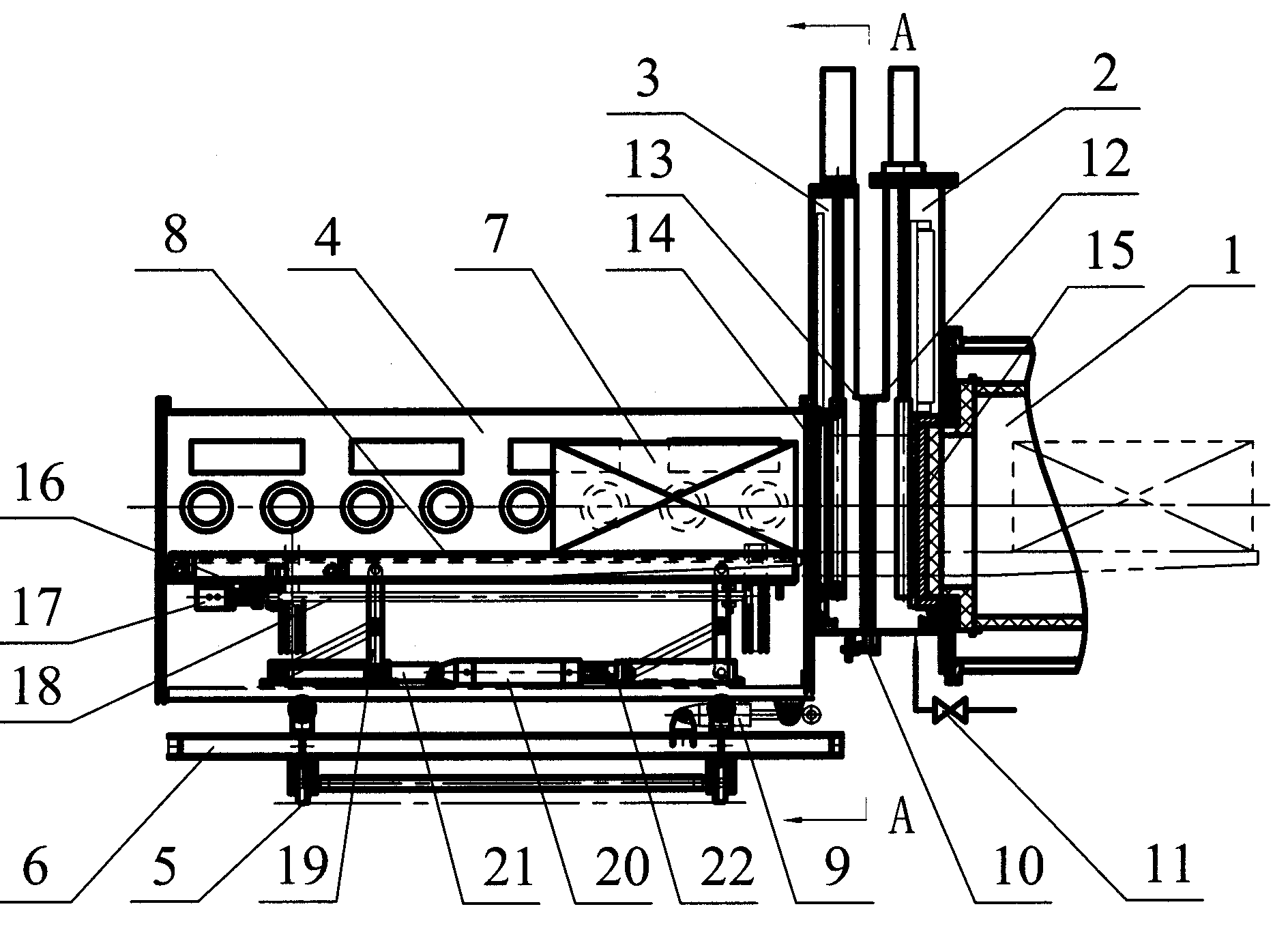

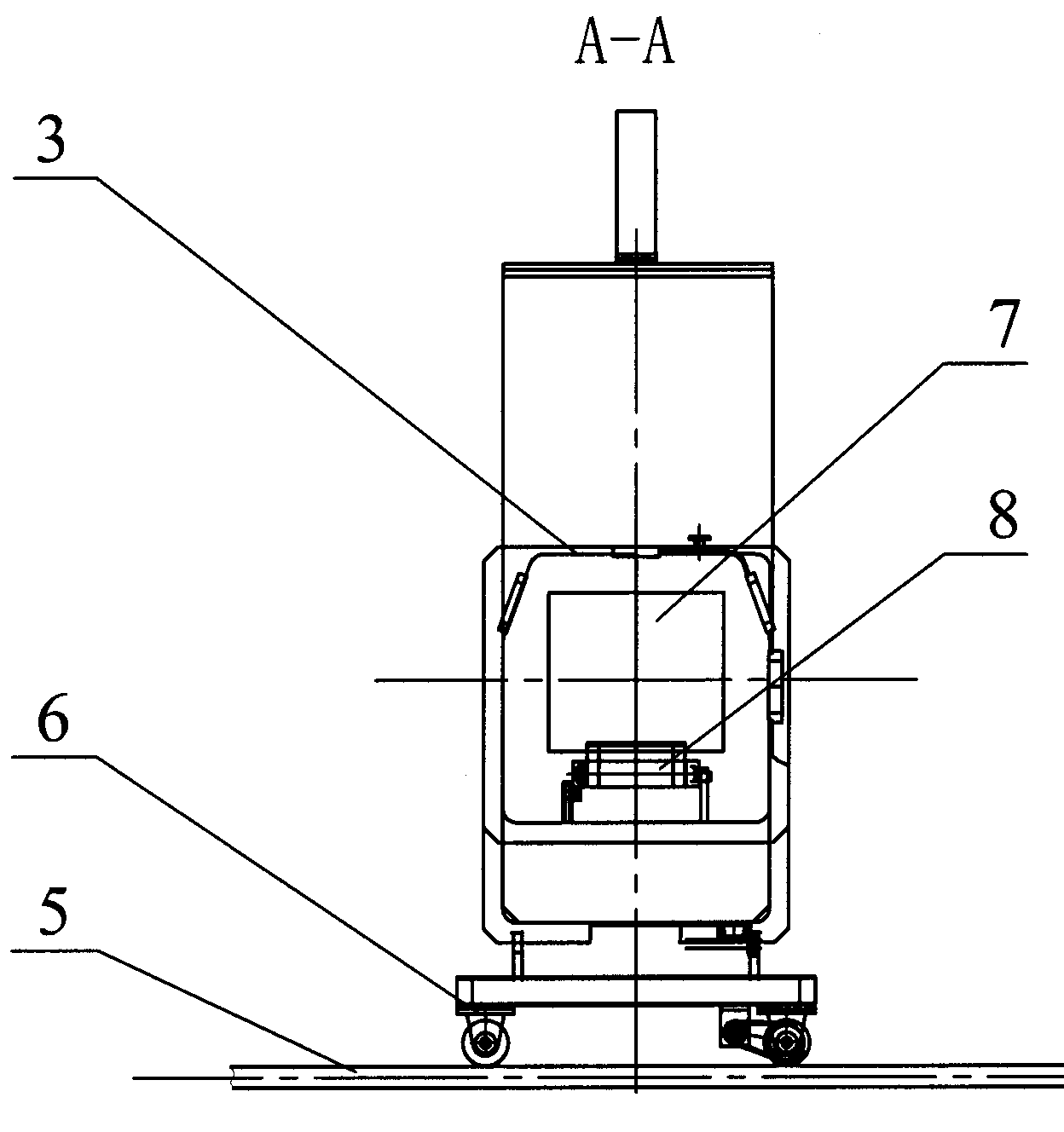

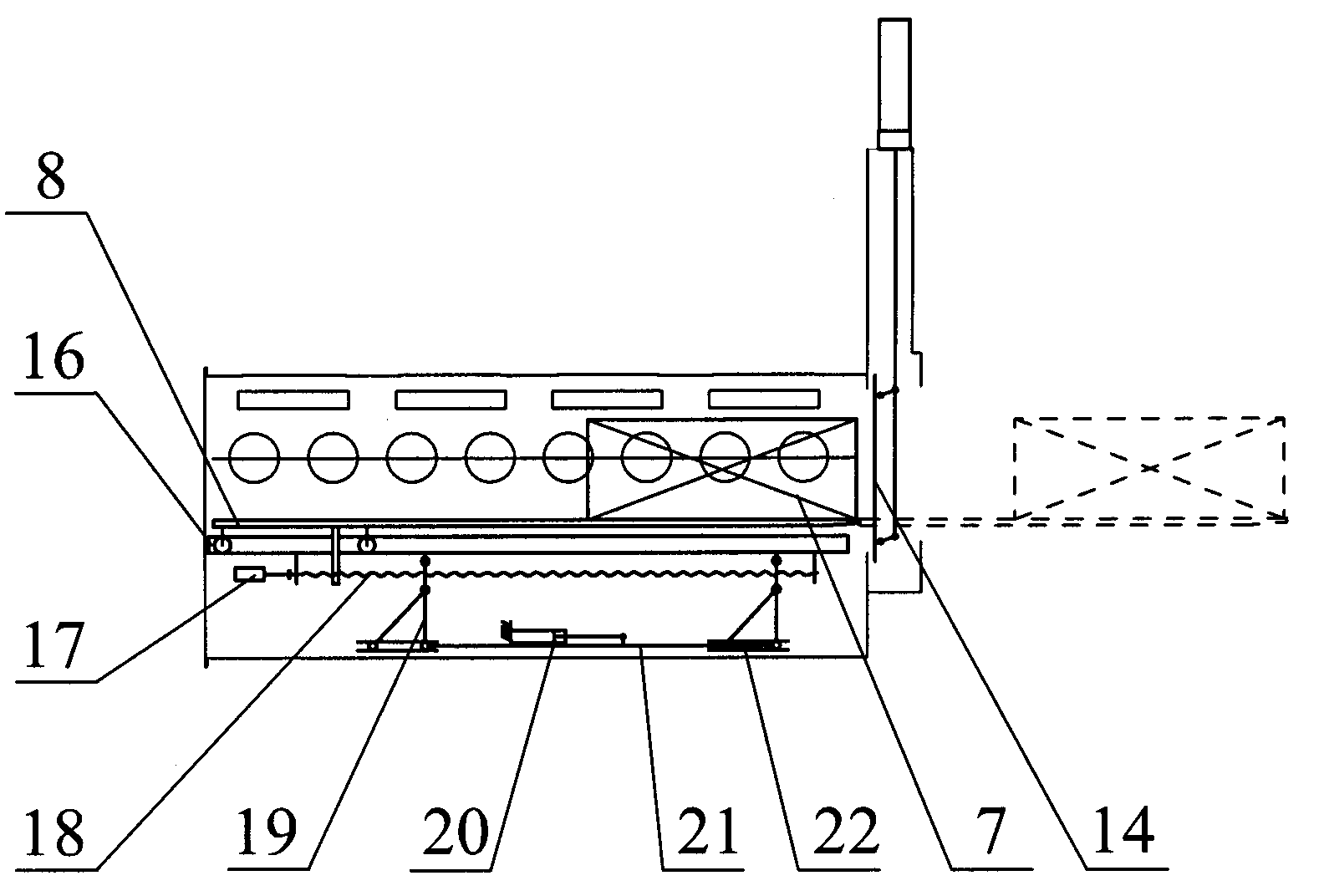

[0014] according to Figure 1~4 The specific structure of the present invention will be described in detail. The main body of the vacuum sintering furnace combined with a mobile protective charging glove box is improved on the basis of the structure of the existing protective charging glove box. It includes a box body 4 of a protective charging glove box placed on a transversely moving vehicle 6 shared with multiple sintering furnaces 1, and a gate valve type glove box door 3 assembled on the box body 4, which is respectively arranged on each sintering furnace 1 and the gate valve type sintering furnace door 2 docked with the gate valve type glove box door 3 and parts such as the control system. Wherein the structure of laterally moving car 6 is as Figure 1~2 As shown, the laterally moving vehicle 6 is driven to move on the ground track 5, so that the box body 4 of the protective charging glove box placed on the laterally moving vehicle 6 is docked with the sintering furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com