Joint attaching structural element to composite part and aircraft including the joint

A technology of composite parts and structural elements, applied in aircraft parts, aircraft indicating devices, aircraft lighting protectors, etc., can solve problems such as expensive, expensive solutions, and increased weight of aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

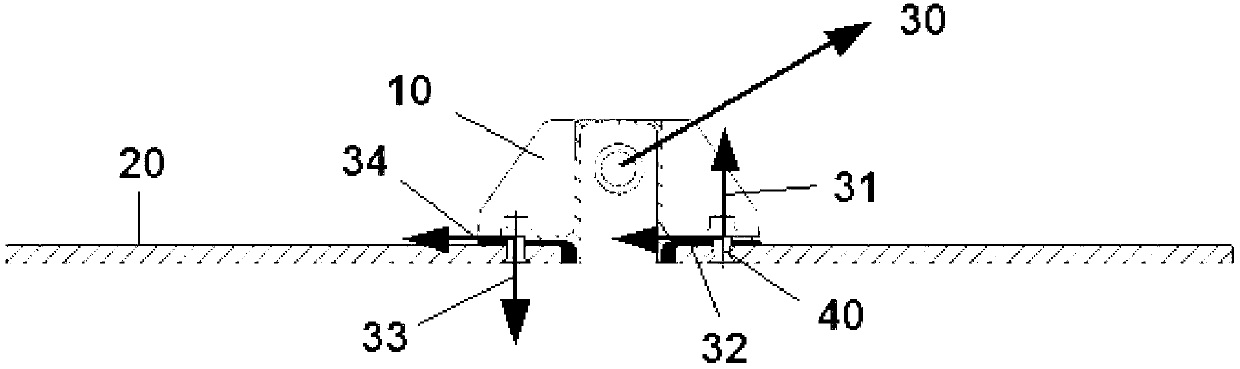

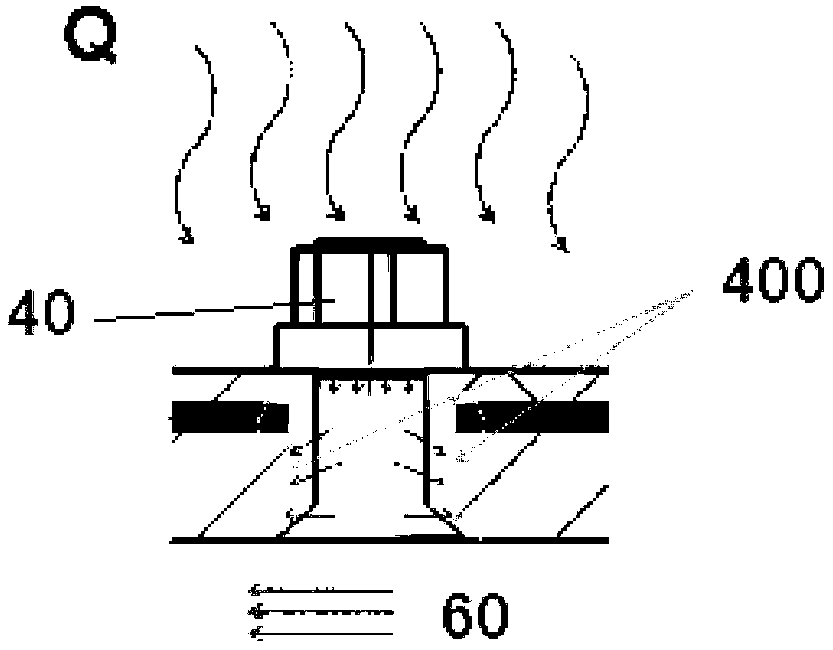

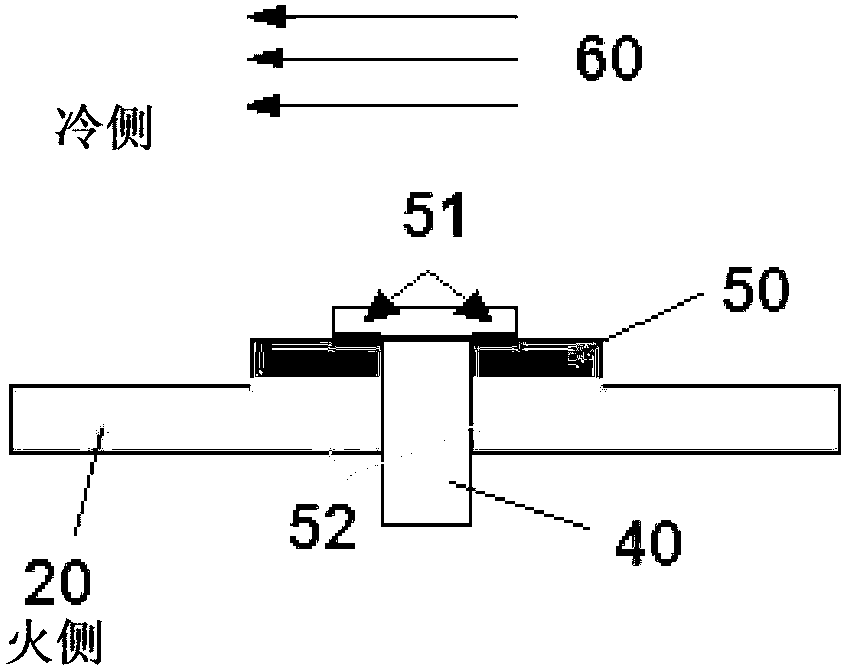

[0016] In some parts of the aircraft structure, such as figure 1 As shown, it is necessary to connect a structural element 10 (typically metallic) with an element or component 20 made of composite material. In some cases these structural elements 10 are subjected to high structural loads 30 from the aircraft. Typically, the structural element 10 is connected to the composite part 20 by metal attachments 40, typically rivets or bolts. In the event of a fire, the strength of the composite part 20 is greatly reduced, as it has been found that in composite structures subjected to high temperatures, the strength to forces (especially to vertical forces) is very critical, as figure 1 and figure 2 The same is the case in the prior art shown in .

[0017] It is common practice in the industry to protect structural elements 10 subjected to fire by the use of thermal lays or coatings comprising insulating materials of low thermal conductivity to reduce the temperature on the part be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com