Additive for improving quality of cut stem, as well as preparation method, device and application thereof

A technology of cut stems and quality, which is applied in the field of extraction of active ingredients of natural products, can solve the problems of obvious woody gas and local miscellaneous gas, low aroma and smoke concentration, and high irritation, and achieves short extraction time and extraction. The effect of low temperature and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

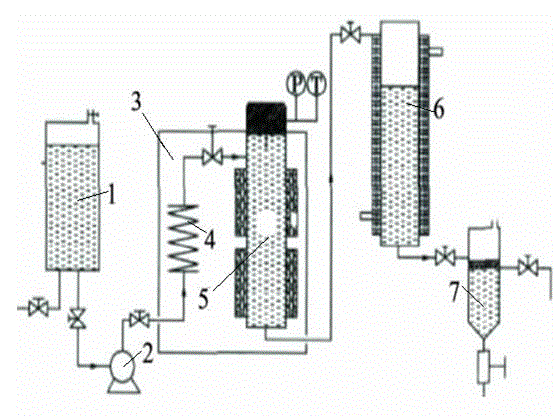

Method used

Image

Examples

Embodiment 1

[0020] Wash 100g of dried tea tree flowers with water, dry and pulverize it to 20 mesh powder, put it into the subcritical extraction equipment, deliver the deionized water to the preheater through the pressure pump, and add the water when it reaches 100℃ In the extraction tank, control the material-liquid ratio to 20ml / g. When the pressure of the extraction tank reaches 15Mpa, start timing. After 30 minutes of extraction, the extract will flow to the collector through the cooler. Add 50g of NaCl to the obtained extract and stir well to dissolve and break the emulsion. Then add CH in the extract at a ratio of 1:1 2 Cl 2 And mix well, let stand for 30min and separate after layering, collect CH 2 Cl 2 Add 40 g of anhydrous sodium sulfate, filter, collect the filtrate, collect the extract after concentration, and calculate the yield of tea tree flower essential oil by weighing.

[0021] Tea tree flower essential oil yield (%) = the weight of the collected essential oil extract (g) / ...

Embodiment 2

[0029] Wash 100g of dried tea tree flowers with water, dry and pulverize to 20 mesh powder, put it into a self-made subcritical extraction equipment, and deliver deionized water to the preheater through a pressure pump for preheating. When it reaches 110°C, the Water is added to the extraction tank, and the ratio of material to liquid is controlled at 30ml / g. When the pressure of the extraction tank reaches 10Mpa, the timing extraction is started. After 45 minutes of extraction, the extraction liquid flows to the collector through the cooler. Add 60g of NaCl to the obtained extract and stir well to dissolve and break the emulsion. Then add CH in the extract at a ratio of 1:1 2 Cl 2 And mix well, let stand for 50min, separate the liquid after layering, collect CH 2 Cl 2 Add 30 g of anhydrous sodium sulfate, filter, collect the filtrate, collect the extract after concentration, and calculate the yield of tea tree flower essential oil by weighing.

[0030] Tea tree flower essential...

Embodiment 3

[0038] Wash 100g of dried tea tree flowers with water, dry and pulverize to 20 mesh powder, put it into a self-made subcritical extraction equipment, and deliver deionized water to the preheater through a pressure pump for preheating. When it reaches 120°C, the Water is added to the extraction tank, and the ratio of material to liquid is controlled to 40ml / g. When the pressure of the extraction tank reaches 7Mpa, timing extraction is started. After 60 minutes of extraction, the extraction liquid flows to the collector through the cooler. Add 160g of NaCl to the obtained extract and stir well to dissolve and break the emulsion. Then add CH in the extract at a ratio of 1:1 2 Cl 2 And mix well, let stand for 60min, separate the liquid after layering, collect CH 2 Cl 2 Add 120 g of anhydrous sodium sulfate, filter, collect the filtrate, collect the extract after concentration, and calculate the yield of tea tree flower essential oil by weighing.

[0039] Tea tree flower essential oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com