Hole-free curtain wall direct material connection system

A curtain wall and direct material technology, applied in the field of external curtain wall connection design, can solve problems such as difficult implementation, tight upper floor height tolerance, tight upper plate thickness tolerance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

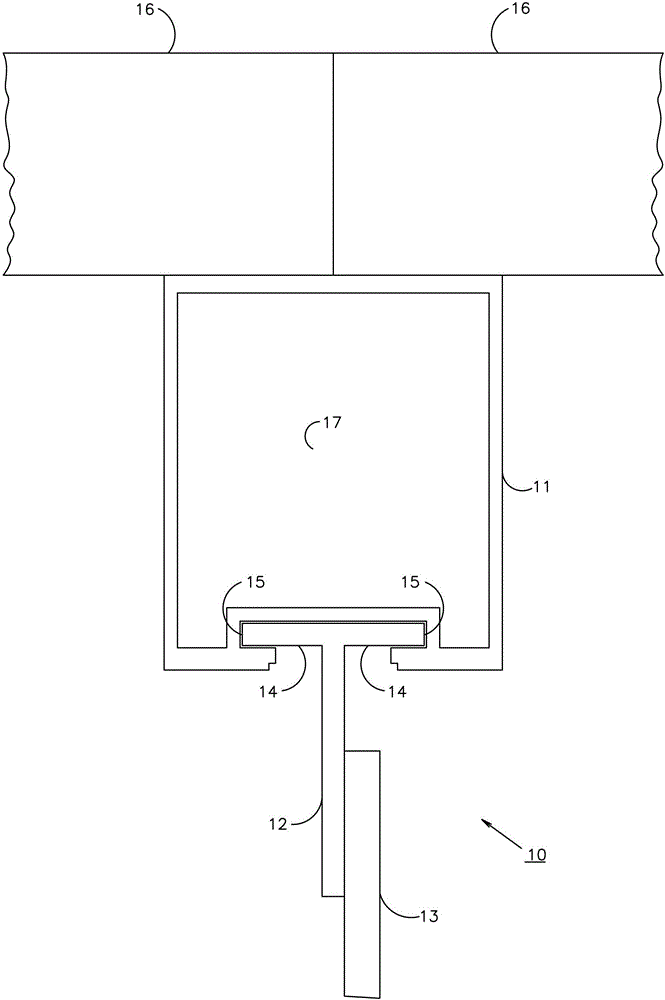

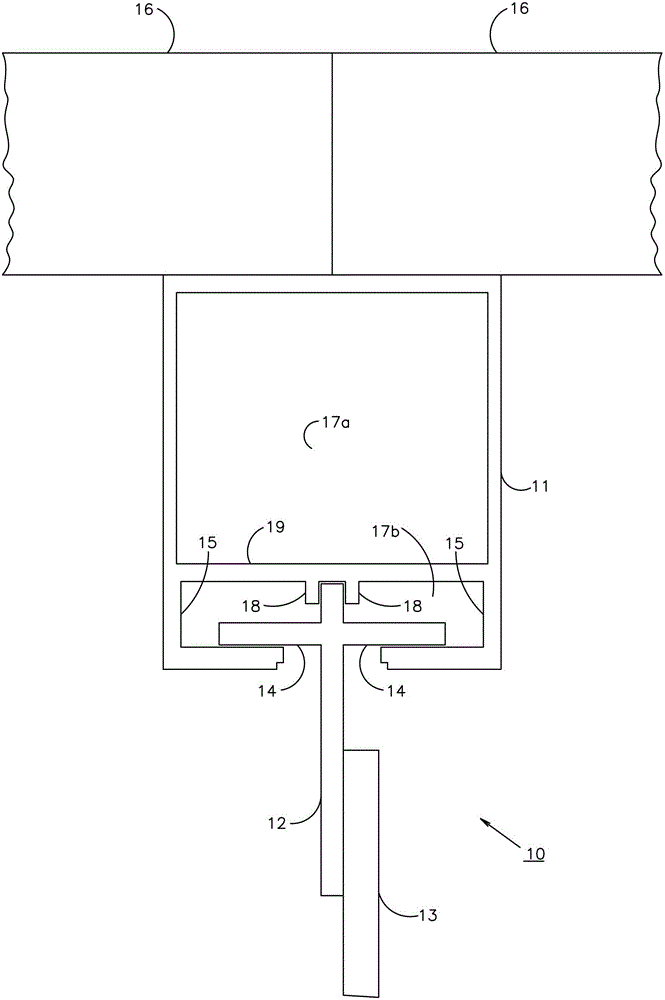

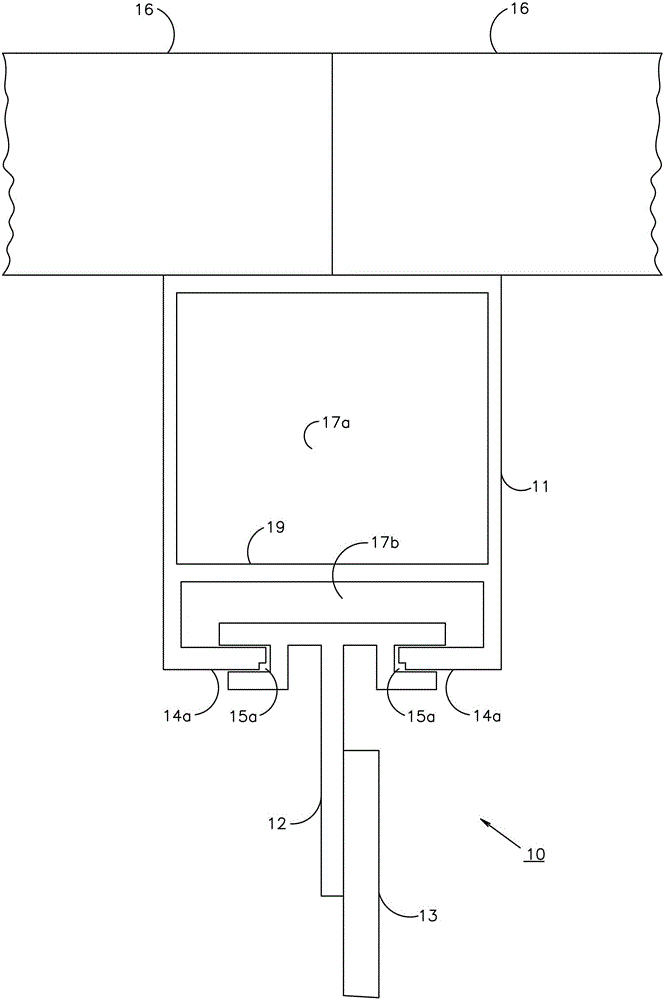

[0057] The embodiments of the present invention are described in detail below together with the accompanying drawings. The same reference numerals are used in the drawings and the implementation to represent the same component names.

[0058] In order to better describe the working principle of the present invention, the terms used in the present invention are listed below:

[0059] Mullion: One of several building elements, usually used in a vertical orientation, to structurally support a weather sealing exterior wall panel;

[0060] Straight material connection system: a structural system designed to transfer the reaction forces generated by dead load and wind load on the straight material to a structural support element in the building structure;

[0061] connector clip: a first component of a straight material connection system for transmitting reaction forces on the straight material to a second component of the straight material connection system; and

[0062] Structura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com