Connecting method of polyethylene composite tubes of steel wire gauze framework

A technology of polyethylene composite pipe and connection method, which is applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing components, etc., and can solve the problems of poor high pressure resistance performance of capacitive connection, pipeline affecting liquid transportation, high cost of crimping mold, etc. , to achieve the effect of firm connection, long-term safe operation and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

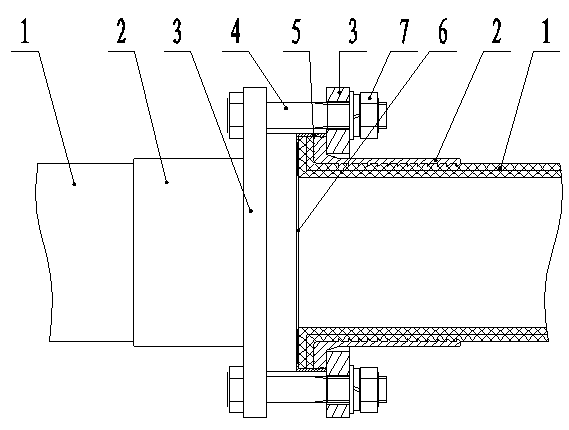

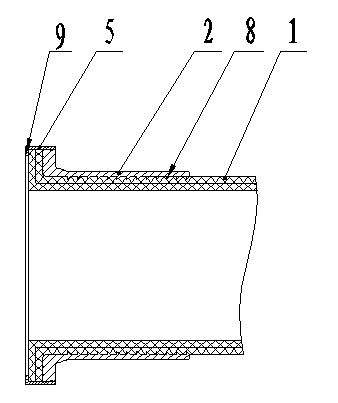

[0017] Example: in figure 1 In the process, the flange plate 3 is first set on the pipe body 1, and the pipe body 1 is connected with the metal sleeve 2 through the 90° outward flanging of the end. After the metal sleeve 2 is crimped, the inverted tooth 8 is pressed into the pipe body 1 inside. There is a groove on the outer circle of the end of the metal sleeve 2 . Utilize external force to press the inverted teeth of the inner circle of the end of the metal hoop 5 into the groove on the outer circle of the metal sleeve 2, so that the 90° outer flange at the end of the pipe body 1 is closely attached to the metal sleeve 2. The outer diameter of the sealing rubber washer 6 is slightly smaller than the inner diameter of the end face of the ferrule 5 . When connecting, put the sealing rubber gasket 6 between the inner diameters of the end faces of the two pipe bodies 1 and the end faces of the ferrule 5, and then fasten them into one body with bolts 4 and nuts 7.

[0018] exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com