Adsorption-type lamp box for detection of laser processed flexible circuit board

A flexible circuit board and laser processing technology, which is applied in the direction of optical testing flaws/defects, can solve the problem that the soft board cannot be attached to the scanner glass surface, etc., and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

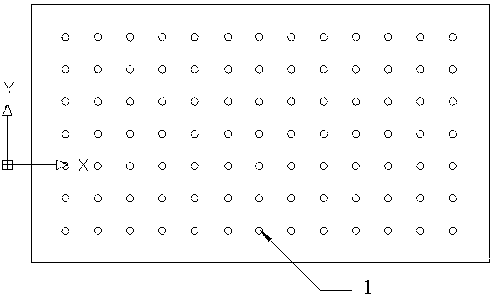

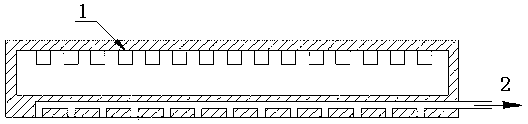

[0022] An adsorption light box for detection after laser processing of flexible circuit boards, including a glass surface, the glass surface has small holes in a dot matrix, and a suction device is provided on the side close to the glass surface in the light box, placed on the glass surface of the light box The soft board can be adsorbed on the glass surface under the suction state of the suction device.

[0023]

Embodiment 2

[0025] An adsorption light box for detection after laser processing of flexible circuit boards, including a glass surface, the glass surface has small holes in a dot matrix, and a suction device is provided on the side close to the glass surface in the light box, placed on the glass surface of the light box The soft board can be adsorbed on the glass surface under the suction state of the suction device.

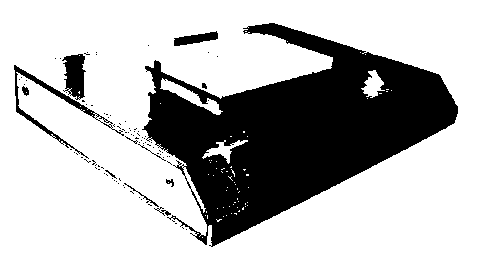

[0026] Make a lattice of small holes on the glass surface of the light box, and at the same time ensure the smoothness and flatness of the lattice surface on the glass surface; install an air suction device on the side of the added glass, such as image 3 , 4 As shown, the soft board on the glass surface of the light box can be tightly adsorbed on the glass under the suction state, and at the same time, the place other than the soft board of the light box needs to be covered with white paper (the edge of the white paper overlaps with the soft board, and the small area outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com