Lifting switch of automotive glass

A lift switch, automotive glass technology, applied in the direction of electric switches, flip/rocker switches, electrical components, etc., can solve the problems of complex assembly of lift switches and low production efficiency, and achieve good consistency in operation feel, high production efficiency, The lifting function is stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

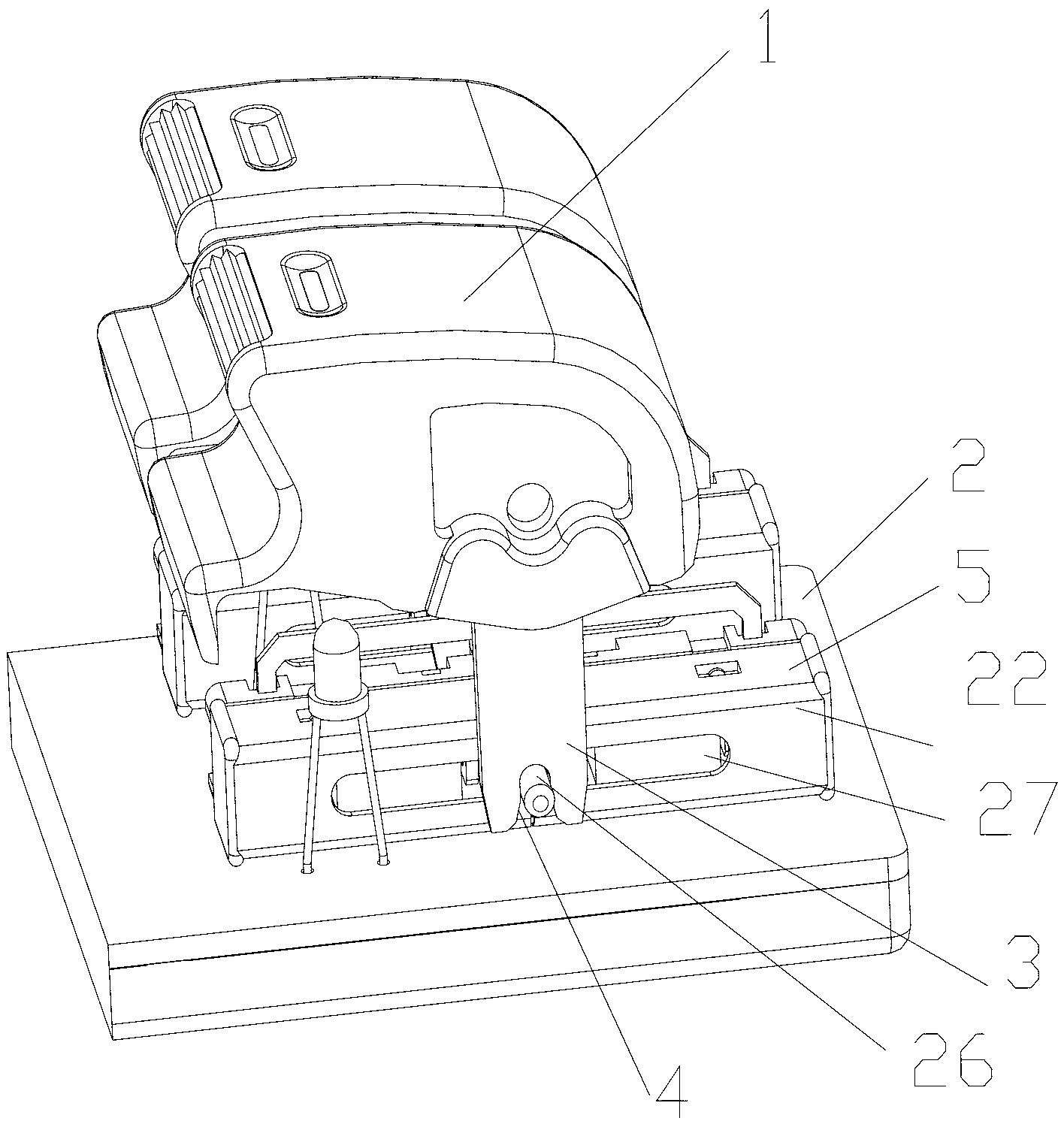

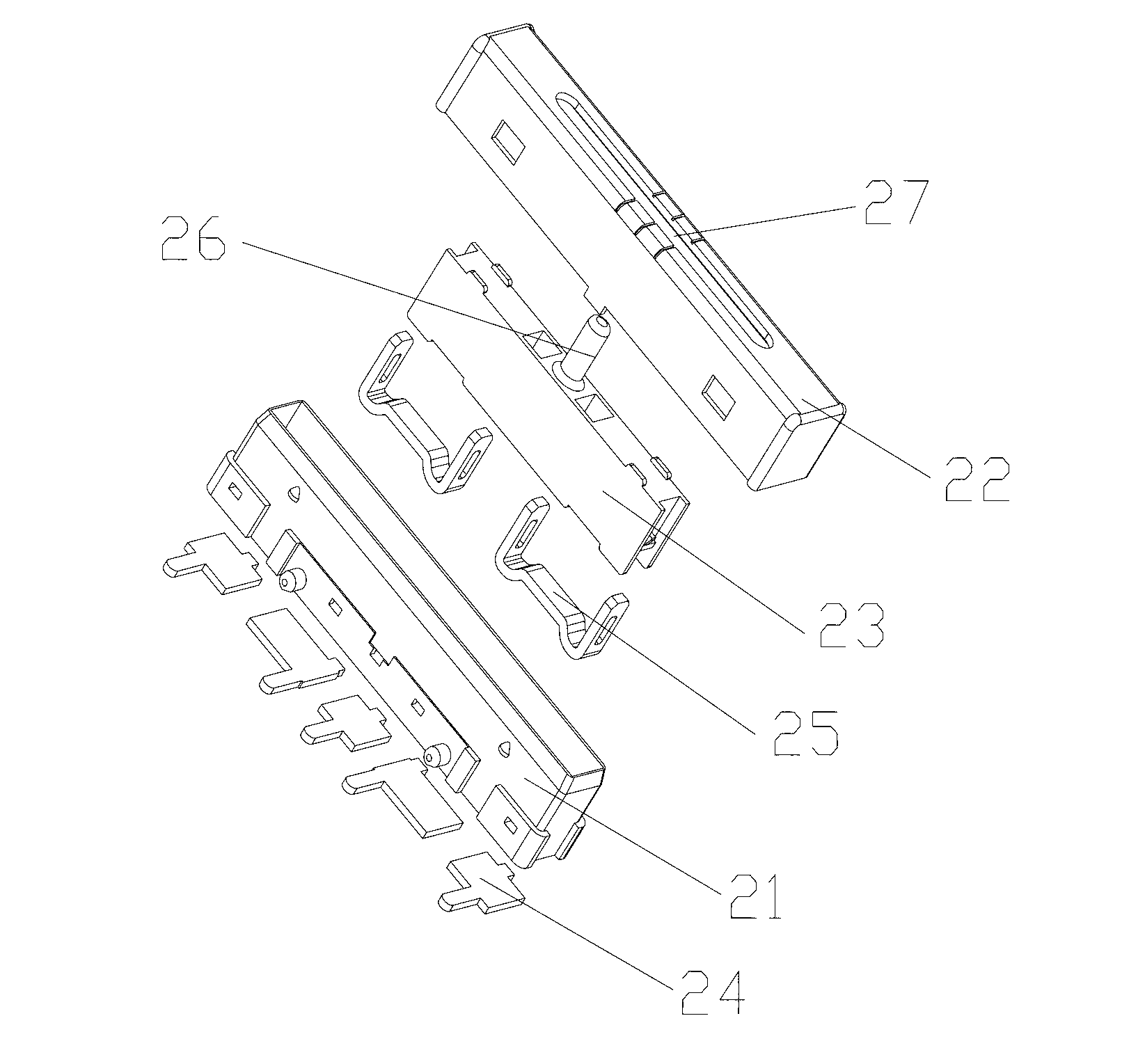

[0014] Examples such as figure 1 , figure 2 As shown, a kind of automobile glass lifting switch, comprises button 1, base 2, and described base 2 is provided with circuit board, is characterized in that: also comprises the toggle switch 5 that is assembled on circuit board, described toggle The switch 5 cooperates with the circuit board to realize the on-off of the switch, and the button 1 is provided with a lever 3 for controlling the on-off of the toggle switch 5 . The toggle switch 5 includes a socket 21, a slider 23, a casing 22 set on the socket 21, a set of static contacts 24 connected to the circuit board arranged on the socket 21; the socket 21 and the casing 22 An accommodating cavity is formed between them, and the slider 23 can be movably arranged in the accommodating cavity; the fixing device at the lower end of the slider 23 has a set of moving contacts 25 that match the static contacts 24; the housing 22 A track groove 27 is arranged on the top; the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com