Light guide alignment device for power tool

A technology of electric tools and guiding devices, which is applied to the attachments of sawing machines, manufacturing tools, metal processing equipment, etc., and can solve problems such as difficult to see shadow lines and user confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

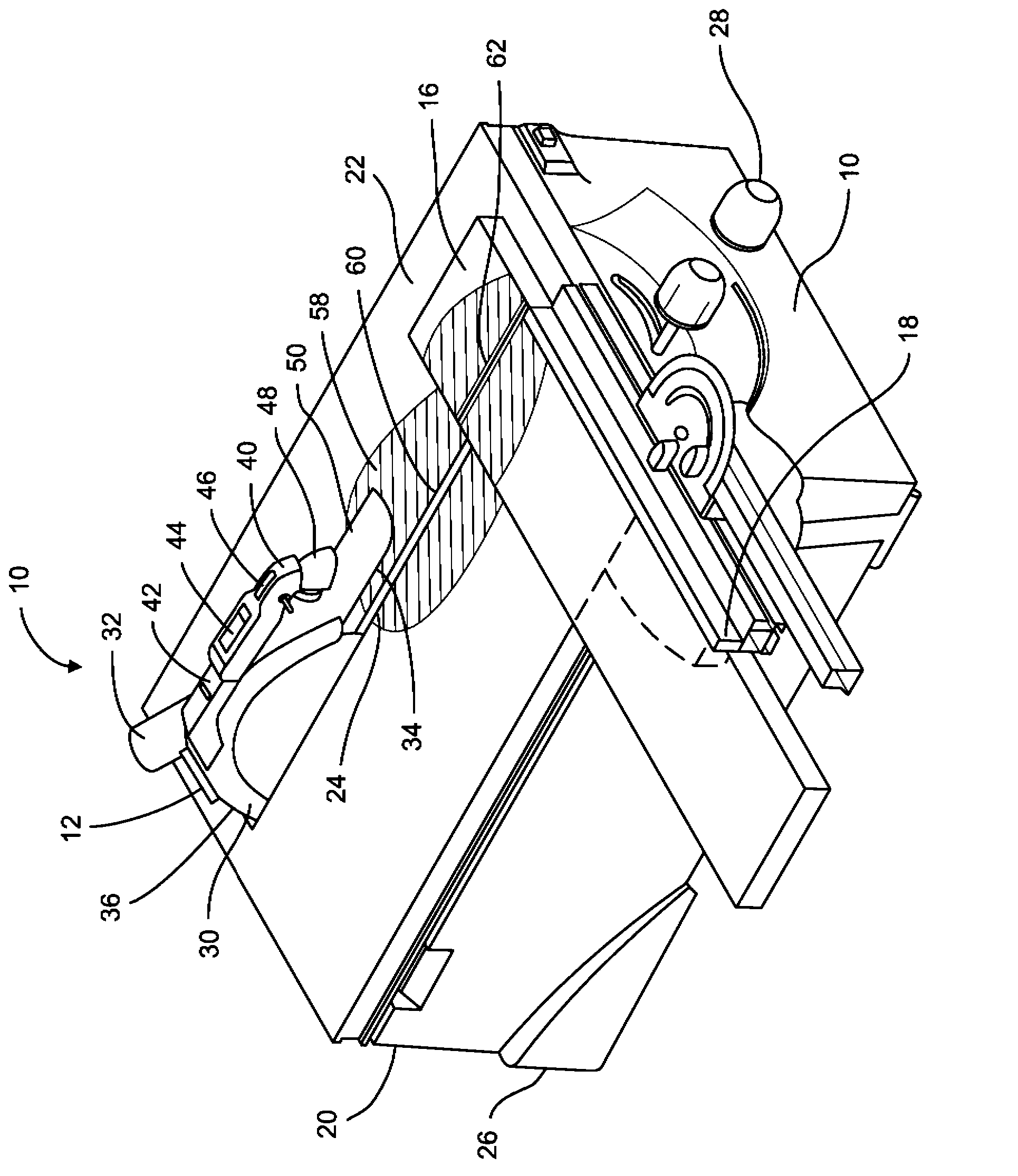

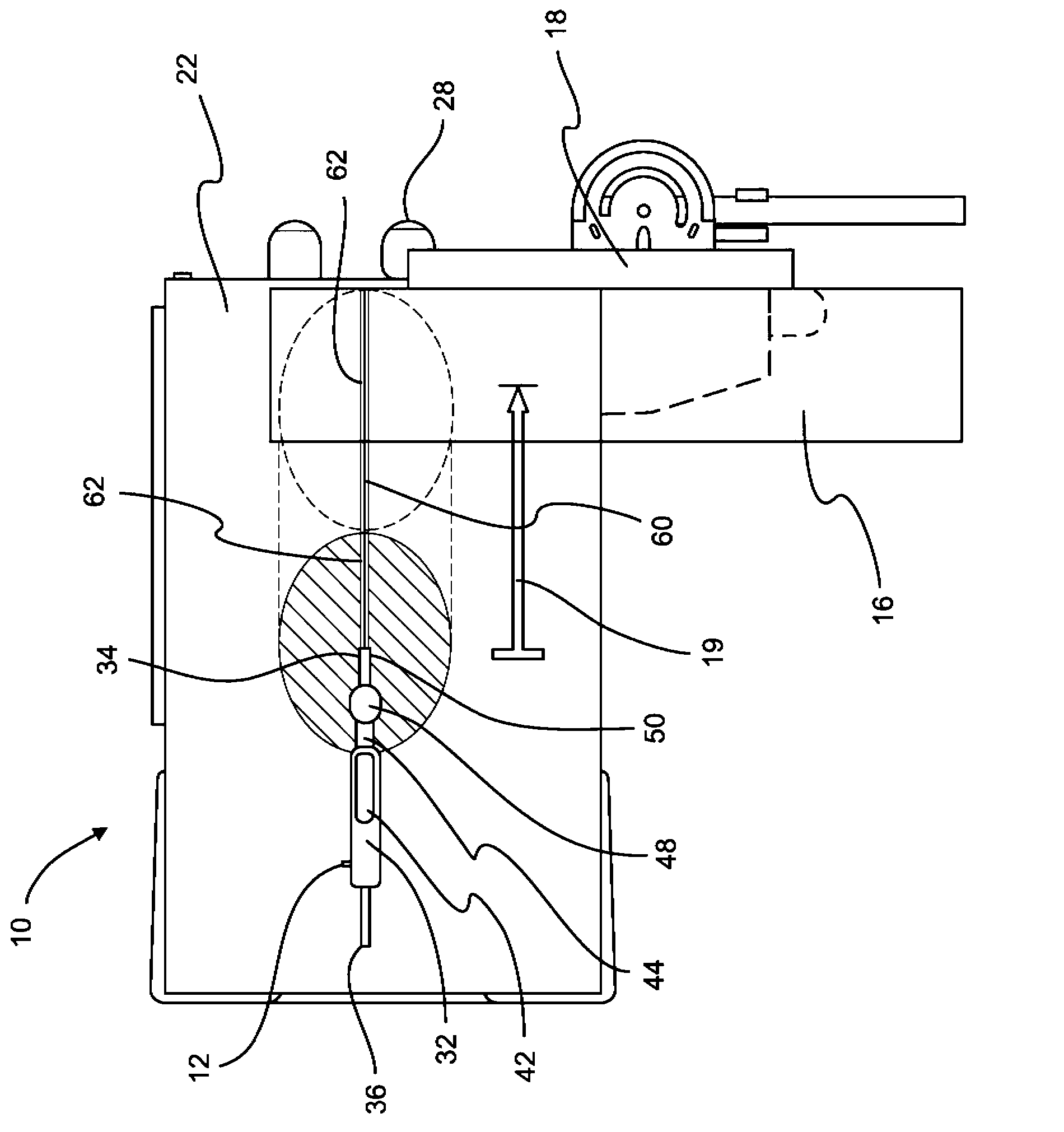

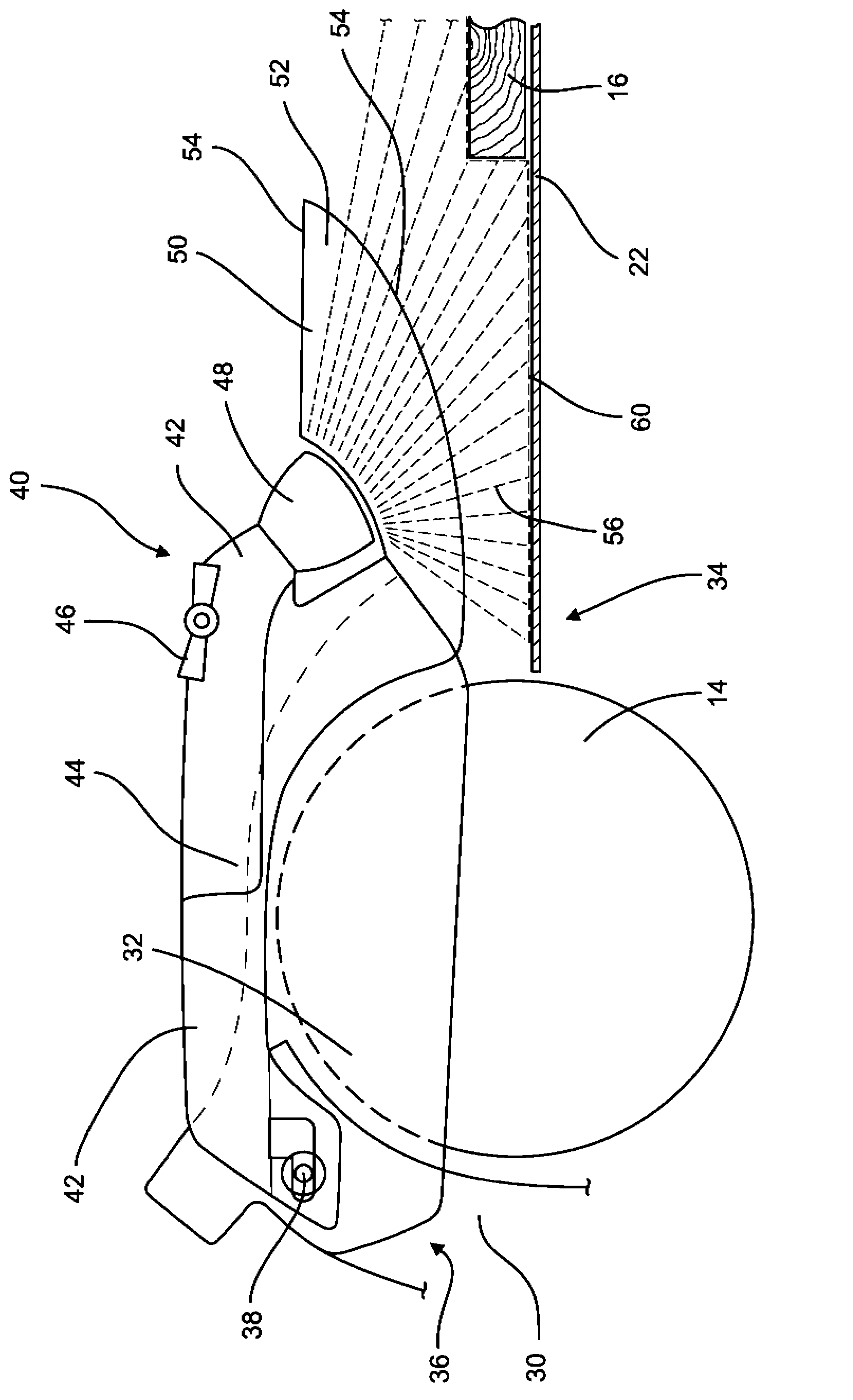

[0023] See in general Figure 1-3 , Shows an embodiment of a power tool with a light guiding and aligning device. The power tool is shown in the form of a table saw 10 including a saw 12 with a circular saw blade 14. The alignment assembly 40 with the light guiding device 50 is mounted to the front side of the saw 12. The light guiding device 50 is configured to guide the light beam from the light source 48 to a position in front of the circular saw blade and to provide a kerf mark 60 for the circular saw blade.

[0024] Those skilled in the art can recognize that the table saw 10 may include a movable bracket (not shown) that is coupled to the underside of the table top 22. The stand holds the saw 12 so that the circular saw blade 14 extends through the opening 24 formed in the table top 22. The opening 24 in the table top 40 is generally provided in the form of an elongated slit, thereby allowing the saw blade 14 to move along the table top 22 in a linear direction. The circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com