torque transmission device

A technology of torque transmission device and connection device, applied in the direction of coupling, ball bearing, rigid bracket of bearing parts, etc., can solve the problems of uneven loading of balls, increased manufacturing cost, overload, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

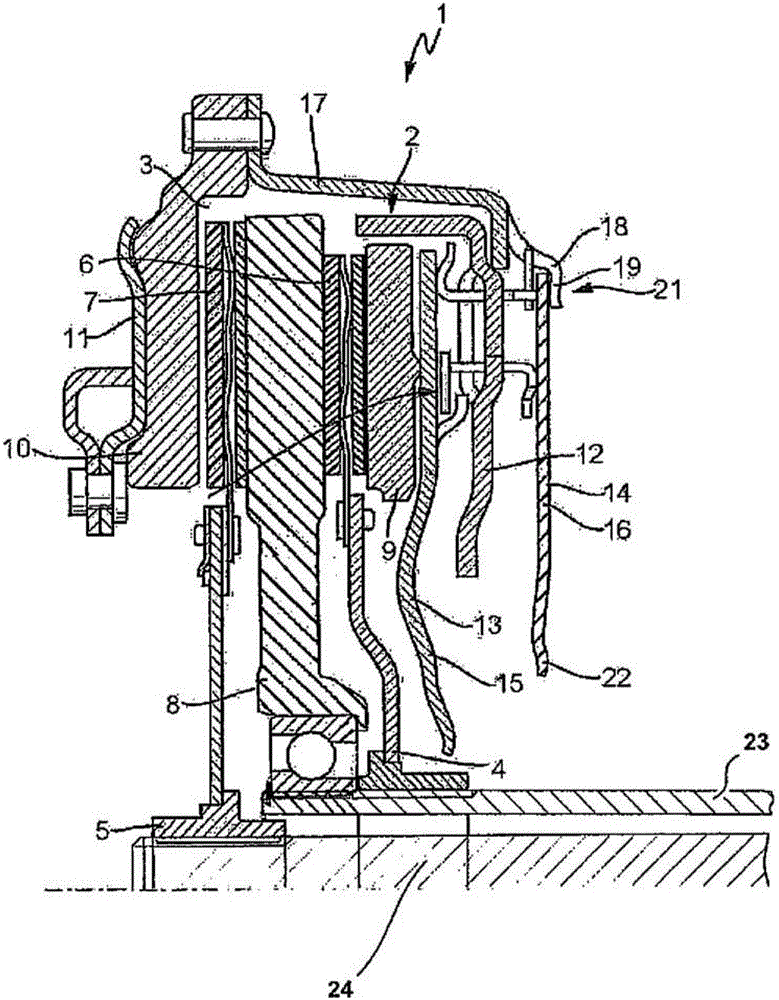

[0024] figure 1 The clutch assembly 1 shown in the figure comprises two friction clutches 2 , 3 which are shown in a disengaged state, ie in an open state. The clutch assembly 1 is part of the drive train of a motor vehicle, tractors, work machines, trucks, passenger cars and the like being understood by motor vehicles. The drive train connects the internal combustion engine to the driven wheels and includes, in addition to the clutch assembly, a parallel transmission and further transmission mechanisms such as shafts, differentials, and the like. The clutch assembly thus forms a double clutch comprising two clutch disks 4 , 5 which can be connected to different transmission input shafts.

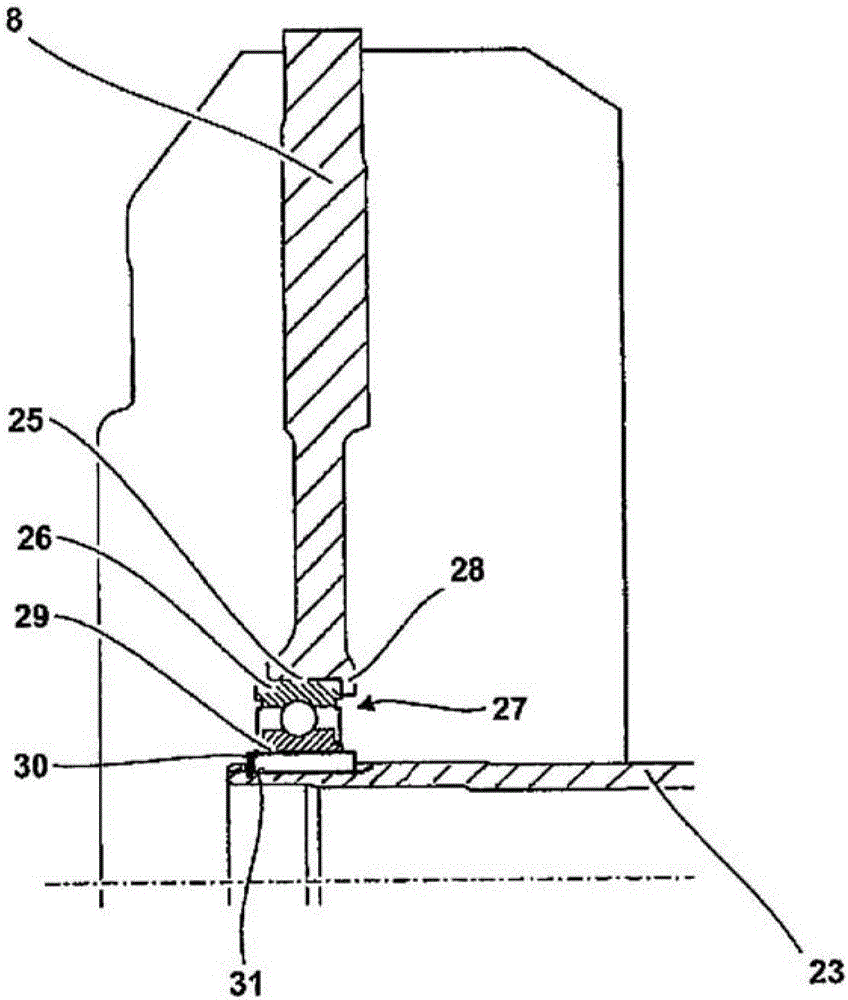

[0025] The clutch disks 4 , 5 carry friction disks 6 , 7 radially on the outside, which can be clamped axially on the counter pressure disk 8 common to the two friction clutches 2 and 3 and which are assigned to the respective friction clutch 2 or 3 between the compression plates 9,10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com