football

A technology of rugby and bladder, applied in the direction of balls, solid balls, sports accessories, etc., can solve the problems of weakened ball control, hard rugby, impact injuries of athletes, etc., and achieve excellent functional results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Combine below figure 1 , figure 2 , image 3 -5 further describe in detail the specific implementation of the present invention;

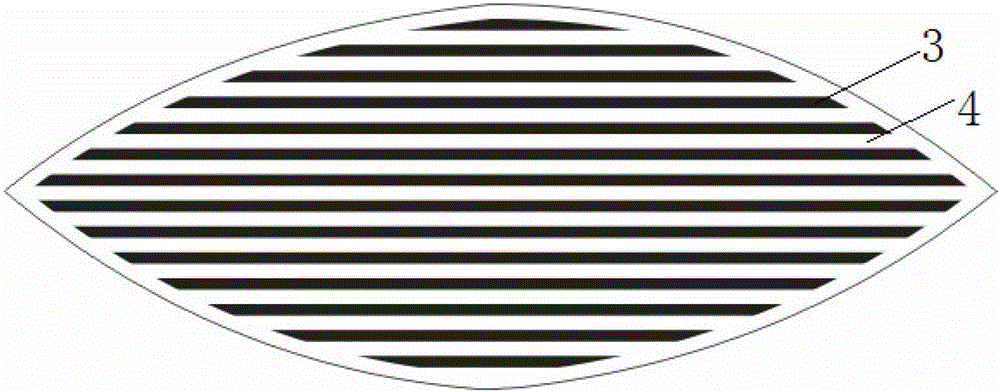

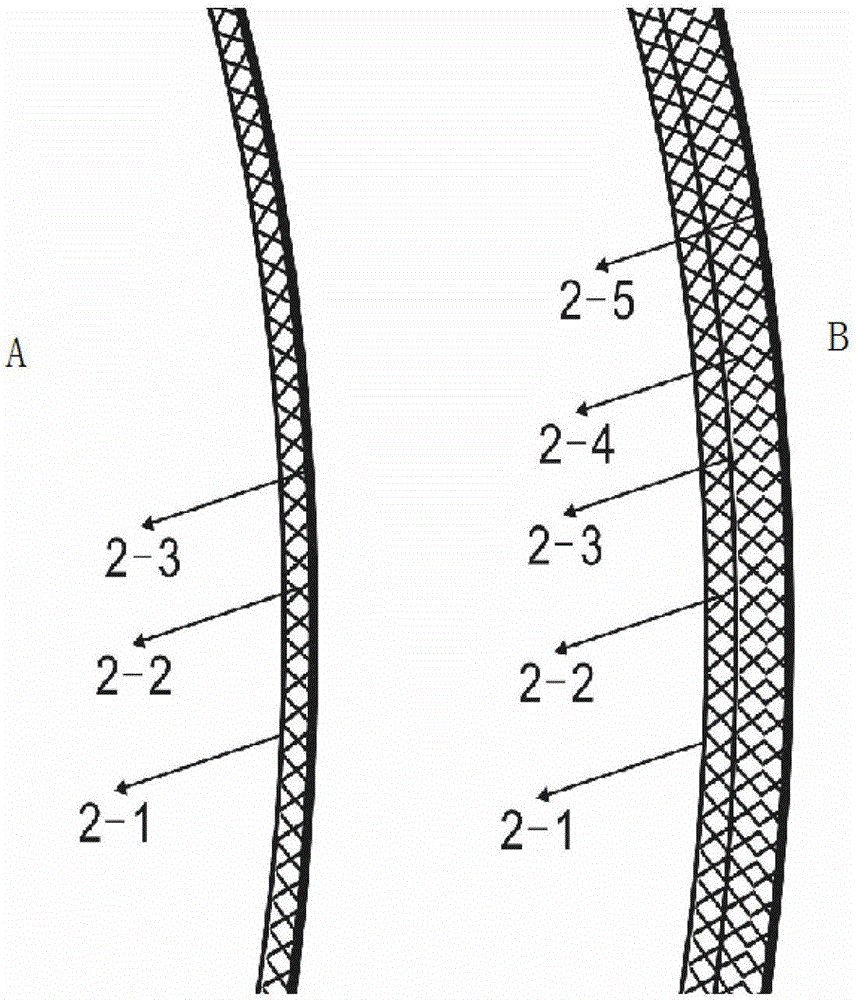

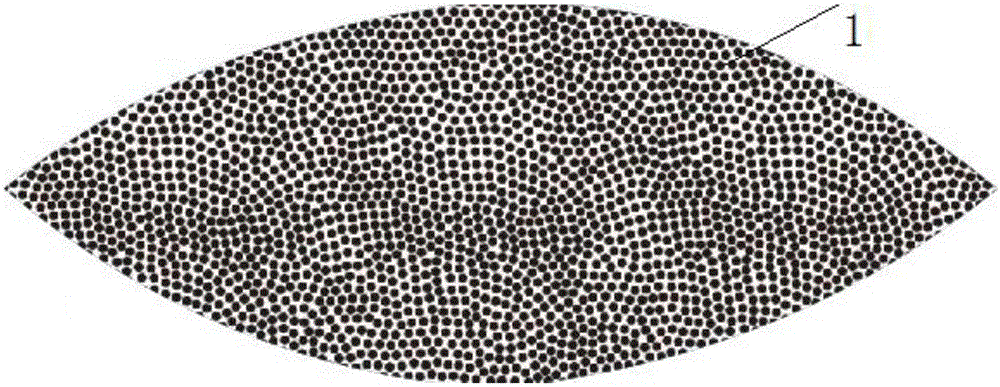

[0032] The U-shaped air groove or the air layer lining is pressed by a mold machine at high temperature. The U-shaped air groove or the air layer is irregular in shape, such as Figure 5 It can include the combination of dots, long grooves and short grooves, or the distribution of irregular polygons not shown in the figure. exist figure 1 Under the condition of the size of the area, more than one piece and less than 20 pieces can be adjusted in a single piece of reinforced lining, such as 15 or 13 pieces. The method of U-shaped air groove or air layer reinforced lining is. There is a liner that is figure 1 , image 3 The structure of -5, in the figure 1 is the skin layer, 3 is the sunken U-shaped air groove or air layer, and 4 is the rubber or foamed flat layer. The shapes of the depressed U-shaped air groove or air layer and the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com