Device and method for internal high pressure forming of pipe

A technology of internal high-pressure forming and pipe material, which is applied in the field of internal high-pressure forming of pipe materials, can solve the problems of bulky supercharger, low work efficiency, and complex system, and achieve the effects of saving ultra-high pressure pipelines, saving costs, and increasing dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

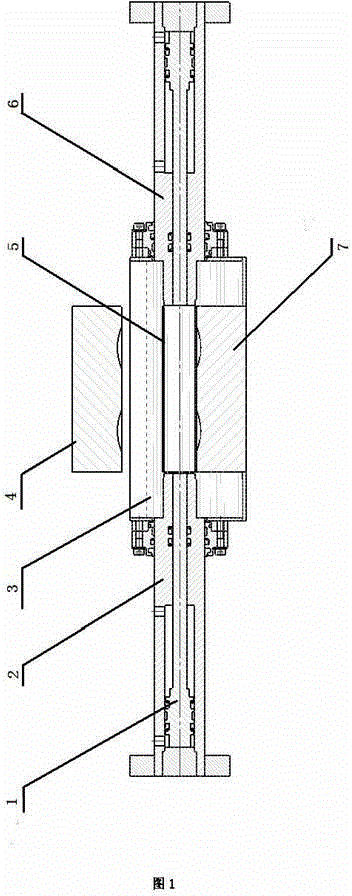

[0014] Such as figure 1 As shown, the pipe internal high pressure forming device of the present invention includes a booster rod 1, which is symmetrically arranged on the left and right. 2, 6 are in contact with the end surface of the hollow pipe 5 to form a sealed cavity; the high pressure forming device for the pipe also includes an upper mold 4 and a lower mold 7 for making the pipe 5 into a desired shape. The forming device also includes a water tank 3 into which liquid is injected, and the pipe material 5 is completely immersed in the liquid in the water tank 3 . The left and right push heads 2, 6 form a dynamic sealing connection with the wall of the water tank 3, so that the push heads 2, 6 can freely perform piston movements relative to the wall of the water tank 3 without leaking the liquid in the water tank 3.

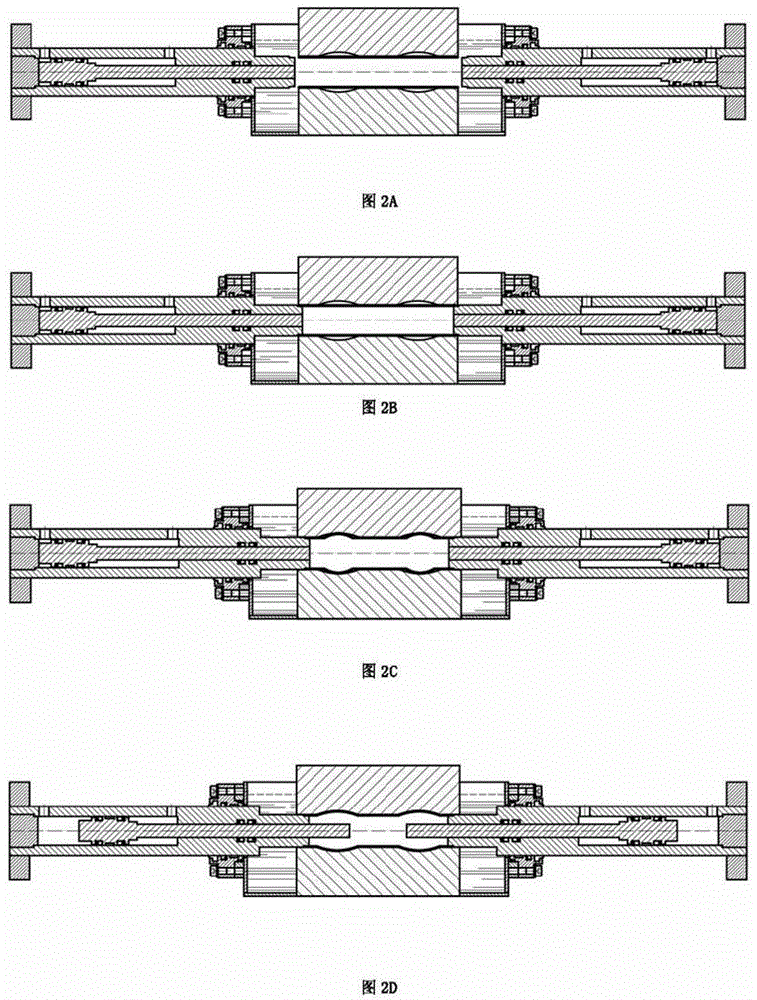

[0015] The high-pressure forming method in the pipe of the present invention is as follows: the pipe 5 is put into the cavity of the lower mold 7 in the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com