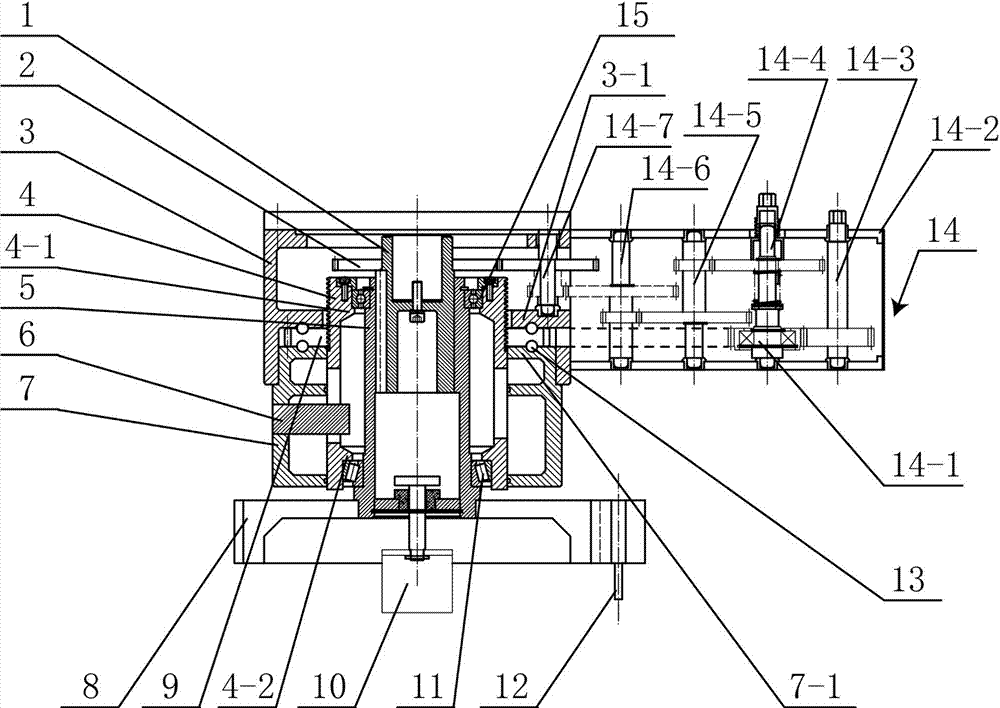

Cutter head feeding and retraction transmission control mechanism of emergency rescue fast anti-explosion tapping equipment

A feed control and transmission control technology, applied in drilling/drilling equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as easy delay in saving time, inability to open holes normally, affecting work efficiency, etc. The effect of vertical movement of the tool, flexible and convenient application, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] Such as figure 1 Shown, the present invention comprises driving shaft 1, and the lower end is fixedly connected with the cylindrical cutterhead sleeve 5 of cutterhead 8, and cutterhead 8 and cutterhead sleeve 5 are coaxially arranged and and cutterhead 8 has inner diameter and cutterhead sleeve Barrel 5 has substantially the same central through hole. The drive shaft 1 penetrates into the cutter sleeve 5 from the upper port of the cutter sleeve 5 and is connected with the cutter sleeve 5 through a flat key. 1, the keyway of the flat key is axially opened on the inner wall of the cutter head sleeve 5. Three cutters 12 are evenly distributed at 120° on the outer edge of the cutter head 8 . The drive shaft 1 drives the cutterhead 8 to rotate through the cutterhead sleeve 5, and the cutter 12 installed on the cutterhead 8 is used to implement the boring of the ship pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com