Rapid anti-explosion trepanning method for emergency salvation of turnover ship in danger

A technology of turning over and turning ships, which is applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc. Flexible and convenient, reduce the effect of feeding power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

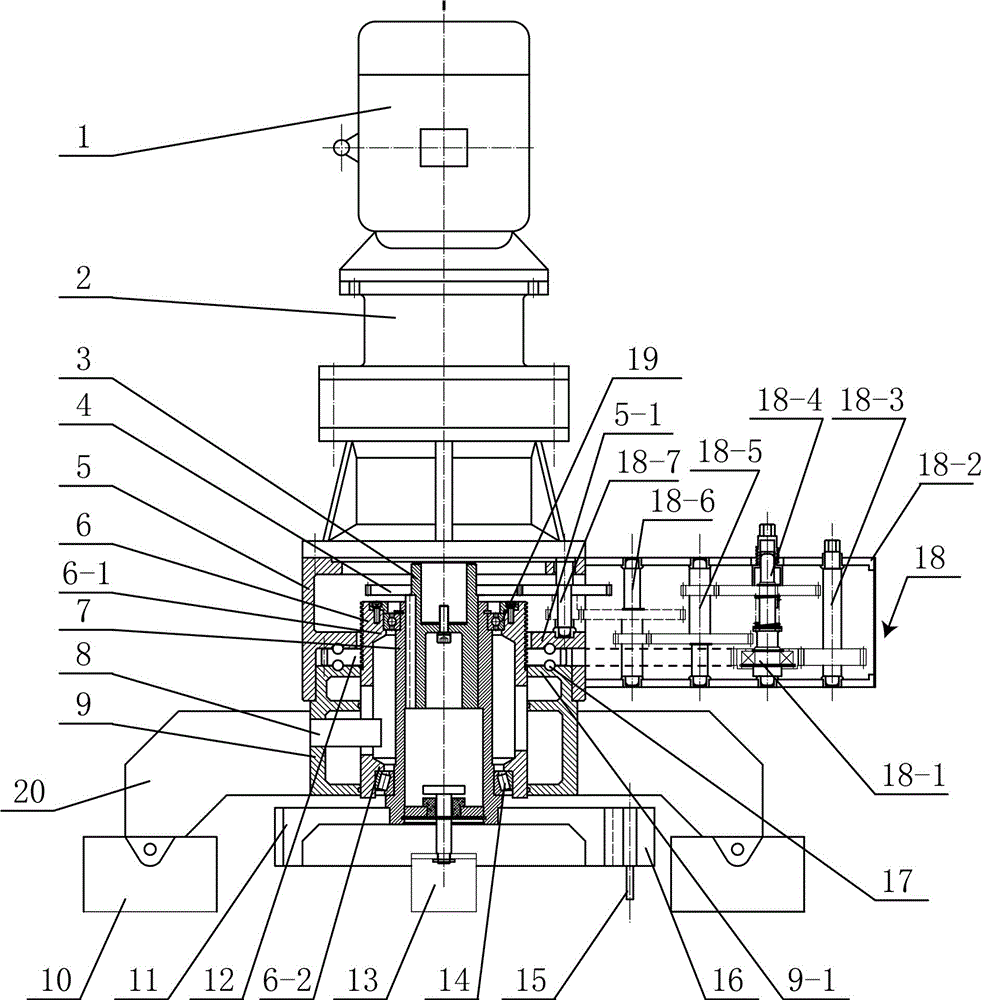

[0021] The present invention grasps the two core points of explosion-proof and non-sparking and rapid hole opening. Using high-throughput magnetic components, it can be quickly fixed to the surface of the ship's hull to ensure that the moderate swing of the ship in distress does not affect the operation of the equipment. The invention introduces a boring processing method to realize the cold cutting of the ship bottom plate without generating sparks, and only a small amount of seawater is used for cooling the cutting edge of the cutter. By adopting the mechanical differential automatic knife feed system, the fast feed cutting and opening are realized. The alloy high-speed steel is used to process special tools to ensure the strength of the tools; the innovation of 3-tool boring technology and the realization of different functions of the tools ensure fast and stable cutting and opening. Field experiments show that it takes about 10 minutes to cut a 460mm diameter hole on a 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com