Plate holding device with horizontal adjustment jig and method for adjusting the arrangement of plates

A technology of level adjustment and holding device, applied in the direction of positioning device, clamping, manufacturing tools, etc., can solve the problem of time-consuming board, and achieve the effect of preventing loss and easy angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

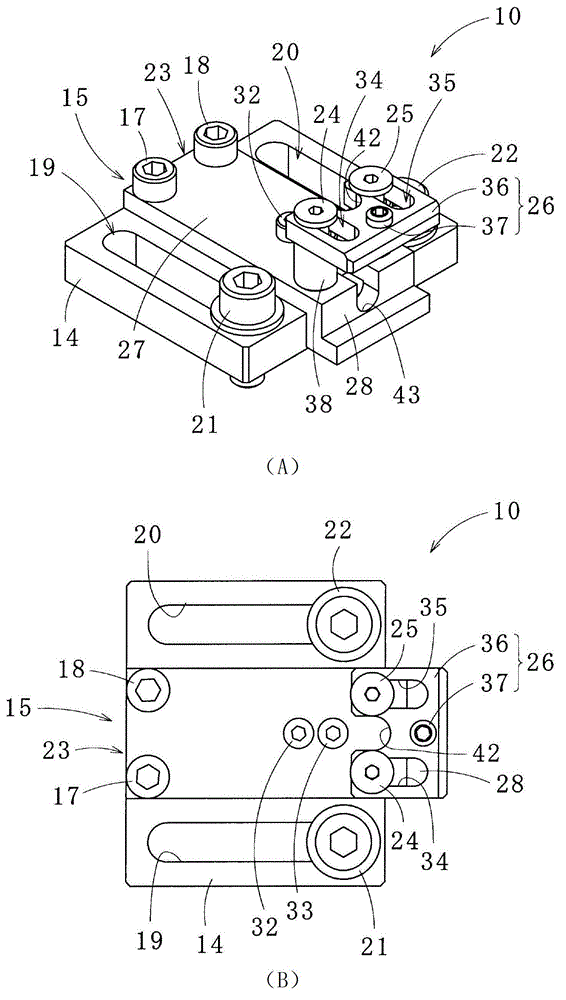

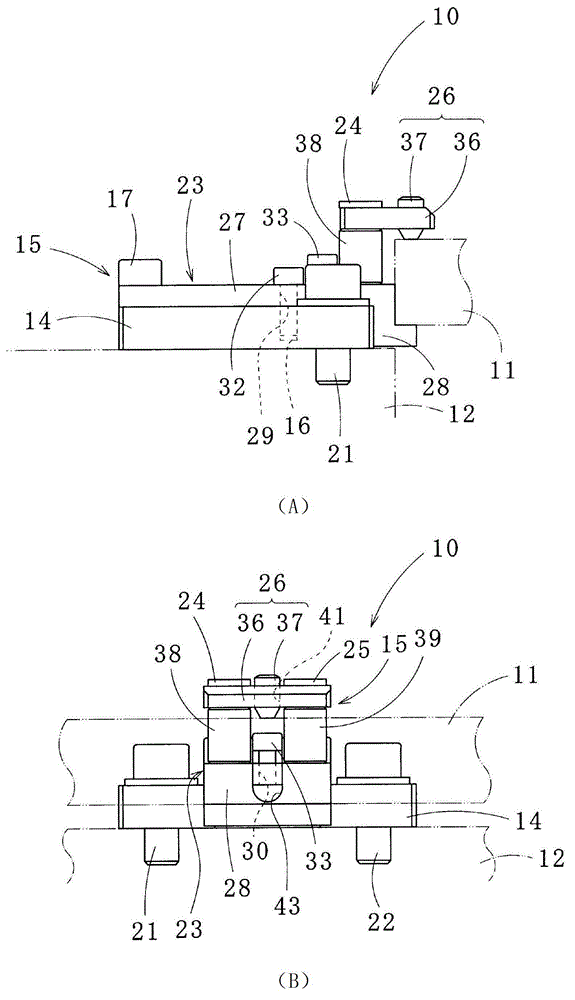

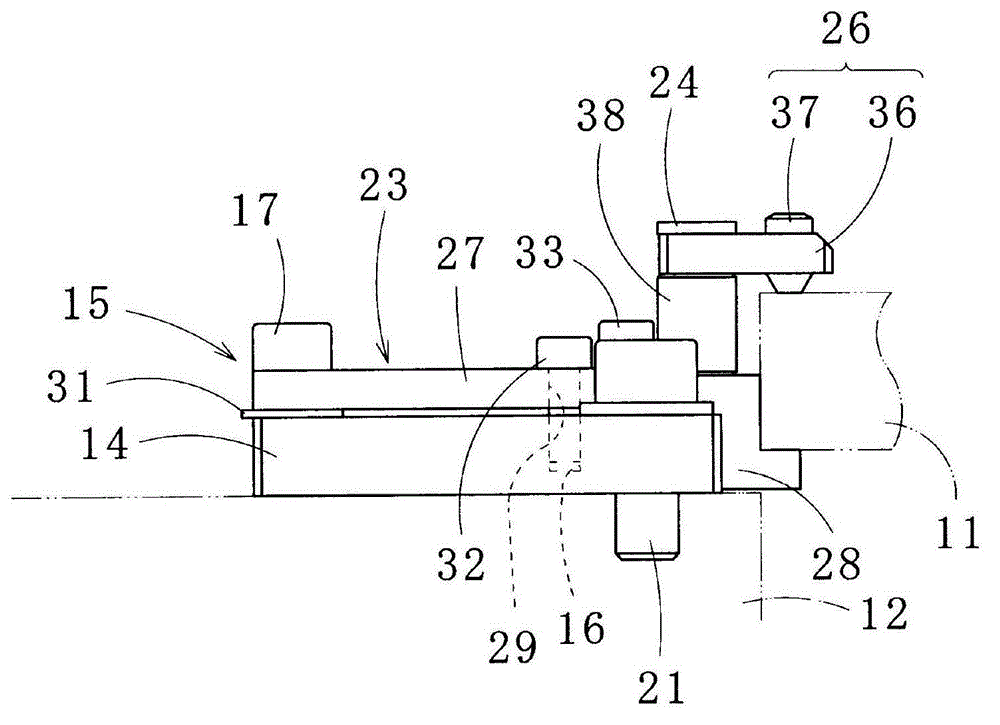

[0025] Next, specific embodiments of the present invention will be described with reference to the accompanying drawings for understanding of the present invention.

[0026] like figure 1 , figure 2 , Figure 5 As shown, a leveling jig 10 according to an embodiment of the present invention is used to fix a plate 11 on a support table 12 , and the leveling jig 10 has a base member 14 fixed on the support table 12 and a holder for clamping the plate 11 . Part 15.

[0027] Hereinafter, a detailed description will be given.

[0028] like figure 1 (A), (B) and figure 2 As shown in (A) and (B), the leveling jig 10 includes: a plate-shaped base member 14 in which a screw hole 16 (threaded hole A) is formed; the holding member 15.

[0029] The base member 14 is rectangular in plan view, and has longitudinal through holes 19 and 20 formed on its left and right sides, respectively, and is fixed to the support base 12 by a screw 21 inserted through the through hole 19 and a scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com