a velvet tube

A down-filling tube and body technology, applied in the field of down-filling tubes, can solve the problems of affecting the working environment, heavy labor for operators, waste of down and other issues, and achieve the effects of reducing labor intensity, improving the working environment, and avoiding spillage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

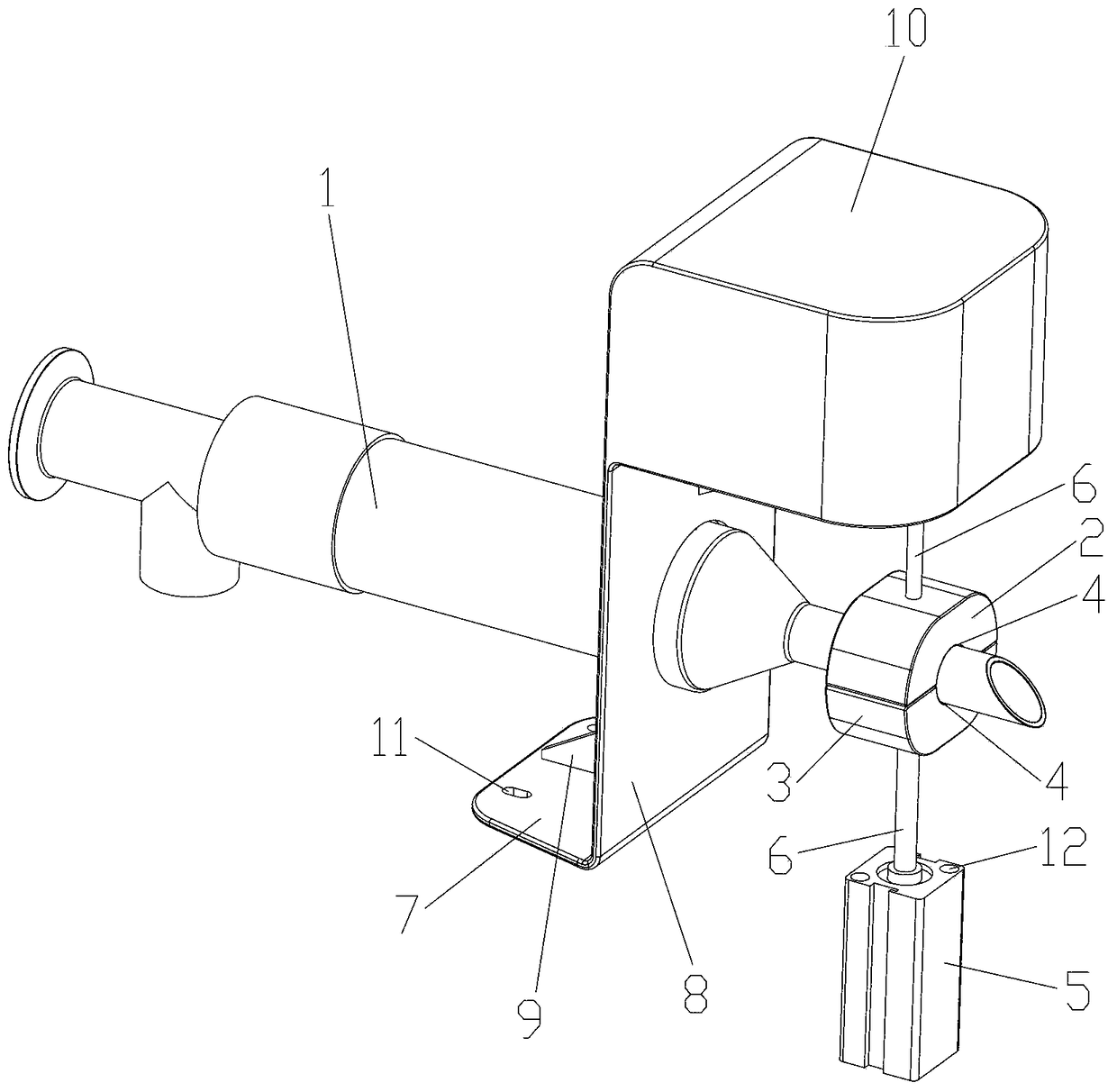

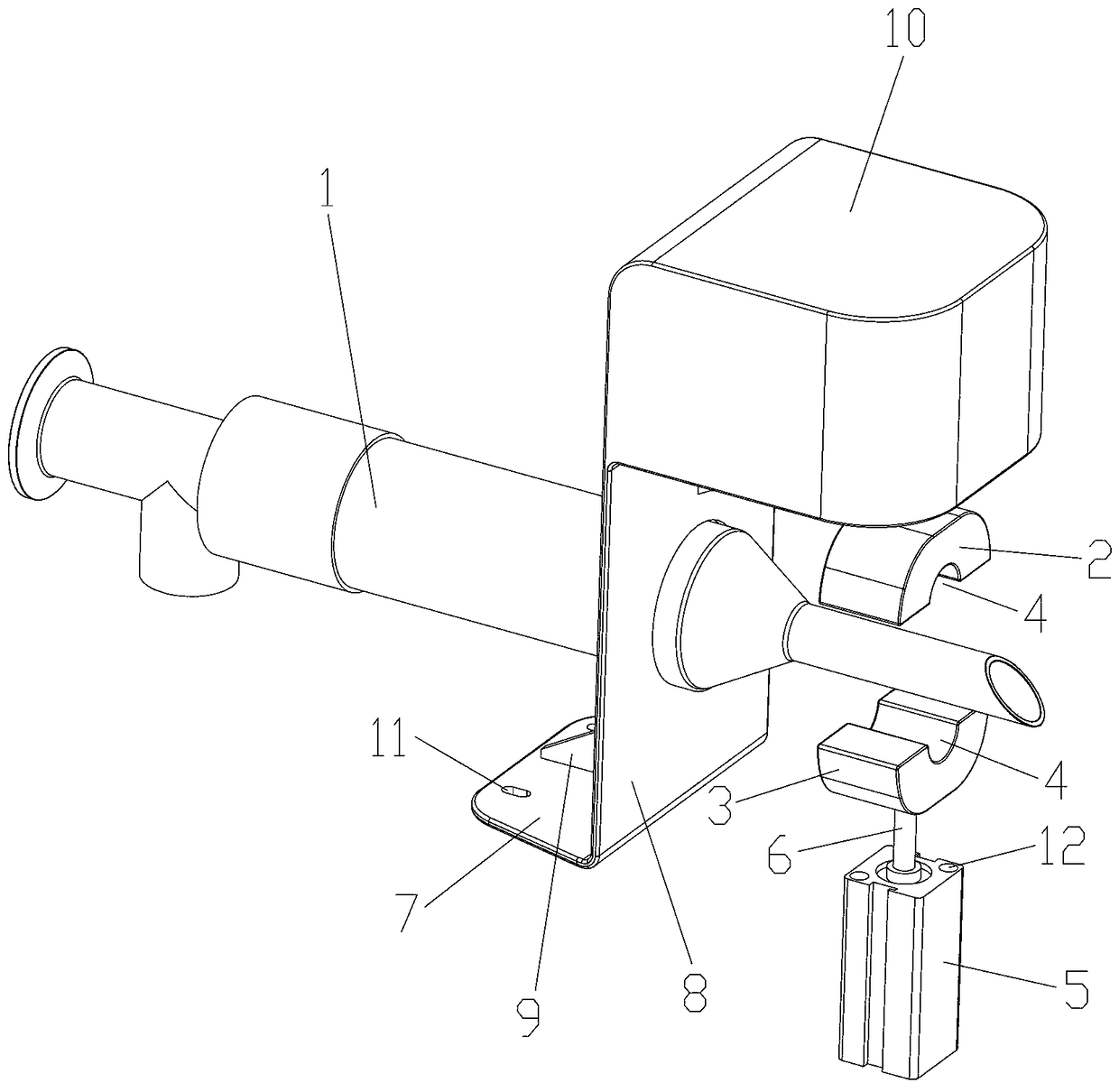

[0021] The present invention is described below in conjunction with accompanying drawing.

[0022] as attached figure 1 The shown down-filling tube of the present invention includes a down-filling tube body 1, and the front end of the down-filling tube body 1 is provided with a locking clip device; the locking clip device includes an upper clamping block 2, a lower clip Clamping block 3 and the driving device that controls the movement of upper clamping block 2 and lower clamping block 3; the lower surface of the upper clamping block 2 and the upper surface of the lower clamping block 3 have a Matching semicircular groove 4; when the upper clamping block 2 and the lower clamping block 3 are spliced, the front end of the down filling tube body 1 passes through the circular groove formed by the two semicircular grooves 4; the driving device is an upper Cylinder (not shown in the figure) and lower cylinder 5; The telescoping rod 6 of described upper cylinder, lower cylinder 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com