Cleaning vehicle for full section of tunnel

A full-section, clean vehicle technology, applied in road cleaning, cleaning methods, construction, etc., can solve the problems of complex equipment damage and damage, and achieve the effect of reducing damage and damage and safe driving environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

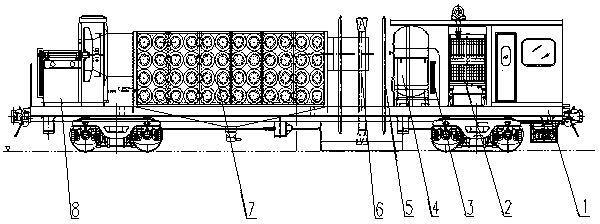

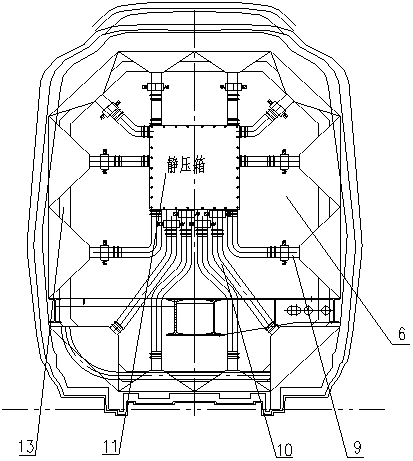

[0017] figure 1 Among them, a power unit 2 , an air compressor 3 , an air storage cylinder 4 , a dust blower 5 , a dust collector 6 , a dust filter 7 , and a fan 8 are arranged on the car body 1 . The power unit 2 is connected with the vehicle body 1 by bolts, which is firm and reliable, easy to disassemble, and provides alternating current for the whole vehicle. The air compressor 3 blows the air to the air storage cylinder 4 to provide a high-pressure air source for the dust blowing nozzle 12 .

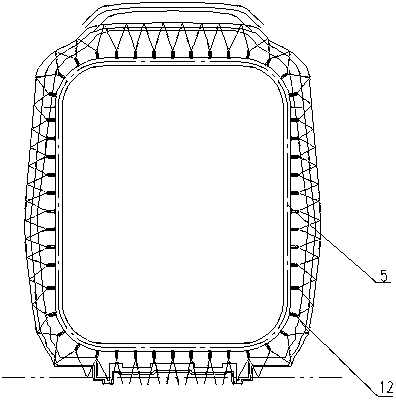

[0018] There are two groups of dust blowing devices 5 arranged in the middle of the vehicle frame. The 54 nozzles are evenly distributed. The two groups of dust blowing devices 5 are symmetrically arranged, and the corresponding group can be opened according to the driving direction of the vehicle. The dust collection device 6 is set between the two sets of dust blowing devices 5, and there are 12 sets of dust collection covers on the bracket 13, which are connected to the static p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com