Vacuum heat collecting element with straight cylinder decompression air drying protector

A heat-collecting element and vacuum heat-collecting technology, applied in heating devices, solar thermal devices, solar thermal power generation, etc., can solve the problem of reduced ability to restore the original state, poor pertinence, and consistency of bimetal thermal energy conversion drive parts not good and other problems, to achieve the effect of cost saving, reliability improvement, and heat dissipation power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

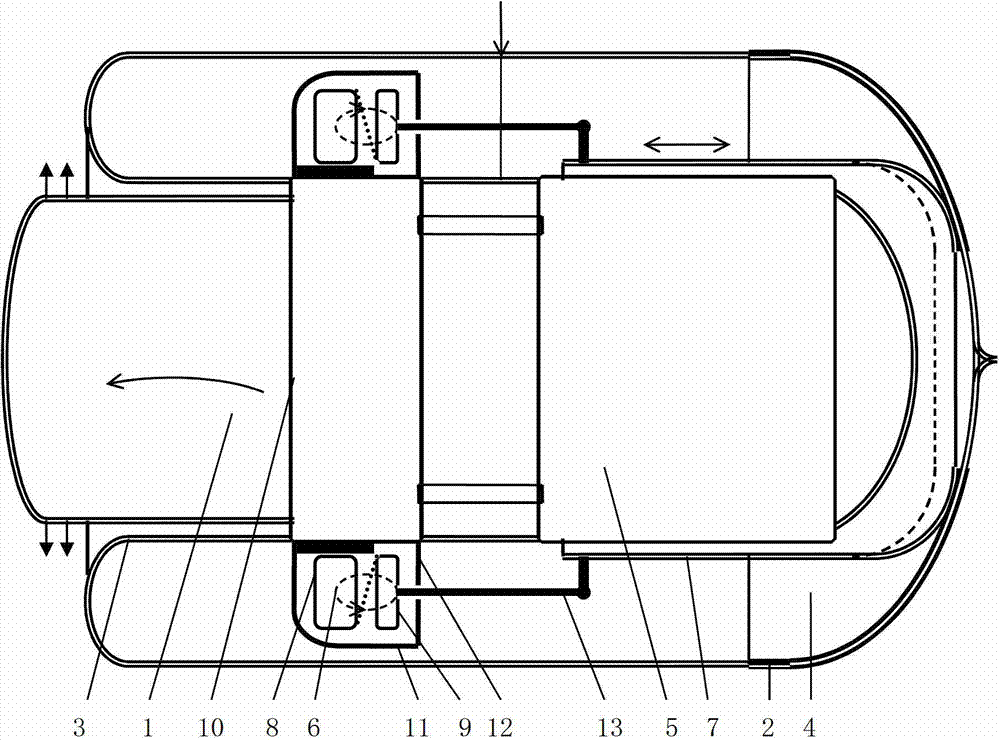

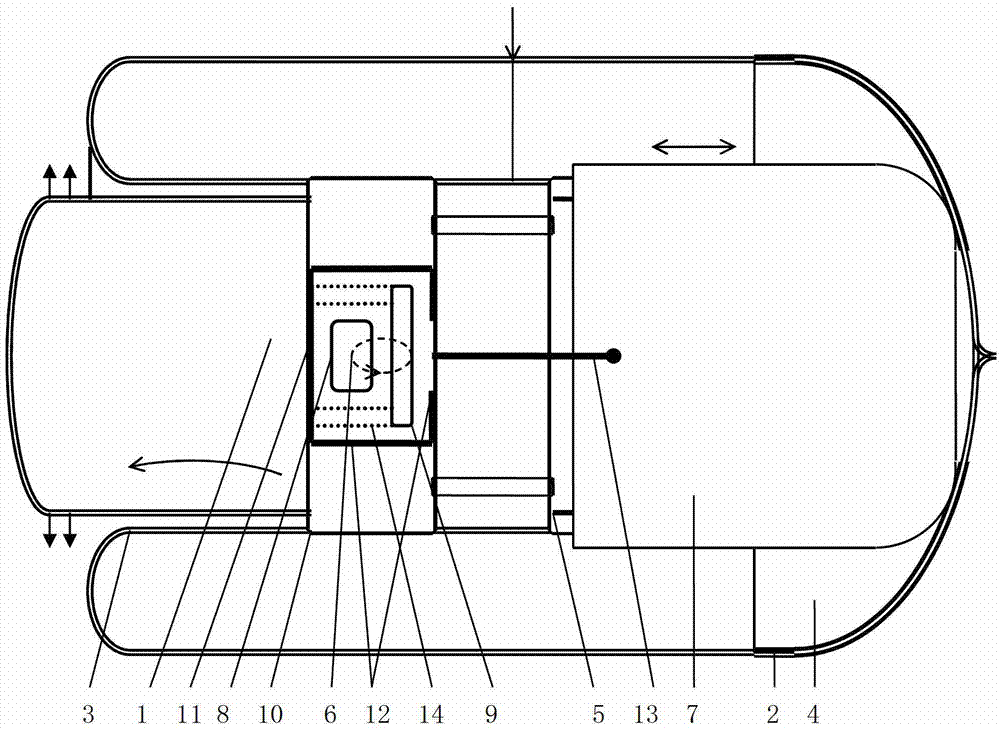

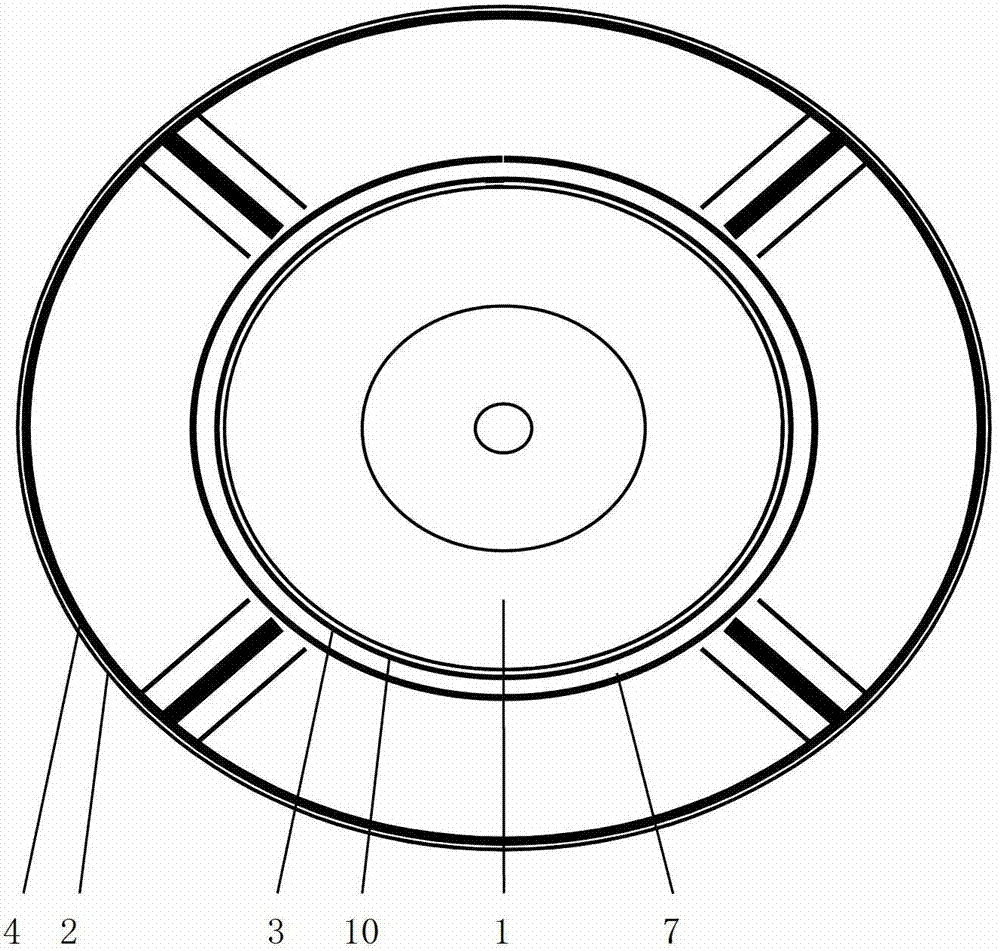

[0029] figure 1 , figure 2 and image 3 An example of the present invention is given.

[0030] Figures 1 to 3 Among them, in the vacuum heat insulation layer between the tail end of the glass tube 2 and the tail end of the inner glass tube 3 of an all-glass vacuum heat collecting tube, a straight cylinder decompression air protector is set to form a straight cylinder decompression air The vacuum heat collecting element of the sun protector. The straight tube decompression air drying protector is composed of a heat dissipation patch 4, a heat sink 5, a heat-sensitive permanent magnetic steel driving device 6 and a heat transfer straight tube 7. The shape of the outer surface of the cooling patch 4 matches the shape of the inner surface of the tail end of the cover glass tube 2 . The heat dissipation patch 4 has a thickness of 0.22 mm and a width of 40 mm. The heat dissipation patch 4 is pressed and pasted on the inner wall of the cover glass tube 2 by a circlip. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com