Telephone receiver with improved transmission mechanism

An improved technology for receivers, applied in the direction of sensors, speaker screens, transducer shells/cabinets/brackets, etc., can solve the problems of increased volume of receivers, howling of receivers, increased production costs, etc., and achieve audio output improvement and offset Effect of axial vibration and vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

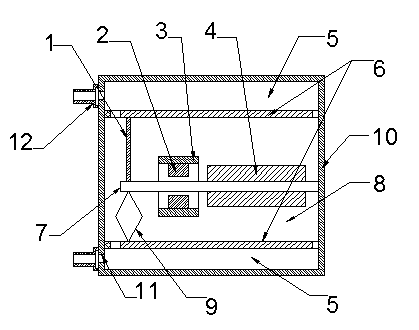

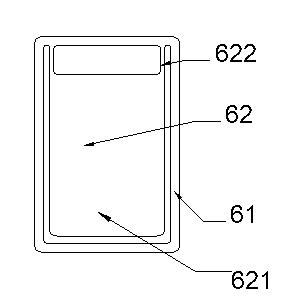

[0029] Such as Figure 1-3 As shown, a receiver with an improved transmission mechanism includes an electromagnetic shielding case 10, a diaphragm 6, an electromagnetic conversion mechanism and a power transmission mechanism, and the diaphragm 6 and the electromagnetic conversion mechanism are all arranged in the electromagnetic shielding case 10; wherein the electromagnetic conversion The mechanism includes an armature 7, and the diaphragm 6 is symmetrically arranged on the upper and lower sides of the electromagnetic conversion mechanism along the vibration direction of the armature 7, and is connected to the armature 7 through a power transmission mechanism. The power transmission mechanism includes a conductive rod 1 and a conductive ring 9. The diaphragm 6 on one side of the armature 7 is connected to the armature 7 through the conductive rod 1, and the diaphragm 6 on the other side of the armature 7 is connected to the armature 7 through the conductive ring 9. The armatu...

Embodiment 2

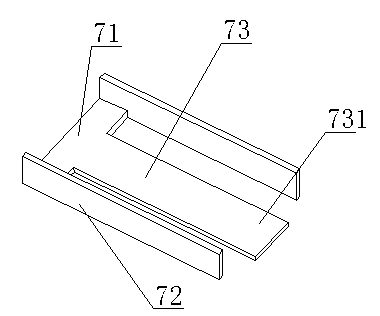

[0035] All the other are identical with embodiment 1, and difference is, as Figure 4As shown, the material of the conduction ring 9 is stainless steel, the conduction ring 9 is a circular ring, the armature 7 and the diaphragm 6 are fixedly connected to the axisymmetric ends of the circular ring respectively, and the conduction rod 1 and the armature 7 and the diaphragm 6 are fixedly connected. The connection is welding, and the connection between the conductive ring 9 and the armature 7 and the diaphragm 6 is also welding.

Embodiment 3

[0037] All the other are identical with embodiment 2, and difference is, as Figure 5 As shown, the conductive ring is an elliptical ring, and the armature 7 and the vibrating membrane 6 are fixedly connected to both ends of the major axis or both ends of the short axis of the elliptical ring, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com