Micro part clamping device

A technology of tiny parts and parts clamps, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of assembly difficulty and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

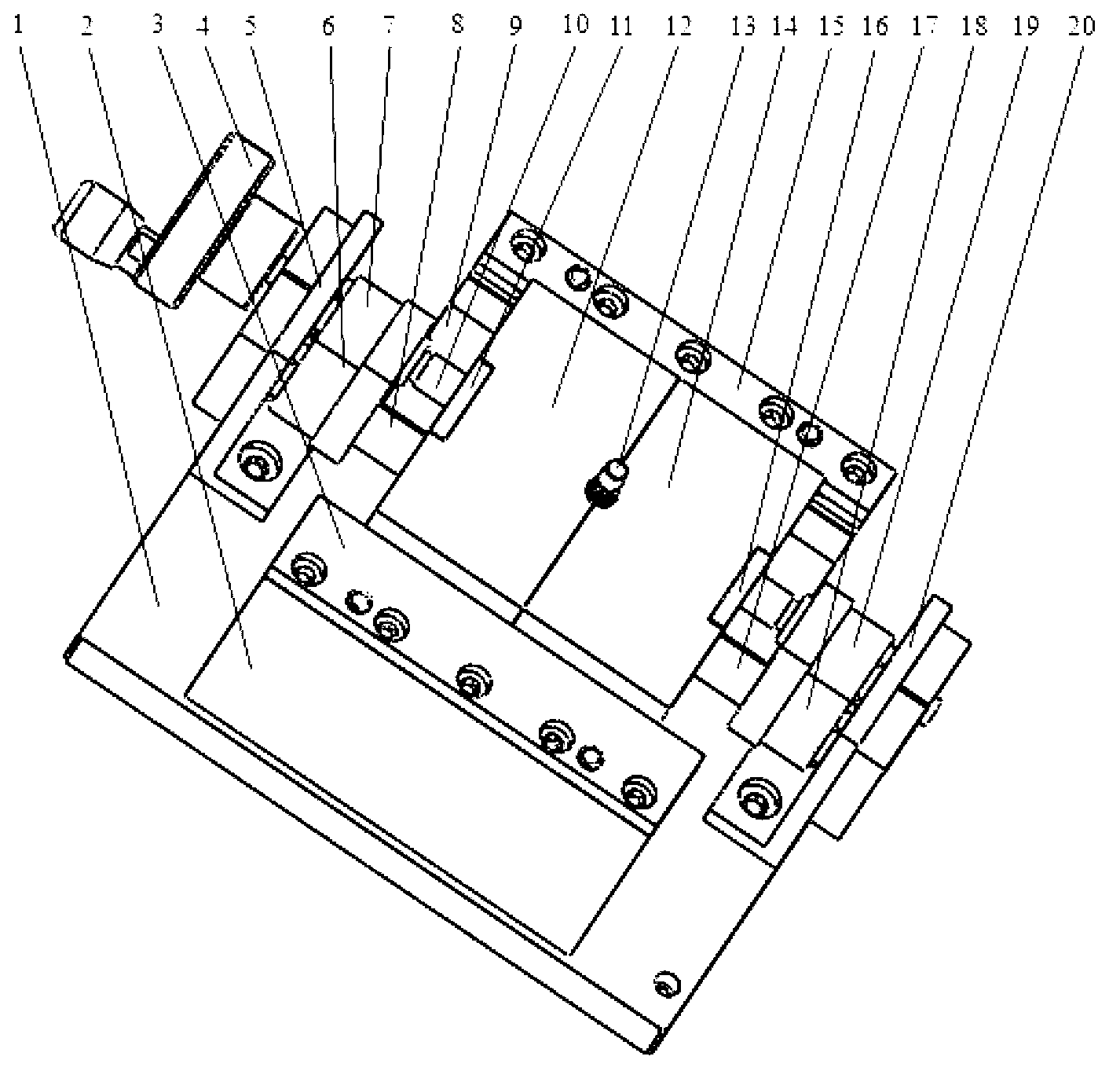

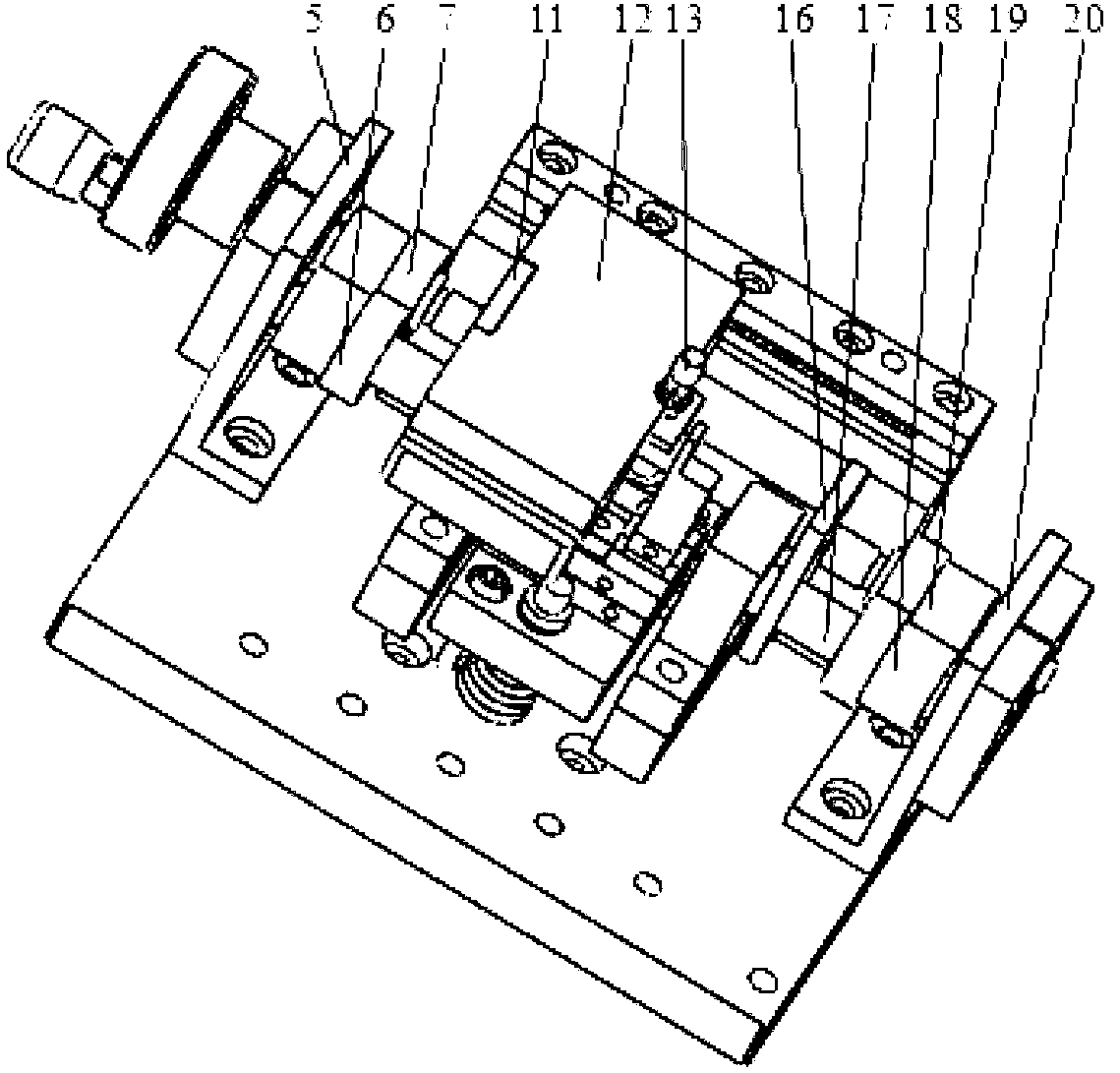

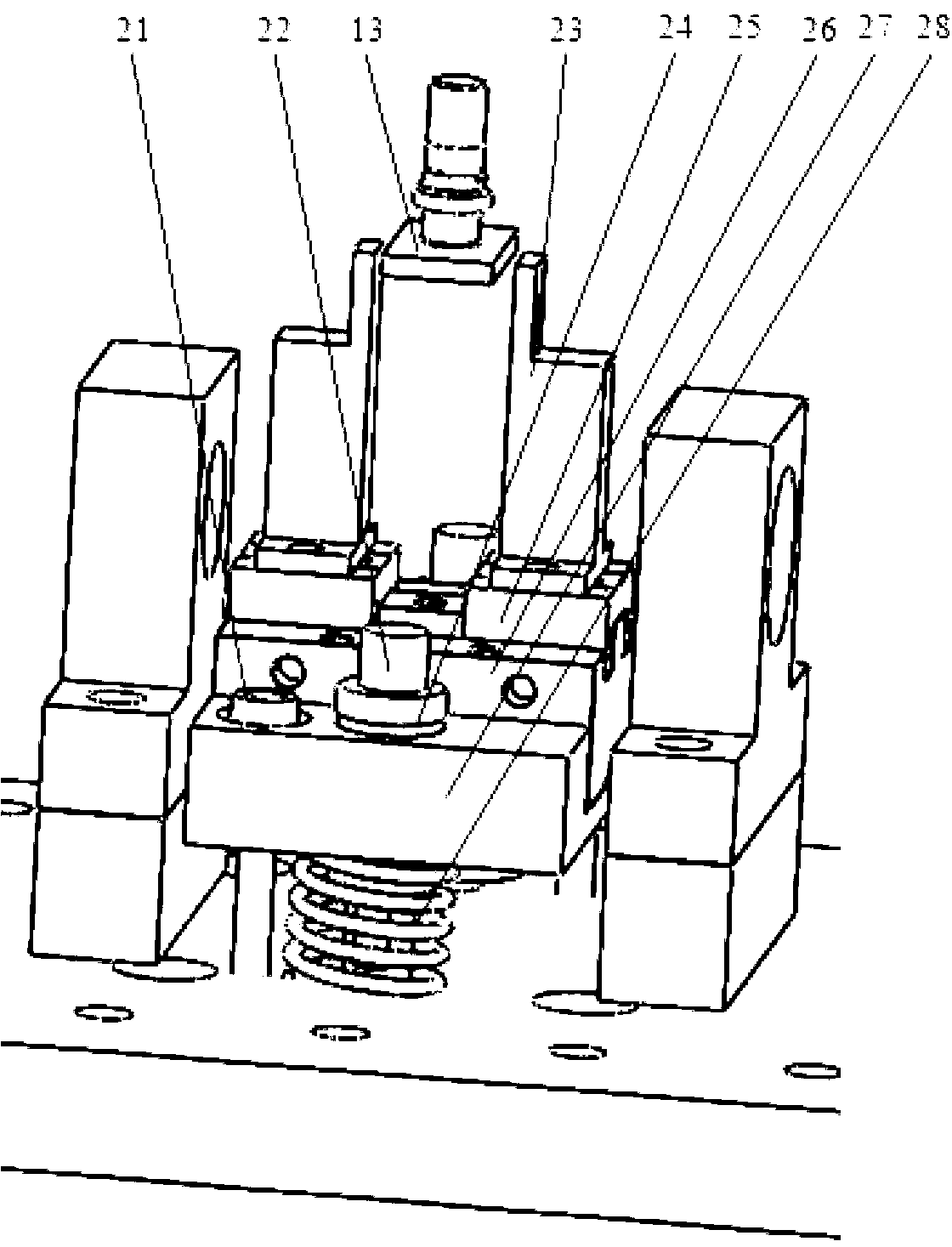

[0019] Left support 2, right support 9 and bearing support seat one 5 and bearing support seat two 20 are installed on the fixture installation base 1, and left cross plate 12 and right cross plate 14 are installed on the guide rail surface of left support 2 and right support 9.

[0020] By turning the hand wheel 4, the transmission shaft 10 is rotated, and the transmission shaft 10 transmits the motion to the screw rod 18 through the meshing of the gear 2 7 and the gear 1 6, and the screw rod 1 8 drives the stopper 11 through threaded cooperation, and the stopper 11 drives The left horizontal plate 12 fixed together with it moves; while the left horizontal plate moves, the drive shaft 10 transmits the motion to the screw 2 17 through the meshing of the gear 3 18 and the gear 4 19, and the screw 2 17 drives the stopper 2 through thread cooperation 16, stop block two 16 drives the right cross plate 14 movement that is fixed together with it, so just realized left cross plate 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com