Tool trolley

A technology of tool carts and boxes, which is applied in the direction of manufacturing tools, tool storage devices, trolleys, etc., can solve the problems of easy deformation, unfavorable recycling, and inconvenient maintenance, and achieve the goal of improving impact resistance, improving maintenance convenience, and practical maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

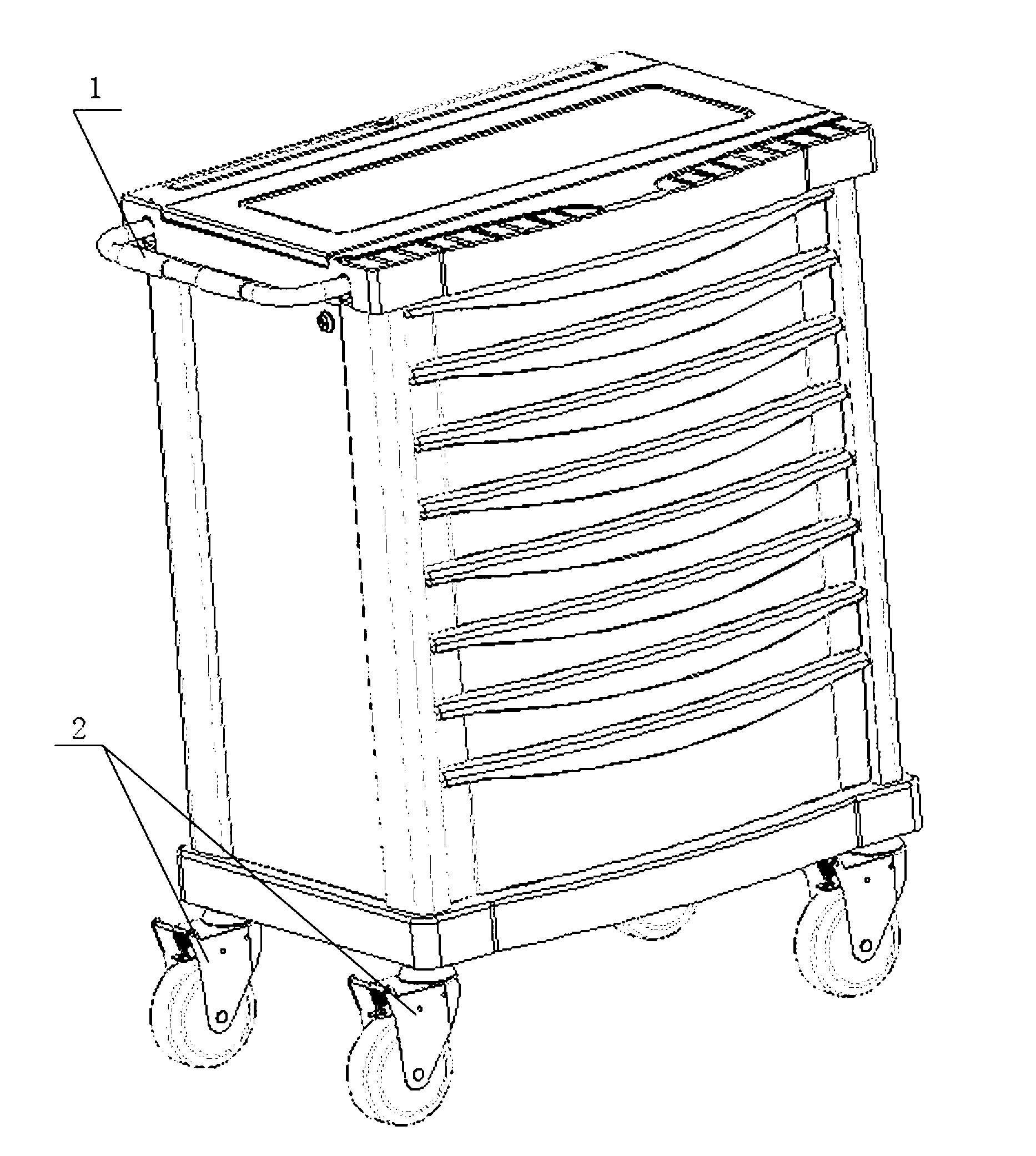

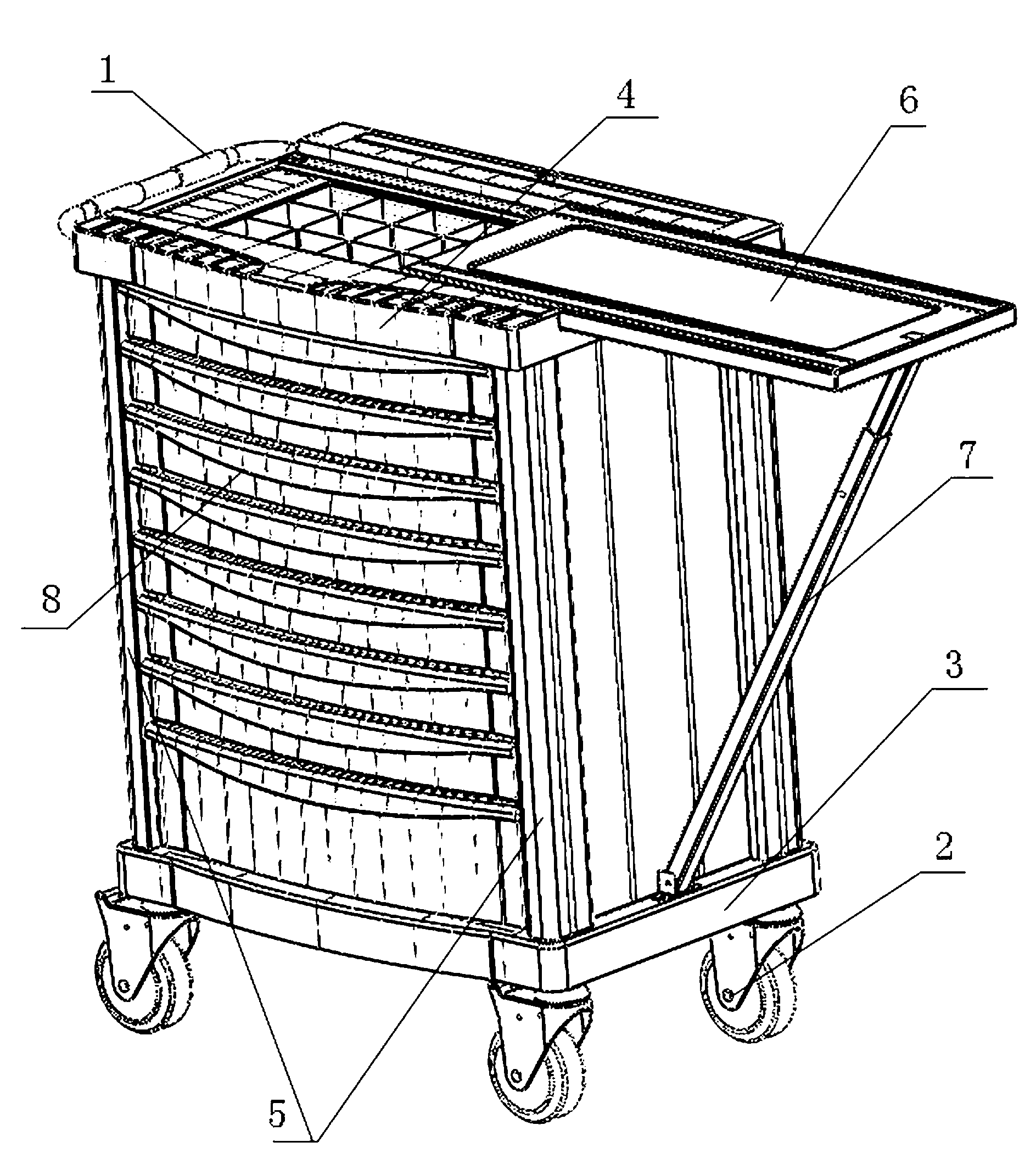

[0042] Such as Figure 1-7As shown, a tool cart includes a box body and casters 2, the box body is a quadrangular column, the casters 2 are installed on the four feet of the box body, and a handle 1 is provided on the box body, and the handle 1 is U-shaped structure, the upper end of the U-shaped structure is provided with a support shaft 1-1 on both vertical sides on the same plane, the handle 1 is installed on the box body through the support shaft 1-1, and the handle 1 can rotate around the support shaft 1-1. The upper and lower sides of the support shaft 1-1 are provided with limit blocks to prevent the handle from having no focus; the end of the U-shaped structure of the handle 1 is connected to the brake device on the caster 2 through a steel wire 10; the brake device is also a lever structure , fixed on the bracket of the caster 2 through the brake shaft 2-2, one end of the lever is fixedly connected to the bracket of the caster 2 through the spring 2-1, and the other e...

Embodiment 2

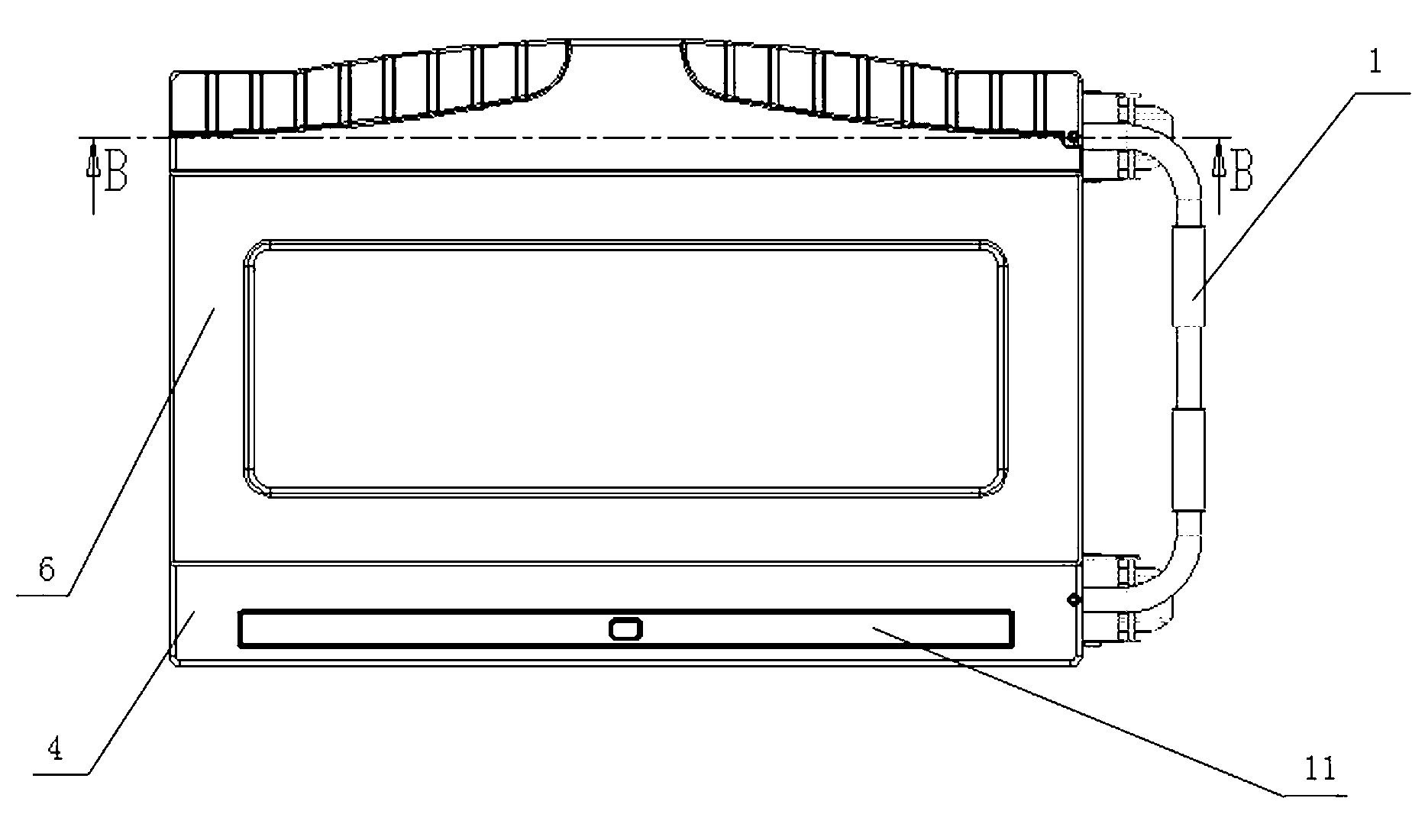

[0045] On the basis of Embodiment 1, the box body is a frame structure, which includes a base 3, a top cover 4, and the base 3 and the top cover 4 are fixedly connected by a column 5, and the fixed connection is bolted; the box The three sides of body are sealed by gusset plate, and casing interior is provided with a plurality of interlayers 9, and drawer 8 is placed on interlayer 9.

[0046] The beneficial effect of this embodiment is that: the frame-type easy-to-detachable tool cart facilitates inspection and maintenance as well as waste recovery and reuse.

Embodiment 3

[0048] On the basis of Example 2, the base 3, top cover 4, and column 5 protrude from the outside of the buckle plate and the drawer panel, and a plastic apron is set on the outside of the base 3 and the top cover 4.

[0049] The beneficial effects of this embodiment are: protecting the structure of the box body, avoiding scratches and bumps caused by direct contact between the box body and the outside world; and providing the impact resistance of the base 3 and the top cover 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com