Traction motor on-line monitoring-based electric locomotive idling slippage identification method

A traction motor and identification method technology, applied to locomotives, etc., can solve the problems of performance being easily affected by the working environment, reliability reduction, and the average adhesion coefficient of locomotives falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

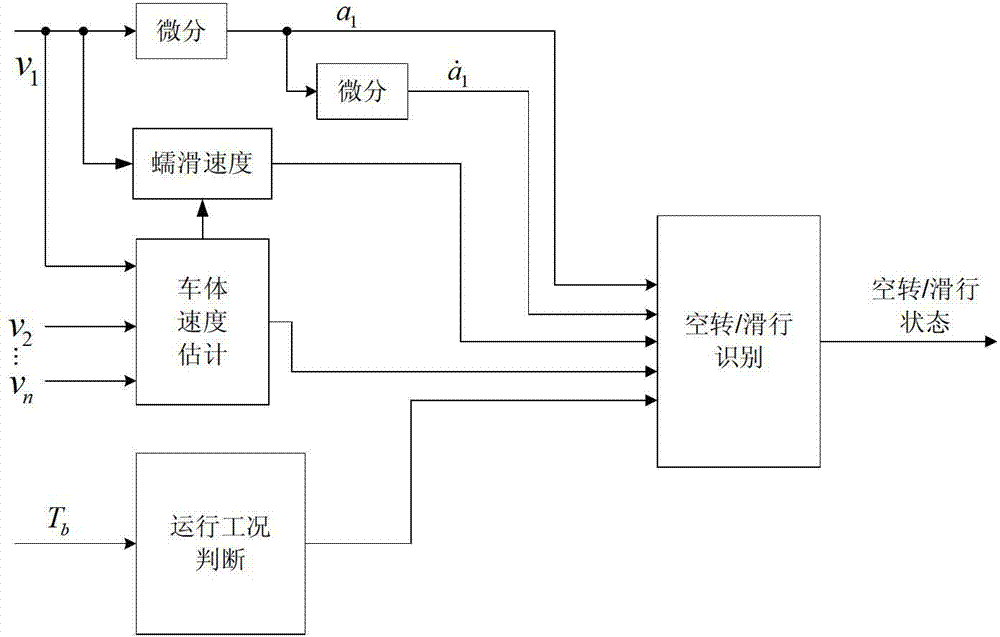

[0022] A method for idling / sliding identification of electric locomotives based on online monitoring of traction motors, such as Figure 4 shown, including the following steps:

[0023] Step 1. Online collection of electrical quantities

[0024] In this step, real-time monitoring data is obtained by online monitoring of relevant electrical quantity information, which provides a data basis for subsequent steps.

[0025] The specific method is as follows: the three-phase voltage u of the traction motors of each axle is collected online by the traction motor current and voltage sensors or the multi-function vehicle bus (MVB) of the locomotive ia , u ib , u ic ﹑Three-phase current i ia ,i ib ,i ic and traction torque command T b , where the subscript i=1,…n, n is the total number of axles of the locomotive.

[0026] Step 2. Establish a sixth-order motor model including load torque and motor speed as unknown quantities. Combined with the model, the multi-sampling rate exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com