Assembling external restraining precast pile with stiffening ribs and capable of preventing bending and shear damage

A shear failure, prefabricated pile technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve problems such as complicated situations, improve horizontal resistance, improve pile bearing capacity, and enhance pile bending resistance. The effect of the ability to cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

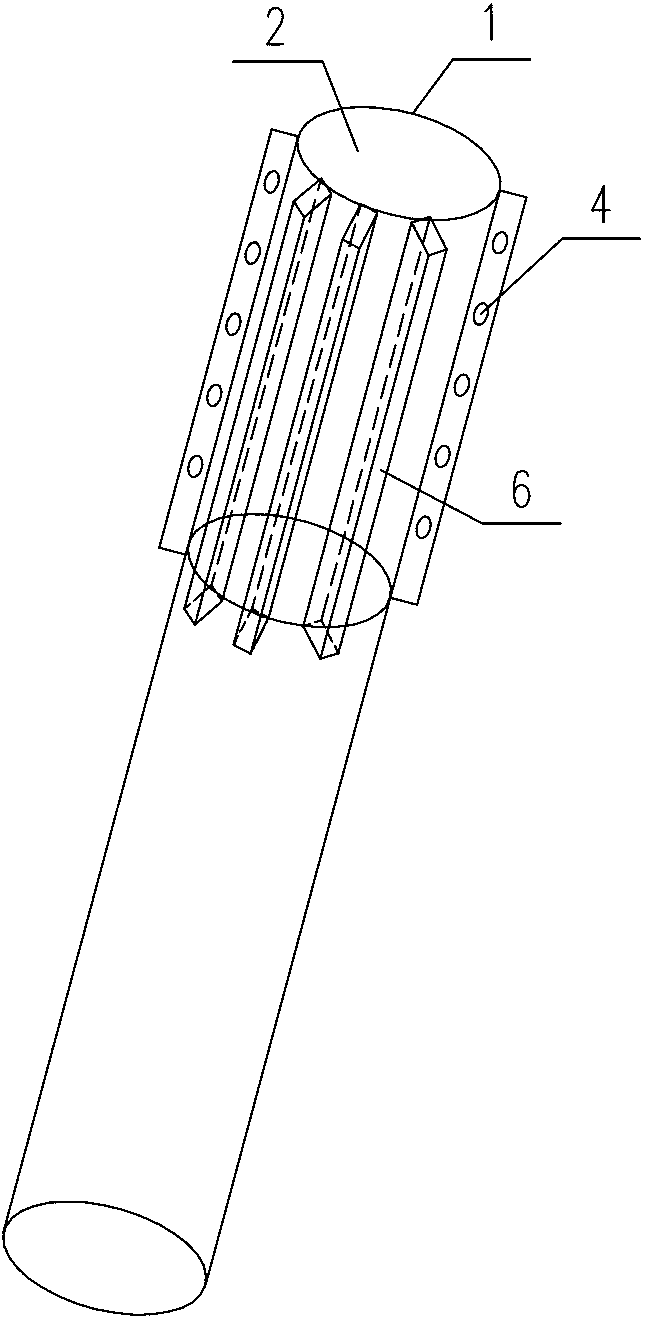

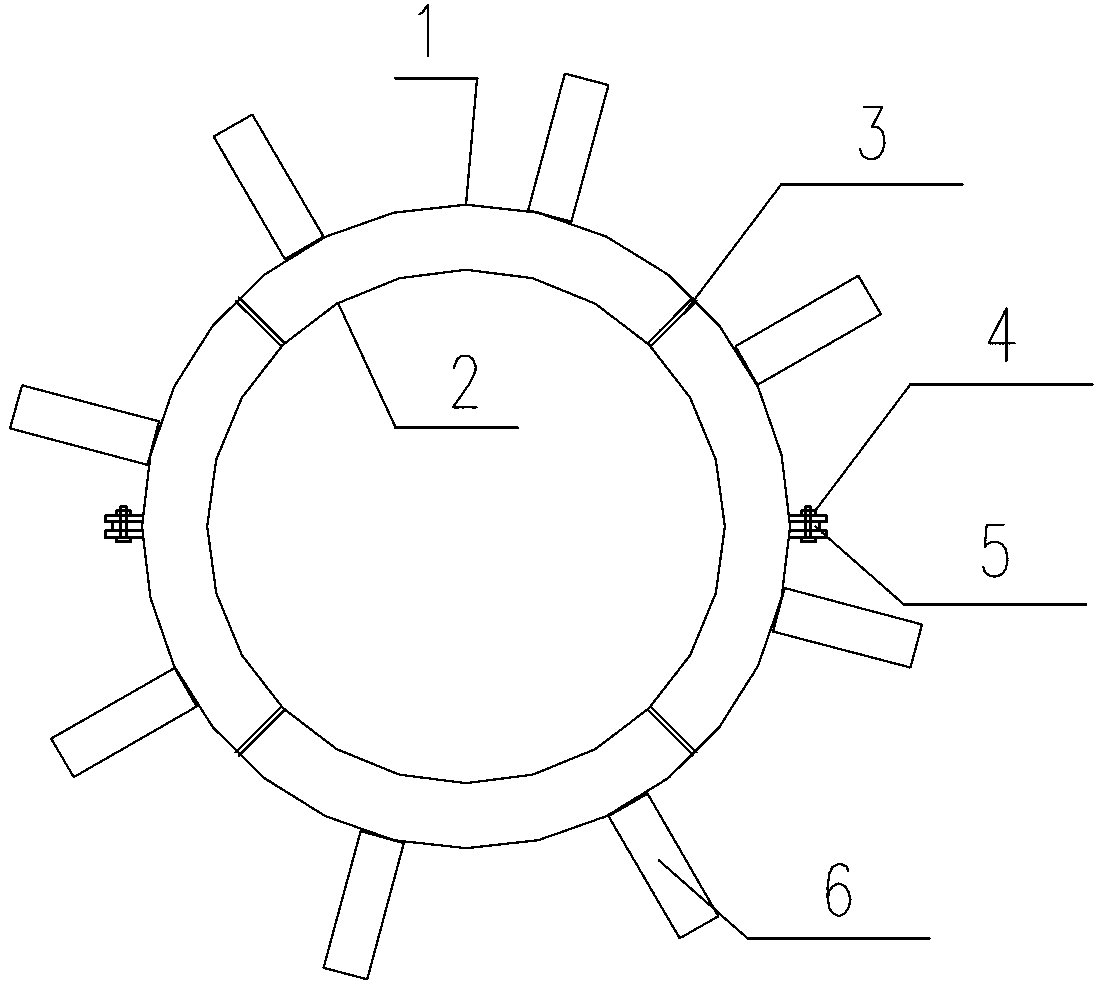

[0023] Example 1 A prefabricated pile with stiffener assembly type external restraint to prevent bending and shear damage, including a prefabricated pile 2, the pile head end of the prefabricated pile 2 is wrapped with an external restraint member 1, such as figure 1 , figure 2 As shown, the outer restraint member 1 is composed of two steel members; the outer surface of the outer restraint member 1 is welded with several stiffeners 6, and the direction of the stiffener 6 is consistent with the axial direction of the prefabricated pile 2. The axis is distributed circularly.

[0024] The two pieces of steel components are spliced together by connecting bolts 4 , the outer restraint component 1 is in the shape of a round tube, and a gasket 5 is provided between spliced ends of the two pieces of steel components.

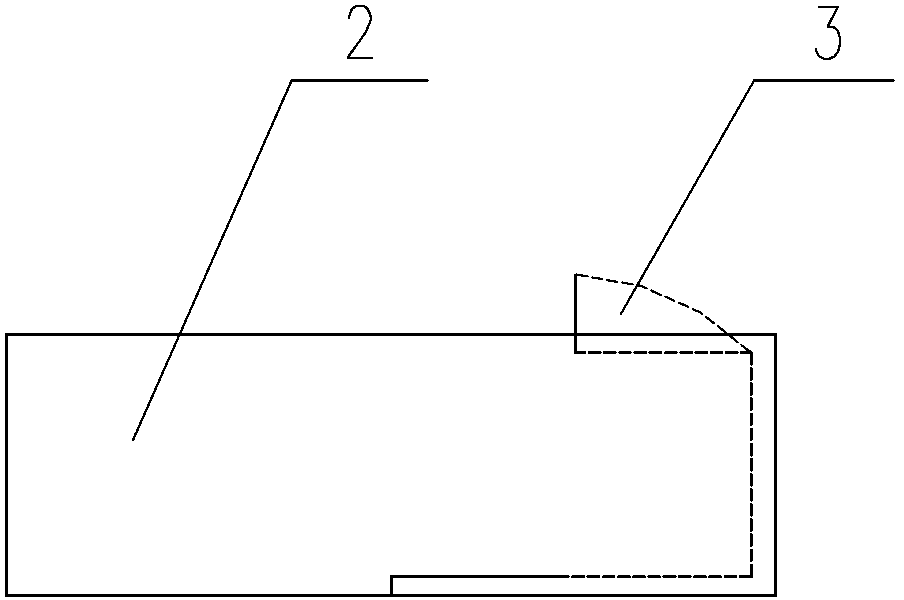

[0025] Two sets of clamping block-slot matching structures are arranged between the prefabricated pile 2 and the outer restraint member 1, and the two sets of cla...

Embodiment 2

[0027] Example 2 A prefabricated pile with stiffener assembly type external restraint to prevent bending and shear damage, such as Figure 4 As shown, the difference from Embodiment 1 lies in that: the outer constraining member 1 is in the shape of a rectangular tube; each block-slot matching structure includes two block-slot matching structures. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com