Spine-like bored concrete pile construction technique and extrusion shaping machine thereof

A technology of cast-in-situ piles and forming machines, which is applied in the direction of sheet pile walls, foundation structure engineering, drilling equipment, etc., can solve the problems of difficulty in ensuring the formation of disc-shaped spaces, increasing the workload of cleaning scum, and the bearing capacity will not be significantly improved. It is easy to ensure the compaction effect, the construction quality is easy to ensure, and the effect of automatic control is convenient

Inactive Publication Date: 2004-09-15

武维承 +1

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantages of extruding and expanding multi-branch cast-in-place piles are: (1) the equipment is huge and heavy; (2) extruding and expanding a supporting disc space requires the equipment to be transposed and the extruding and expanding process 10 times, and the construction operation is complicated, slow, and automatic. (3) Only the first expansion of the support space is really compacted, and the degree of compaction is not ideal due to the scattered soil or soil dislocation in subsequent expansions, so the improvement of bearing capacity is limited. (4) Squeezed and expanded cast-in-situ piles must be placed above pebbles, dense medium-coarse sand or other hard soil layers, otherwise they will not be squeezed in place, or the bearing capacity will not be significantly improved, which will be difficult for design and construction. Higher requirements are put forward; (5) Soil dislocation is easy to occur during extrusion and expansion in soft soil layers, and it is difficult to ensure the shape of the disc space; " phenomenon, which has a certain impact on normal construction; (7) due to repeated extrusion and expansion in a disc-shaped space and adjacent positions, the deflection of the disc cavity is relatively large, and the soil in the disc cavity is easy to fall, which not only increases the cost of cleaning scum workload, and it is difficult to guarantee the quality of construction

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

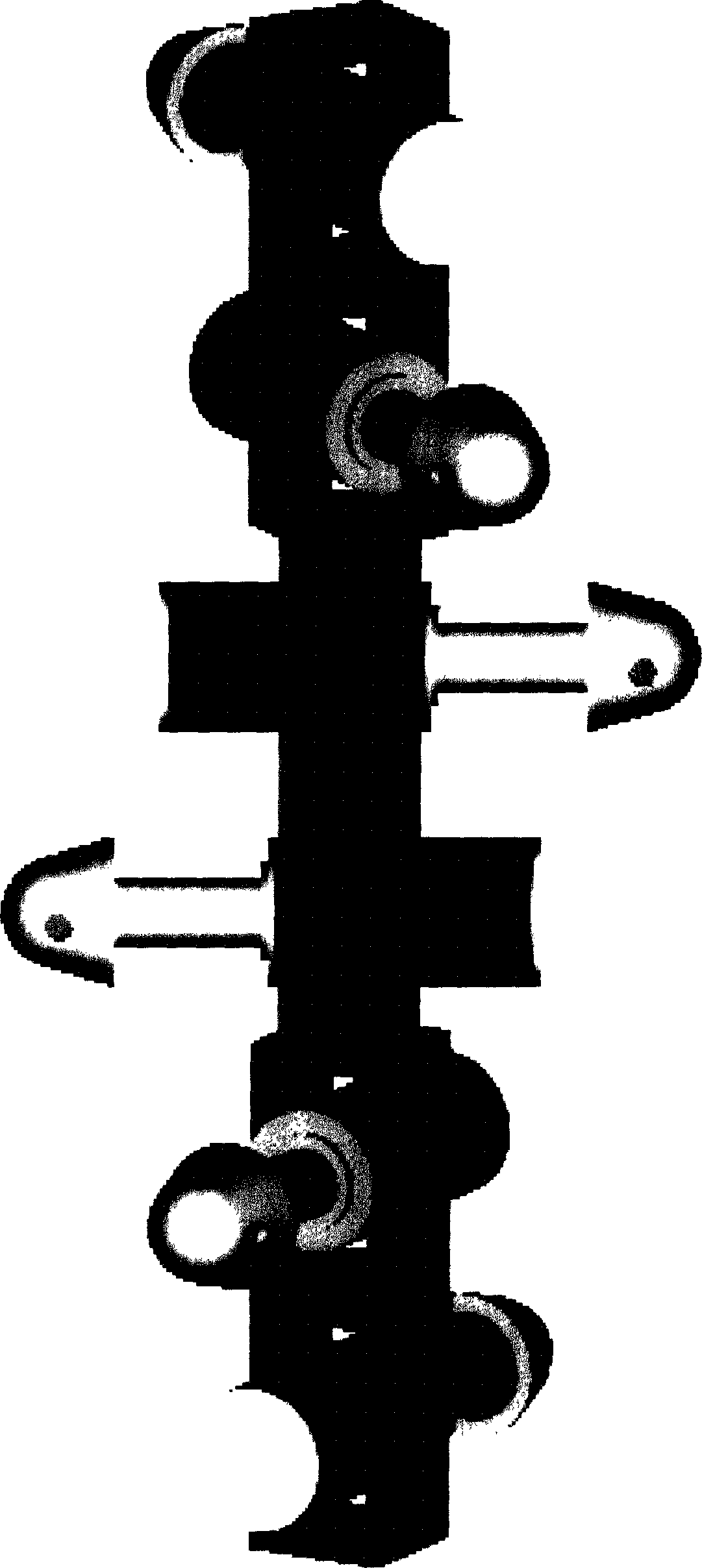

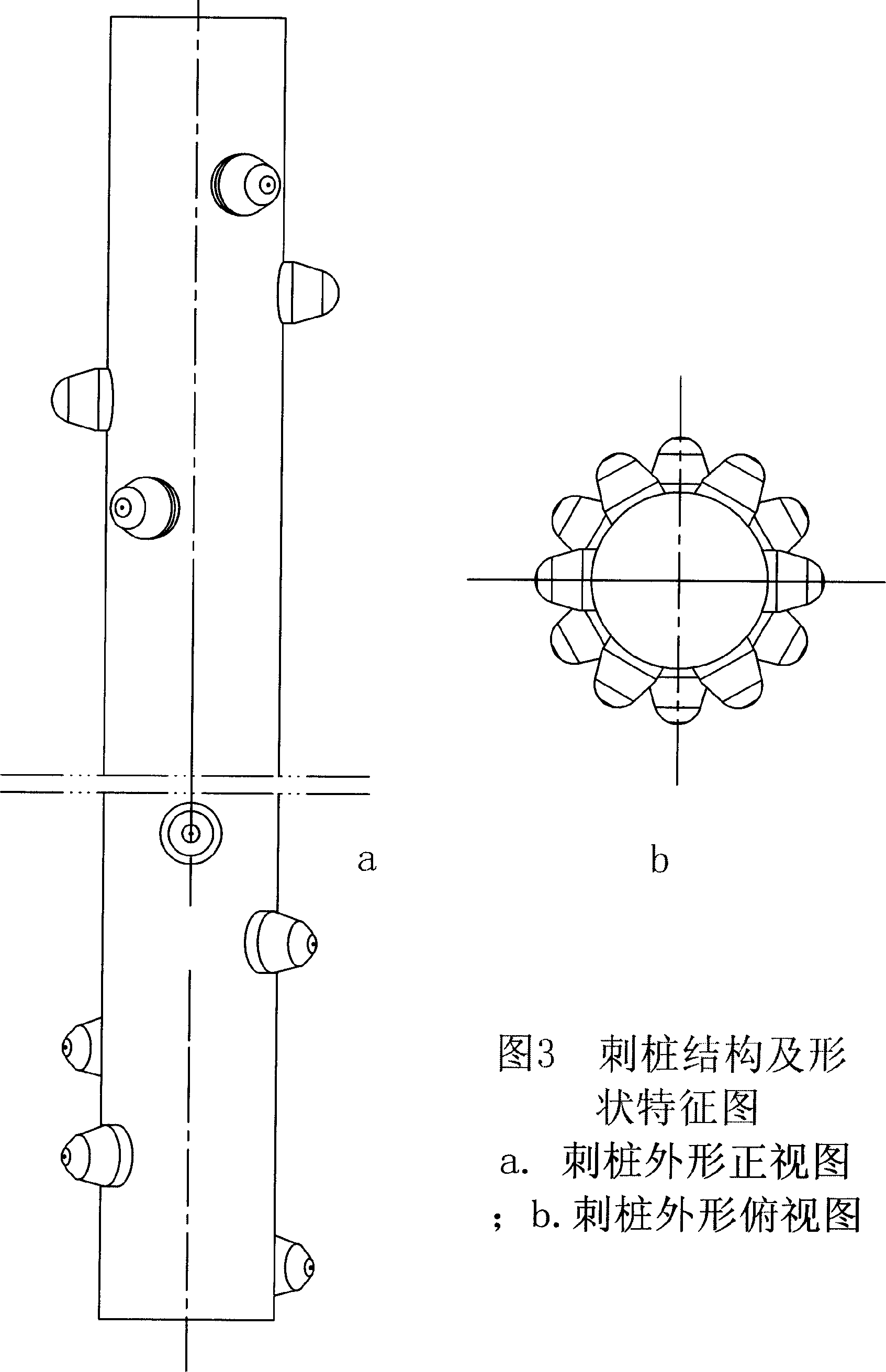

The invention is a kind of acantha pouring stake constructing technology and the forming machine, it provides a new stake shape and the constructing device. The stake is distributed with acanthas all around; the stake end resistance pressure are increased greatly, the stake side resistance pressure are increased too, thus it changes the stress mechanism of stake body, upgrades the bearing ability of stake. The forming machine is made up of six special hydraulic cylinder and the end cap; two cylinders makes up a group, they are combined up and down, and placed in reversal; three groups of hydraulic cylinder are place transversely with 60 degrees, and they are connected with bolt. When in work, the forming machine are operated, the piston pole extrudes out, the end cap squeezes the stake hole wall, it can squeeze out six acanthas spaces; adjusts the position vertically, and repeats the squeezing action, thus there will has many stake acanthas spaces. Cleans the hole ad puts down the bar cage, and pours the concrete and gets the stake.

Description

Technical field This patent relates to building foundation construction technology, production and application technology of mechanical equipment. Background technique With the gradual increase of construction projects such as high-rises, bridges and other large-scale facilities, various deep-hole cast-in-situ piles have been widely used. At present, the commonly used cast-in-place piles are straight-hole cast-in-place piles (abbreviated as straight-hole piles or bored piles). ). 1 straight hole cast-in-place pile Straight hole cast-in-situ piles were born in the 1940s. Compared with prefabricated piles, cast-in-situ piles with straight holes have obvious advantages in engineering design, engineering construction and engineering cost. With the rapid development of science and technology such as microelectronics technology, new materials, and new processes, this technology has become increasingly mature, and the level of mechanized and automated construction has been c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02D5/36E02D5/48E21B7/28

Inventor 武维承武熙

Owner 武维承

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com